The School of Engineering at the Hong Kong University of Science and Technology (HKUST) has recently conducted a groundbreaking study that introduces a new method for producing complex cellular ceramics. This innovative approach, outlined in the journal Nature Communications, has the potential to transform the design and processing of ceramic materials, with implications for a wide range of industries including energy, electronics, and biomedicine.

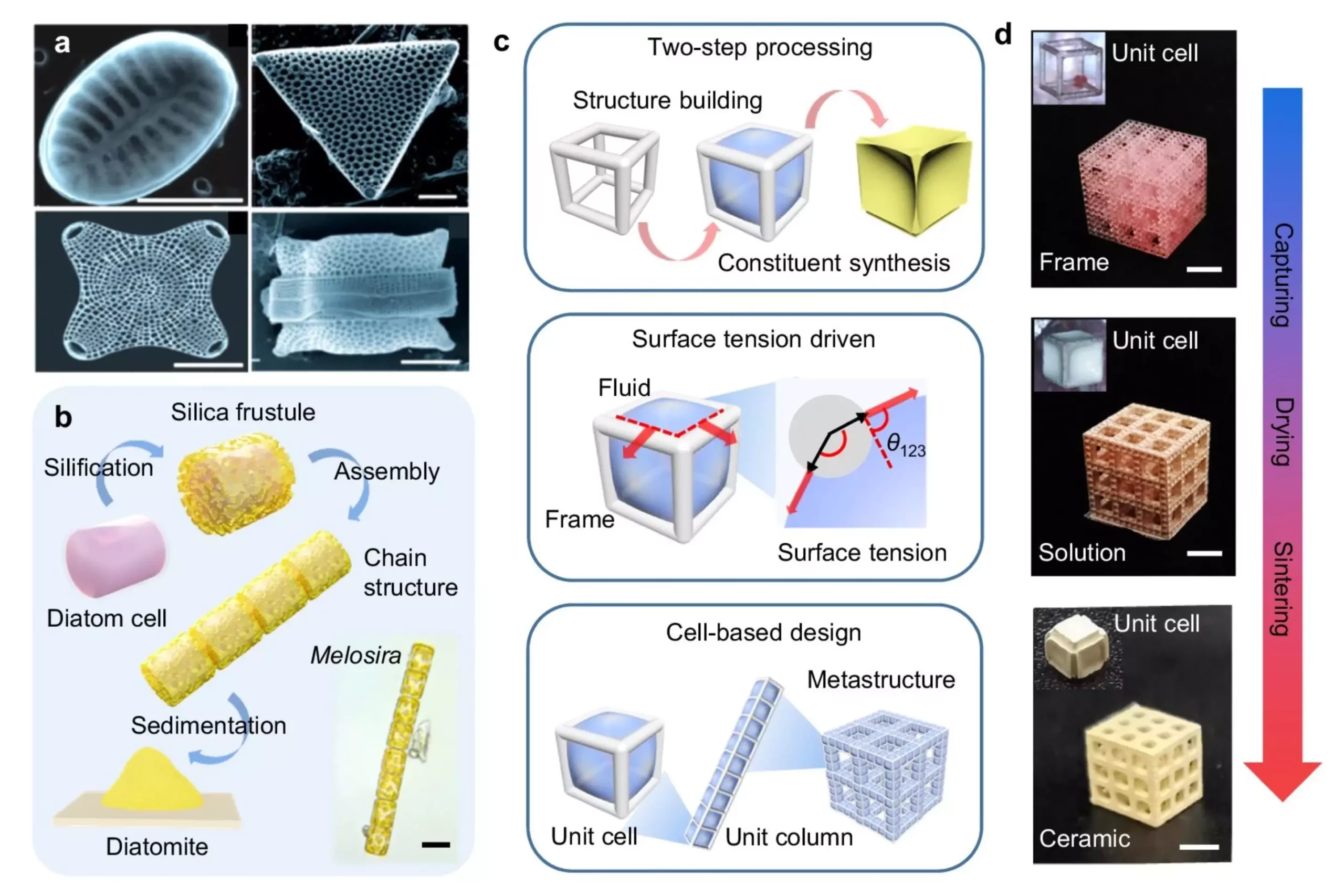

Associate Professor Yang Zhengbao and his research team at HKUST developed a Surface Tension-Assisted Two-Step (STATS) processing strategy to fabricate cellular ceramics with intricate 3D configurations. This method involves two key steps: creating cell-based organic lattices using additive manufacturing, and filling these lattices with the necessary constituent materials. One of the main challenges addressed by the team was controlling the liquid geometry during the manufacturing process.

To tackle the issue of liquid geometry control, the researchers harnessed the natural phenomenon of surface tension. By leveraging surface tension to capture and pin fluids within the prepared lattices, they were able to achieve precise control over the liquid geometry, resulting in the successful production of cellular ceramics with high accuracy.

The STATS approach separates ingredient synthesis from architecture building, allowing for the programmable manufacturing of cellular ceramics with varying cell sizes, geometries, densities, meta-structures, and constituent elements. This level of programmability makes the method applicable to both structural and functional ceramics, expanding its potential for diverse applications.

Researchers also examined the piezoelectric performance of cellular piezoceramics produced using the STATS approach. They found that this method led to a decrease in micropores and an improvement in local compactness, resulting in globally porous yet locally compact cellular piezoceramics. The high piezoelectric constant achieved, even at very high overall porosity levels, demonstrates the effectiveness of the novel manufacturing technique.

Professor Yang drew inspiration from diatoms, single-celled algae known for their precise silica cell walls. Through a genetically programmed biomineralization process, diatoms construct highly intricate structures with diverse morphology, shapes, geometries, and pore distributions. This bio-inspired approach was instrumental in overcoming the limitations of conventional manufacturing methods and enabling the creation of complex ceramic architectures.

The novel method introduced by Professor Yang and his team has the potential to revolutionize the manufacturing of cellular ceramics, with implications for a wide range of industries. From filters and sensors to actuators, robotics, battery electrodes, solar cells, and bactericidal devices, the programmable, geometrically complex ceramic architectures created using this approach hold promise for a variety of applications.

Overall, the study conducted by the HKUST School of Engineering showcases the power of innovation in transforming traditional manufacturing processes and opening up new possibilities for materials design and application. With a focus on precision, control, and programmability, the STATS approach represents a significant step forward in the field of ceramic production.

Leave a Reply