Aerodynamic engineering has seen a significant transformation with the integration of deep learning tools in the design process for planes, cars, and ships. These technological advancements have not only enhanced the fuel efficiency of these vehicles but also improved their structural refinement. The recent development of a computational model, utilizing neural network architecture, has taken the science of reproducing airflow to new heights. This model, as reported by researchers at KTH Royal Institute of Technology, along with collaborators in the U.S. and Spain, has proven to provide accurate predictions while reducing time, cost, and energy expenditure.

The newly introduced computational model presented in Nature Communications focuses on predicting aerodynamic drag with a high degree of accuracy while significantly lowering the computational cost. This model, based on neural network architecture, is designed as a reduced order model (ROM). The primary objective of a ROM is to retain essential features of complex simulations while eliminating less significant details. This streamlined approach aims to enhance computational efficiency and facilitate multiple scenario runs at a low cost, which is crucial in design engineering.

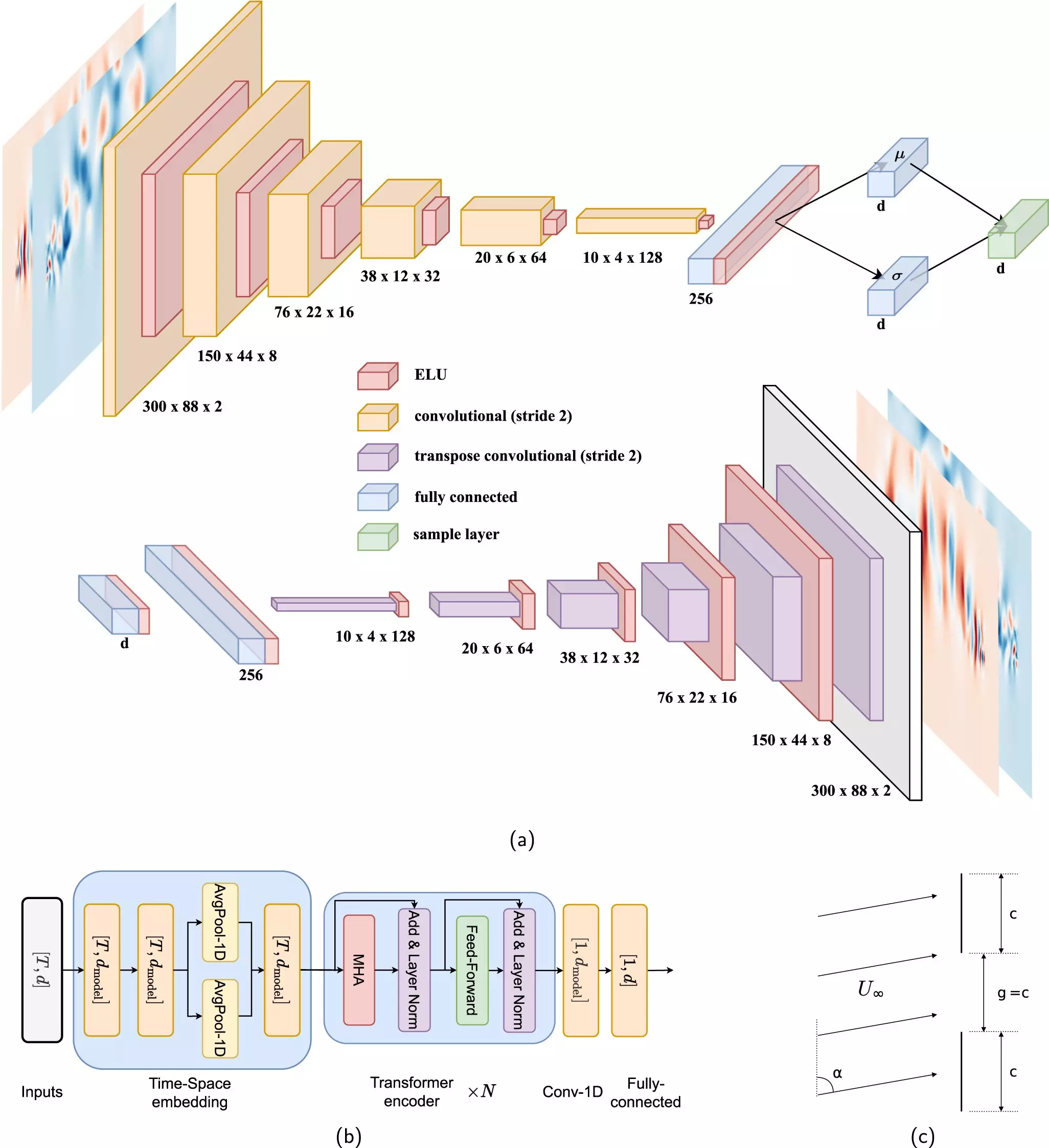

Neural networks play a pivotal role in elevating the capabilities of the new computational model. Unlike traditional linear computation methods used in fluidics modeling, neural networks have the ability to learn and map intricate relationships between input and output data. While neural networks do not possess cognitive abilities to think on their own, they excel at capturing complex patterns and correlations within the data. This feature is especially beneficial when predicting and modeling airflow around intricate structures like airplane wings or train engines, where traditional linear models fall short.

The neural network-based model introduced by the researchers at KTH Royal Institute of Technology can achieve a prediction accuracy of 90% or higher with relatively low processing complexity. In comparison, traditional linear models like proper-orthogonal decomposition (POD) and dynamic-mode decomposition (DMD) struggle to match this level of accuracy due to their simplistic representation of airflow dynamics. The ability of neural networks to capture non-linear relationships enables the model to provide more precise predictions, outperforming linear models that rely on straight-line approximations.

One of the key implications of leveraging deep learning technology in aerodynamic control is the potential for significant reductions in aerodynamic drag, which is a major contributor to global emissions. By implementing this technology, drag reductions of 20% to 50% can be achieved, leading to a substantial environmental impact. Improving aerodynamic efficiency not only benefits the environment but also plays a crucial role in shaping the future of sustainable transportation and emission reduction efforts.

The integration of deep learning tools and neural network-based models in aerodynamic engineering represents a significant advancement in predictive modeling and design optimization. The innovative approach presented by researchers at KTH Royal Institute of Technology showcases the potential of deep learning technology to revolutionize the way we approach aerodynamic design and efficiency. By harnessing the power of neural networks, engineers can make more accurate predictions, enhance aerodynamic performance, and contribute to a more sustainable future for transportation industry.

Leave a Reply