Rechargeable solid-state lithium batteries have been hailed as the next generation of energy storage solutions, promising to revolutionize the way we power our electronic devices. However, despite their numerous advantages, such as enhanced energy density and safety, these batteries are not without their environmental challenges. The current recycling methods for solid-state lithium batteries are limited, with most components going to waste. A team of researchers from Penn State University may have found a solution to this pressing issue, which could potentially pave the way for a more sustainable future for this emerging technology.

Traditionally, recycling solid-state batteries has been a complex and inefficient process. The mixing of core battery components during recycling results in a “black mass,” which contains valuable materials needed for batteries but is difficult to separate. Solid-state batteries exacerbate this issue with the use of solid electrolytes, which become intertwined with the black mass. To address this challenge, the researchers proposed a novel approach to reconfigure the design of solid-state batteries for easier recycling.

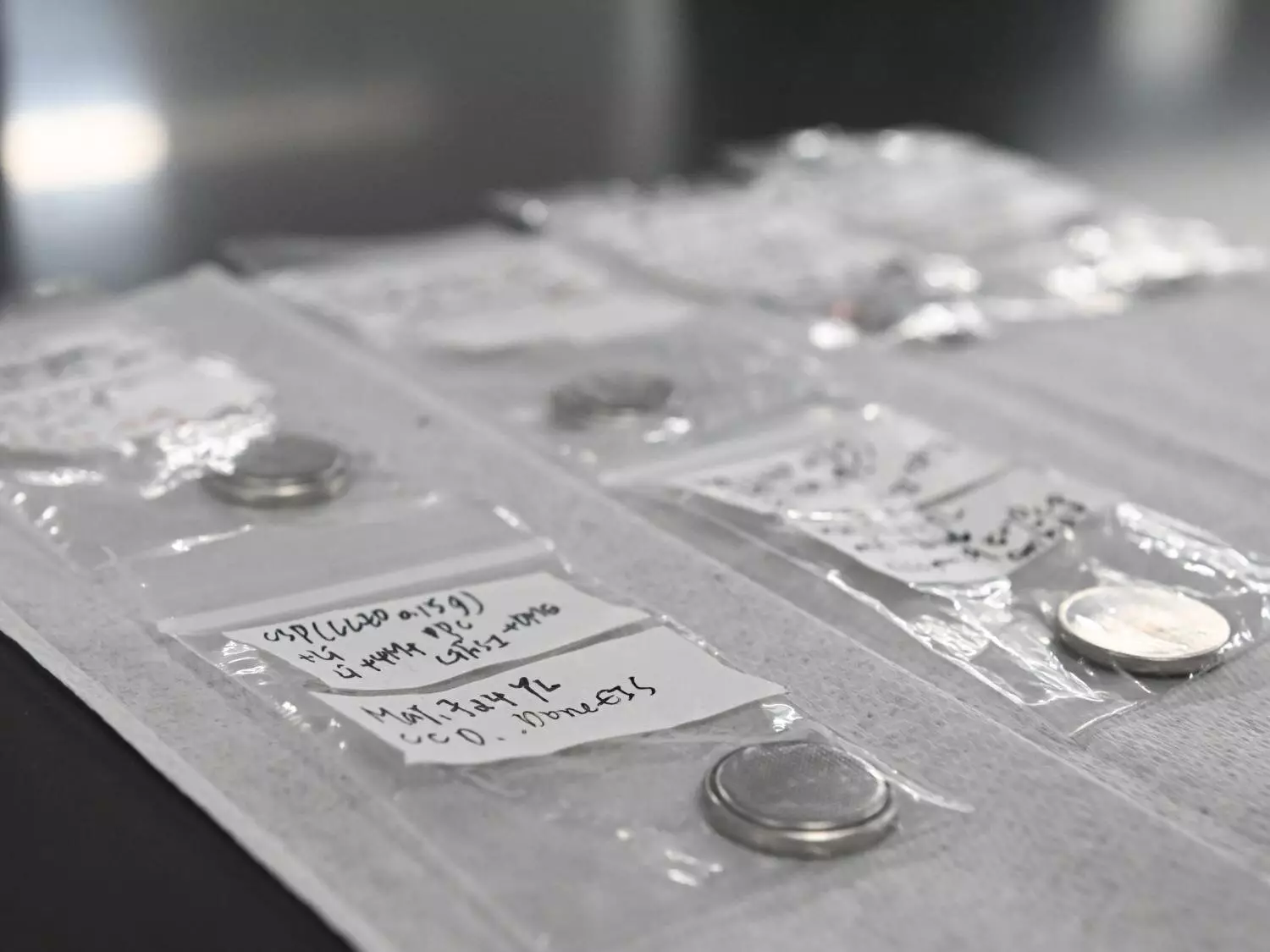

The key innovation proposed by the Penn State researchers was the insertion of two polymer layers at the interfaces between the electrode and the electrolyte in solid-state lithium batteries. By dissolving these polymer layers during the recycling process, the electrode and electrolyte can be easily separated, allowing for more efficient recycling of the battery components. This groundbreaking design element could potentially revolutionize the way solid-state batteries are recycled, minimizing waste and maximizing resource recovery.

In addition to the polymer layers, the researchers utilized a cold sintering technique to combine recovered metals and electrodes from the recycled batteries. Developed in 2016, cold sintering involves the combination of powder-based materials into dense forms at low temperatures through applied pressure using solvents. By incorporating cold sintering into the recycling process, the researchers were able to reconstruct the battery with recovered components, ensuring that the entire battery could be recycled and reused multiple times.

Following the reconstruction of the battery, the researchers conducted performance tests to evaluate its efficiency. Remarkably, the reconstructed battery achieved between 92.5% and 93.8% of its original discharge capacity, demonstrating the viability of the recycling process. These promising results suggest that the proposed design modifications and recycling techniques could play a crucial role in the commercialization of recyclable solid-state lithium batteries in the future.

As the demand for rechargeable batteries continues to rise, the importance of developing sustainable recycling solutions for these technologies cannot be understated. The innovative research conducted by the Penn State team offers valuable insights and ideas for designing recyclable versions of solid-state lithium batteries. By addressing the environmental challenges associated with these batteries, we can move closer to a more sustainable and efficient energy storage system that benefits both consumers and the planet. The future of rechargeable solid-state lithium batteries looks brighter with each new advancement in recycling technology.

Leave a Reply