The increasing industrial activity around the globe has exacerbated environmental challenges, particularly regarding the emission of harmful gases. Among these pollutants are nitrogen oxides (NOx), specifically nitric oxide (NO) and nitrous oxide (N2O), which pose significant risks to both human health and ecosystems. Effective management of these toxic emissions has become a critical concern for industries worldwide, leading to the development of advanced catalytic materials to mitigate their impact. One promising avenue of research has emerged from the Paul Scherrer Institute (PSI) in Switzerland, focusing on zeolites—natural or synthetic minerals characterized by their complex nano-porous structure.

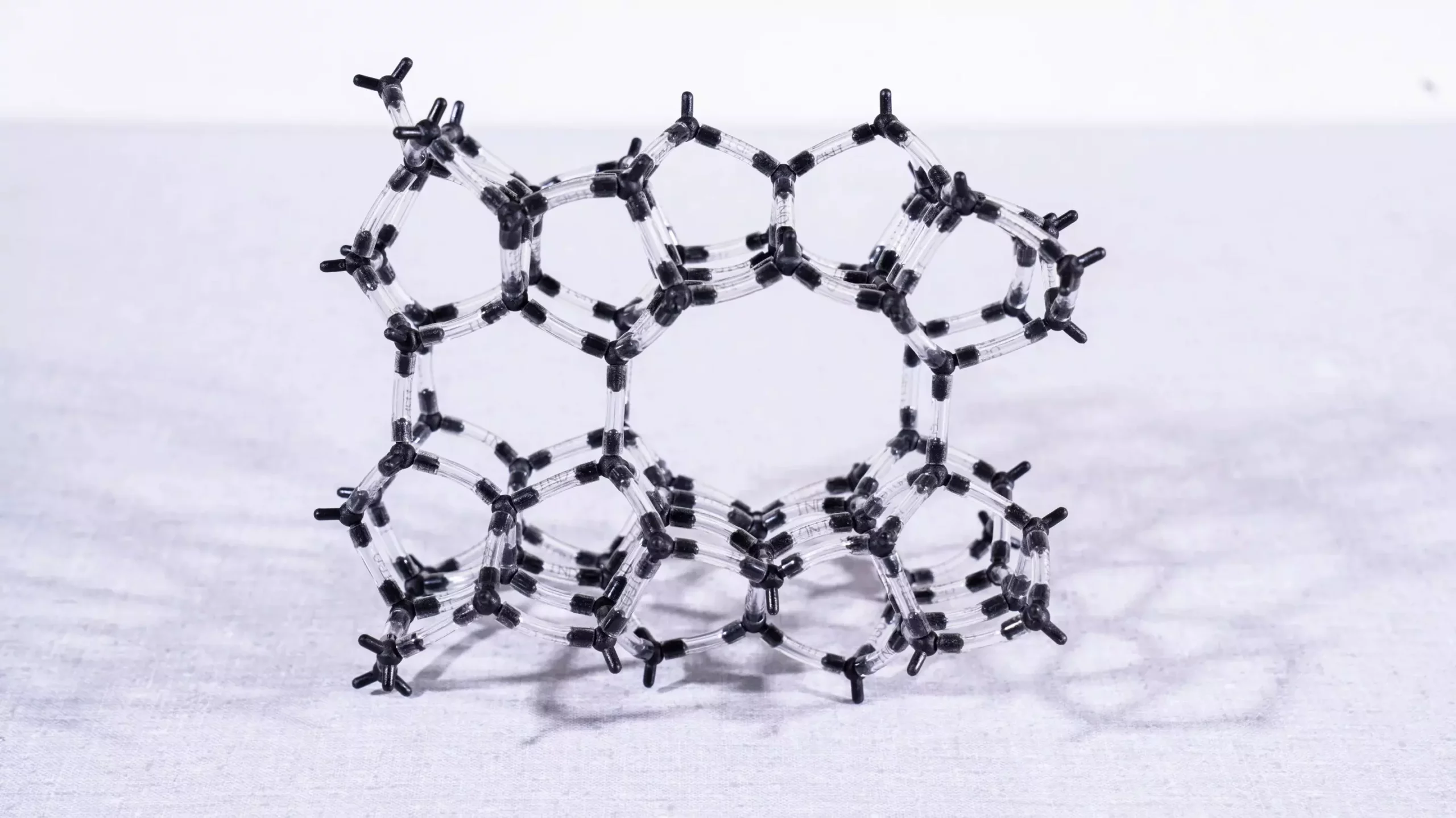

At the heart of the research is the intricate architectural framework of zeolites, composed of aluminum, silicon, and oxygen atoms. This unique structure not only provides the framework for catalytic activity but also allows for the inclusion of metal ions, such as iron, which enhance the zeolite’s ability to facilitate chemical reactions. The zeolite’s ability to capture and convert harmful nitrogen oxides into harmless species is largely attributed to these iron species.

Recent findings published in *Nature Catalysis* reveal that the positioning and interactions of individual iron atoms within the zeolite framework are paramount for efficacy. When zeolites are doped with iron, each iron atom can exist in various configurations—single atoms or as clusters—and it is vital to elucidate which forms are the most effective for catalyzing the reduction of NOx.

Collaborative efforts between researchers at PSI and CASALE SA, a Swiss chemical company, have yielded significant insights into the performance of these zeolite catalysts. Leading the study, Filippo Buttignol employed a combination of advanced spectroscopic techniques to unravel the complexities of the catalytic process. Using the Swiss Light Source (SLS), he conducted X-ray absorption spectroscopy to obtain a comprehensive view of all iron species during the reaction. This was complemented by electron paramagnetic resonance spectroscopy in partnership with ETH Zurich, which helped isolate the contributions of different iron configurations.

Moreover, infrared spectroscopy enabled the researchers to analyze the molecular characteristics of the iron species in real-time during the catalytic activity. Together, these methods painted a detailed picture of how specific arrangements of iron are necessary for effective catalysis.

The analysis indicated that the catalytic reactions depend on two adjacent iron atoms within the zeolite framework, which must interact in a very specific manner to facilitate the conversion of NO and N2O. The iron atom responsible for processing nitrous oxide has a square arrangement of four surrounding oxygen atoms, while the atom that interacts with nitric oxide features a tetrahedral configuration. This precise geometric alignment is crucial; it fosters a cooperative mechanism where the two iron species communicate and facilitate the redox reactions essential for catalysis.

These findings elucidate not only the scientific principles governing catalyst activity but also the potential for intentional design improvements. As Davide Ferri points out, understanding the locations where reactions occur allows for the optimization of catalyst manufacturing, fostering more efficient industrial applications.

The significance of effectively reducing nitrogen oxides cannot be overstated, given their deleterious effects on human health and the environment. Nitric oxide contributes to the formation of acid rain, while nitrous oxide, a potent greenhouse gas, bears a climate impact up to 300 times greater than carbon dioxide on a per-molecule basis. As such, advancements in zeolite-based catalysts not only promise to enhance operational efficiency in industries like fertilizer production—which generate these emissions—but also help alleviate broader environmental challenges.

Given that zeolite catalysts can be manipulated at the atomic level, future research will likely hone in on customizing these materials to maximize their effectiveness in specific applications. By engineering the distribution and arrangement of iron atoms intentionally, it may be possible to create more effective catalysts that operate under a wider range of conditions. This proactive approach paves the way for innovations that could lead to more sustainable industrial practices and a reduced environmental footprint.

The collaborative research at PSI highlights an exciting frontier in catalytic science, where the melding of advanced spectroscopy and zeolite chemistry holds the promise for more significant strides in combating industrial pollution while prioritizing environmental preservation.

Leave a Reply