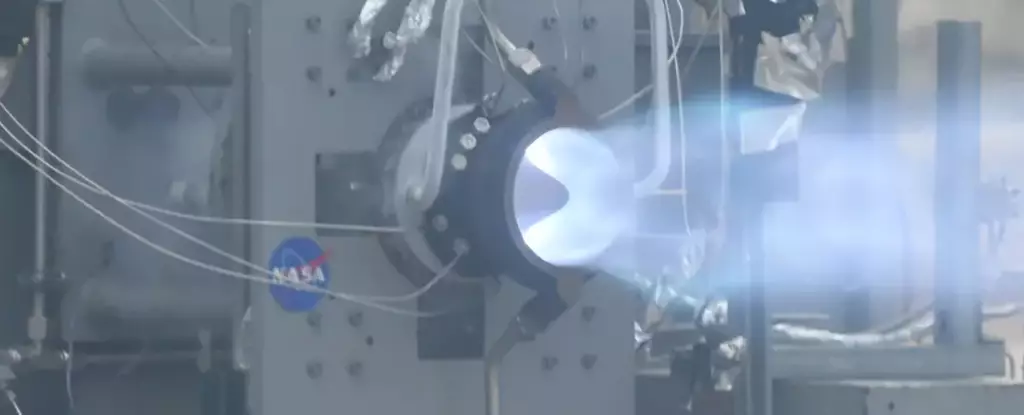

As humanity sets its sights on Mars, the challenges of speedy and long-distance space travel come to the forefront. NASA, taking a significant step forward, recently announced the successful testing of an innovative rocket engine that could propel us to the Red Planet. By putting the prototype Rotating Detonation Rocket Engine (RDRE) through rigorous testing at the NASA Marshall Space Flight Center in Alabama, the agency achieved remarkable results. This breakthrough technology achieved a record-breaking thrust of 25,810 newtons (5,800 pounds) for an impressive 251 seconds. The RDRE outperformed its 2022 record of 17,800 newtons of thrust in under a minute. With these results validated early in 2023, NASA aims to develop a fully reusable 44 kilonewton class RDRE that surpasses traditional liquid rocket engines in terms of efficiency and functionality.

Leading the RDRE project at the Marshall Space Flight Center, combustion devices engineer Thomas Teasley hails the engine as a game-changer in design efficiency. What sets the RDRE apart is its utilization of a rotating detonation within a ring-shaped channel. The engine is fueled by a mixture of fuel and oxygen, ignited by each passing explosion. While the technology has been in development since 2020, it has only now proven stable and manageable enough for use in actual space exploration missions.

Crucially, the RDRE also boasts reduced propellant fuel consumption and simpler machinery compared to conventional rocket engines. This breakthrough translates into cost reductions for space exploration. Additionally, the ability to travel longer distances becomes attainable, marking a significant advancement in our exploration of space. The utilization of 3D printing techniques has further contributed to the RDRE’s success. NASA engineers have manufactured strong machine parts capable of withstanding extreme heat and pressure, crucial to the RDRE’s design.

The test results have provided NASA engineers with valuable insights into scaling and adaptability. This newfound understanding enhances the potential for the RDRE’s application across varying thrust levels, engine systems, and mission classes. It opens up possibilities for customization and optimization based on mission requirements. NASA’s goal of landing humans on Mars by the 2030s hinges on addressing numerous challenges. However, efficient propulsion systems, such as the RDRE, offer a promising solution to overcome one of the most significant obstacles in space exploration.

The successful testing of the RDRE marks a remarkable milestone in humanity’s pursuit of interplanetary travel. This advancement in rocket technology brings us one step closer to realizing NASA’s vision of sustainable Mars exploration. Thomas Teasley expressed his enthusiasm, stating, “It demonstrates we are closer to making lightweight propulsion systems that will allow us to send more mass and payload further into deep space, a critical component to NASA’s Moon to Mars vision.” The RDRE’s improved efficiency and reduced fuel consumption not only push the boundaries of our exploration capabilities but also enrich our understanding of the cosmos.

Conclusion

The journey to Mars is no longer a distant dream but an achievable reality. With the successful testing of the Rotating Detonation Rocket Engine, NASA has propelled humankind forward in our quest for interplanetary travel. The RDRE’s ability to provide high thrust at reduced fuel consumption and its adaptability make it a vital component of future space missions. As we continue to overcome the hurdles of space exploration, advancements in rocket technology pave the way for a new era of scientific discovery and the pioneering of new frontiers.

Leave a Reply