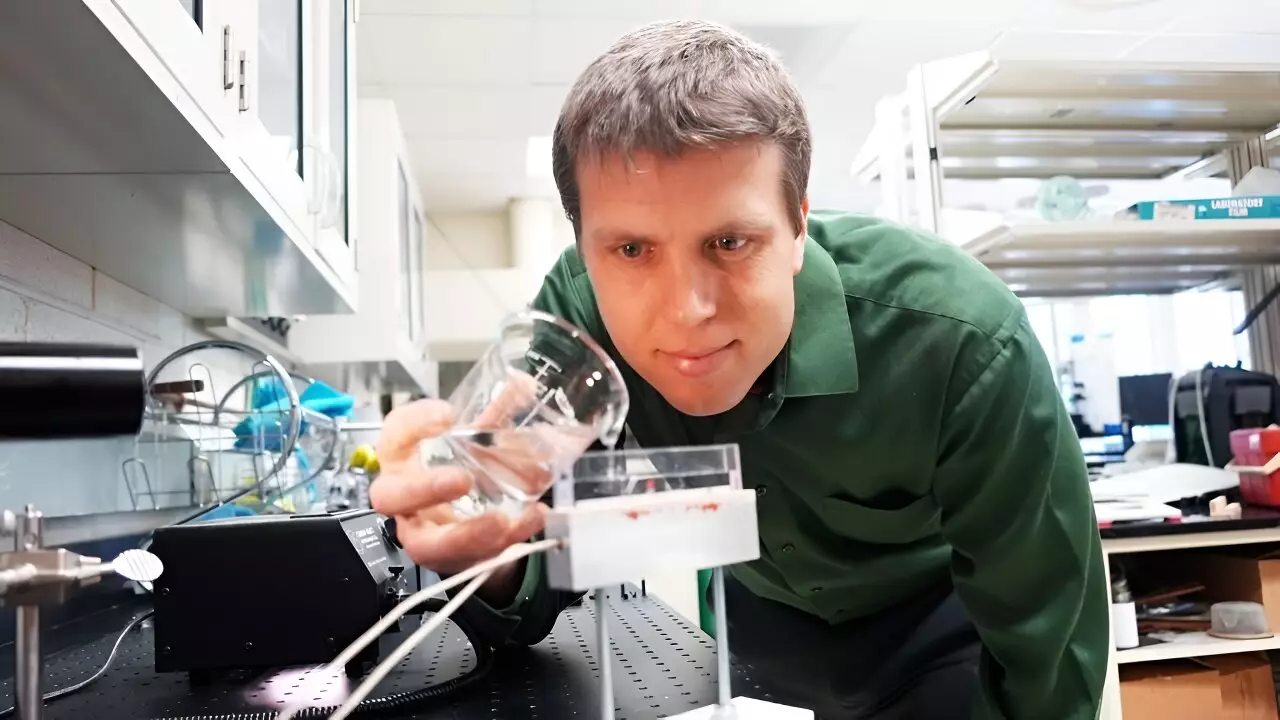

In the world of heat transfer, water has always been the primary resource for large-scale cooling operations. From data centers powering the internet to nuclear power plants energizing entire cities, the efficiency and cost-effectiveness of water-based heat transfer are essential. Jonathan Boreyko, associate professor and John R. Jones III Faculty Fellow in mechanical engineering, and his team at the Nature-Inspired Fluids and Interfaces Lab have been dedicated to discovering dynamic phenomena that can enhance water’s heat transfer capabilities. While previous research focused on water droplets propelled by surface tension and frost that jumps via electrostatics, Boreyko’s latest experimentation investigates the untapped potential of jumping bubbles during the boiling of water.

Boreyko’s exploration into the jumping behavior of water began during his Ph.D. research at Duke University, where he discovered water droplets capable of leaping due to surface tension. Inspired by this initial breakthrough, Boreyko embarked on a journey to complete a three-phase “trilogy” for jumping water. With the addition of jumping ice during frost growth, the trilogy was finally accomplished with the recent discovery of jumping bubbles during the boiling of water. Boreyko’s excitement soared when his graduate student, Hyunggon Park, shared the first videos showcasing the remarkable behavior of these jumping bubbles.

Park’s contribution to the research involved designing a micro-structured boiler that released bubbles at a fraction of their usual size, enabling a constant stream of bubbles to carry heat energy away from the surface. By creating smaller and more numerous bubbles, the team achieved a more efficient method of heat removal. Traditional boiling relies on the buoyancy of bubbles to transport the energy, but Boreyko and Park’s innovative technique ensured a continuous departure of bubbles, leading to enhanced heat transfer. The smaller size of the bubbles addressed a critical limitation associated with larger bubbles, which often impede heat removal.

The team’s breakthrough lies in their engineered surfaces, specifically an array of micro-cavities on the boiling surface that facilitate the formation and growth of bubbles. The intentional placement of closely neighboring cavities causes bubbles to merge at unusually small sizes. At this scale, surface tension exerts a significant force, propelling the bubbles to jump away from the heated surface. This mechanism closely mirrors the jumping dew droplets previously discovered by Boreyko, highlighting the effectiveness of surface tension in driving dynamic behaviors. Unlike the hydrophobic coating and fragile nanostructures required for jumping droplets, the hydrophilic surface and larger, more durable micro-cavities make the implementation of jumping bubbles more practical for a wide range of applications.

The implications of jumping bubbles in heat transfer extend beyond the realm of academic research. In settings such as data centers, where rapid heat removal is imperative, the ability to harness the jumping bubble effect can be the difference between uninterrupted operations and costly downtime. The use of uncoated metals and the presence of larger, sturdier micro-cavities reduce the fragility and expense associated with hydrophobic coatings and nanostructures required for jumping droplets. Boreyko envisions widespread applications for cooling and heat transfer, as the jumping-bubble effect offers a feasible and cost-effective solution.

While this study marks a significant milestone in understanding the fluid mechanics of jumping bubbles, there is still much work to be done. The next step involves measuring the improved heat transfer achieved through jumping-enhanced boiling across various temperature ranges and surface geometries. This comprehensive analysis will provide crucial insights into the full potential of jumping bubbles and further refine the understanding of their practical applications.

Jonathan Boreyko and his team’s groundbreaking research on jumping bubbles has opened up new horizons for the field of heat transfer. By combining the forces of heat and surface tension, they have unlocked a more efficient and cost-effective method for removing heat from surfaces. The engineered surfaces they have developed bring jumping bubbles closer to real-world implementation, with potential applications ranging from data centers to industrial cooling systems. As the journey continues, and more is learned about the fluid mechanics and heat transfer capabilities of jumping bubbles, the future of heat transfer holds exciting possibilities.

Leave a Reply