The quest for alternative battery technologies is pressing as the demand for energy storage solutions escalates. With a rise in electric vehicles and renewable energy sources, the limitations of lithium-ion batteries have become apparent. Researchers are pivoting toward sodium-ion batteries, which utilize sodium (Na) instead of lithium (Li). A significant breakthrough has recently emerged from a research team led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Nano Hybrid Technology Research Center of the Korea Electrotechnology Research Institute (KERI)—a game-changing process for producing hard carbon anodes using microwave induction heating.

Sodium-ion batteries offer a beacon of hope due to the abundance of sodium, which is found in everything from salt to seawater, making it far more accessible than lithium. Unlike lithium, which is increasingly hard to mine and refine, sodium’s higher availability could pave the way for more sustainable battery technologies. Additionally, sodium-ion batteries exhibit greater stability due to sodium’s lower reactivity, allowing for enhanced resilience in various conditions, including lower temperatures. Despite these advantages, sodium-ion batteries face considerable hurdles, notably lower energy density and shorter lifespan. These limitations arise from the complexities involved in synthesizing suitable anode materials.

The crux of the innovation is centered on the necessity of hard carbon, which offers the appropriate interlayer spacing for sodium ions as compared to conventional graphite. Hard carbon must be synthesized rather than mined, requiring intricate and high-temperature processes—often exceeding 1,000°C—in an oxygen-free environment. This “carbonization” process presents significant economic and environmental challenges, hindering the broader integration of sodium-ion batteries into the market. Researchers have been emphasizing these hurdles as imperative obstacles that need to be addressed for sodium-ion technology to become commercially viable.

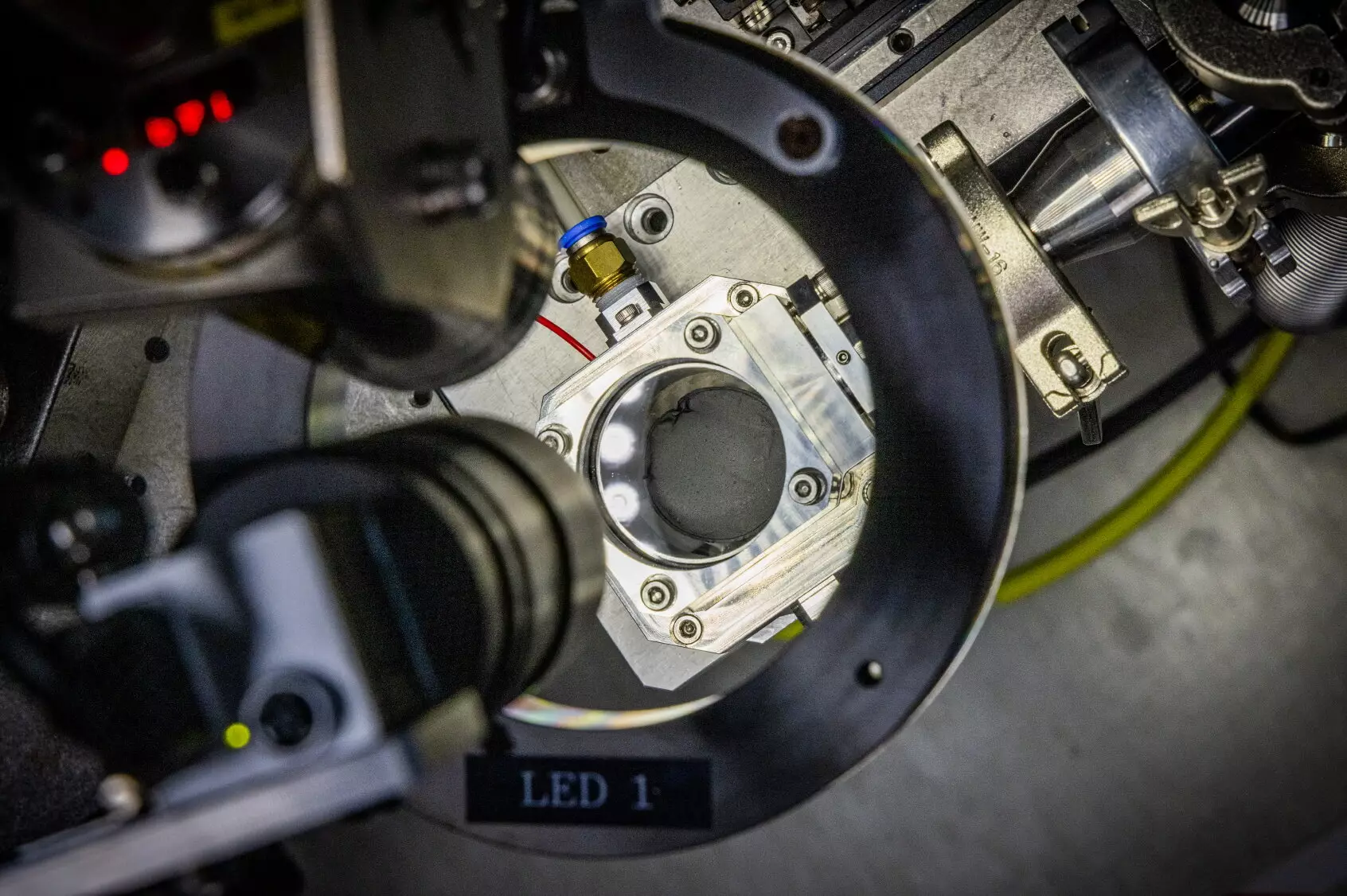

Dr. Kim and Dr. Park’s team has taken a novel approach by employing microwave induction heating, reminiscent of what is commonly used in home kitchens. This method allows them to heat polymer mixtures integrated with carbon nanotubes in just 30 seconds, propelling the temperature beyond 1,400°C. This rapid processing method is not only a significant time-saver but also mitigates energy consumption when compared to traditional carbons synthesis methods.

Leveraging years of research with microwave technology, KERI developed a technique that uniformly heat-treats thin films composed of conductive materials. Their expertise in this area has been instrumental in overcoming the barriers commonly faced in sodium-ion battery material production. This breakthrough places KERI at the forefront of advancing carbon nanomaterials technology in industrial applications.

The Breakthrough Paper and Future Directions

The implications of this research are profound, as indicated by the team’s publication in the esteemed Chemical Engineering Journal. The rigorous research, conducted by student researchers Geongbeom Ryoo and Jiwon Shin, highlights a collaborative approach that leverages academic insights in technology to solve real-world problems. Dr. Park succinctly expressed the growing industry interest in sodium-ion batteries due to enhanced safety compared to lithium-ion options, particularly in light of concerns raised by recent battery-related fires. Dr. Kim also pointed out the tremendous potential of their microwave technology in facilitating efficient carbon production as a stepping stone towards more widespread sodium-ion battery commercialization.

Looking ahead, the researchers plan to optimize the performance of their anodes further and explore the scalability of their production technology. The potential applications of microwave induction heating extend beyond sodium-ion batteries, opening possibilities for advancing technologies related to all-solid-state batteries, which require high-temperature processing themselves.

The Road to Commercialization

Recognizing the commercial potential, KERI has already initiated steps for a domestic patent application, signaling its intent to engage with the broader energy storage industry. The prospect of technology transfer to industry partners could invigorate the market, driving collaboration while ensuring that the innovations benefit the public. The team’s vision aligns with the anticipated growth of the energy storage sector, where sustainable and efficient solutions are paramount as the world shifts to a greener future.

The efforts of Dr. Kim, Dr. Park, and their team represent a significant leap forward in the field of sodium-ion battery technology. By tackling the intricacies of anode material production through innovative processes like microwave induction heating, they pave the way not just for improved battery technologies but also for sustainable, efficient energy storage solutions in the years to come.

Leave a Reply