In recent years, the field of robotics has made significant advancements in enhancing the collaboration between humans and robots in various industrial settings. One emerging concept is the use of digital twin systems, virtual models that accurately replicate physical objects or components being manufactured. Researchers from Nanjing University of Aeronautics and Astronautics in China have developed a novel digital twin system aimed at improving the cooperation between human and robotic agents in manufacturing settings. This article explores the functionality and potential benefits of this new system.

The traditional approach to constructing a human digital twin model in industrial settings involves motion capture devices that require personnel to wear cumbersome equipment. This method contradicts the principle of flexible interaction and can impede worker productivity. Moreover, the separation of humans and robots in a unified space poses challenges in perceiving and understanding the overall environment. To address these limitations, Zhang, Ji, and their team propose a digital twin system for Human-Robot Collaboration (HRC).

The digital twin system developed by Zhang, Ji, and their colleagues creates a virtual replica of a collaborative scene involving a human and a robot agent. It then plans and executes effective collaborative strategies in a real-world environment. Unlike previous digital twin systems that rely on motion capture data, this system incorporates a human mesh recovery algorithm to reconstruct occluded human bodies. This feature overcomes the limitations of occlusions, where objects or agents of interest are outside the sensor’s field of view or hidden behind obstacles.

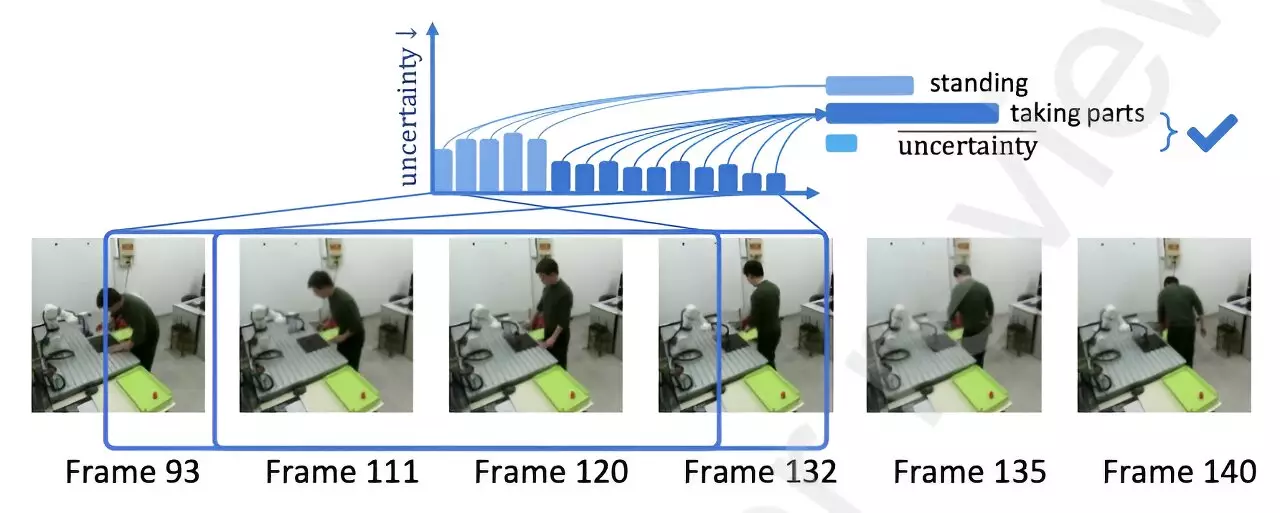

To further enhance the performance of the system, the research team introduced an uncertainty estimation technique. This technique manages the risk associated with the action recognition algorithm, which is responsible for identifying different human actions. By controlling the potential for errors, the system ensures more accurate collaboration between humans and robots. In a series of laboratory experiments using an industrial robot, the new digital twin system demonstrated superior results compared to baseline methods.

The researchers also conducted a case study involving component assembly to validate the feasibility and effectiveness of their HRC system. The positive outcomes observed in their experiments suggest that this new digital twin system can significantly enhance the collaboration between robots and humans in various manufacturing and industrial tasks. The system’s potential applications extend beyond the lab, as it could soon be implemented in other industrial robots for real-world use. Further testing and experimentation will be crucial before widespread adoption can occur.

The development of a new digital twin system by Zhang, Ji, and their team holds promise for revolutionizing human-robot collaboration in manufacturing settings. By overcoming the limitations of current methods and incorporating advanced algorithms, this system paves the way for more efficient and intuitive interactions between humans and robots. As the field of robotics continues to evolve, the integration of digital twin systems may become a standard practice, benefiting industries worldwide.

Leave a Reply