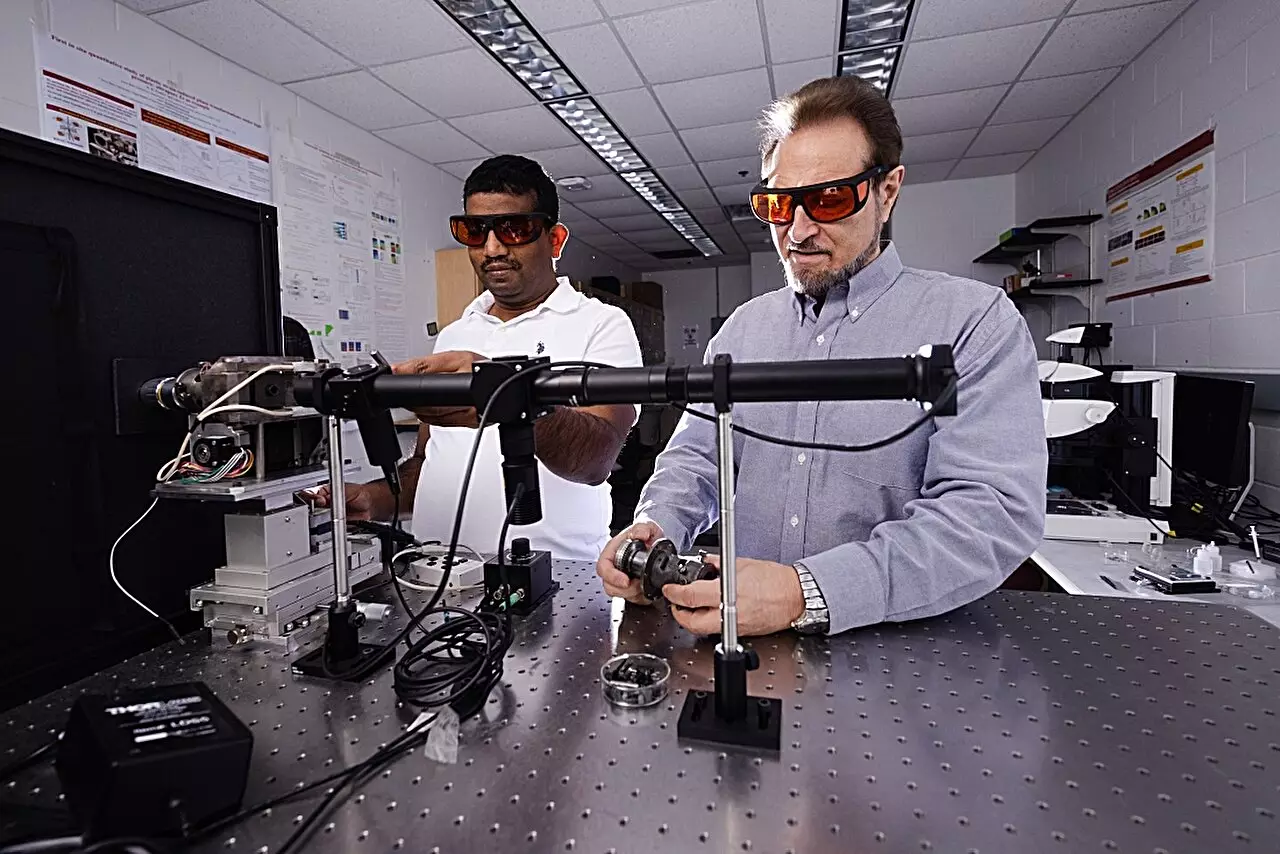

In 1999, Valery Levitas embarked on a significant journey when he relocated from Europe to the United States, bringing with him a sophisticated rotational diamond anvil cell. This piece of equipment has become pivotal for his research group at Iowa State University, allowing them to apply immense pressure and shear to various materials while closely observing their structural changes in real-time. The purpose of their investigations? To explore the intricate relationship between material deformation and the resulting properties, particularly for substances like silicon that are essential for electronics.

Levitas, who holds the prestigious title of Anson Marston Distinguished Professor of Engineering, emphasizes the interdisciplinary nature of this research. By merging concepts from advanced mechanics, physics, material science, and applied mathematics, his team aims to unravel the mysteries of phase transformations during material manipulation. These investigations hold great promise, not just for theoretical understanding but for potential practical applications.

One of Levitas’s most recent and significant findings revolves around silicon’s unusual behavior when subjected to both pressure and plastic shear deformation. The research was detailed in a publication in *Nature Communications*, with contributions from a talented team of postdoctoral researchers and collaborators from various institutions. Unlike past studies that primarily focused on silicon’s behavior under high pressure alone, Levitas’s team ventured into the interplay of pressure and shear, uncovering new transformations in silicon’s crystal structure that could pave the way for innovative uses of the material.

The team defined their experimental goals clearly: to observe how different particle sizes of silicon—ranging from one millionth of a meter to 100 billionths—respond to unique strains introduced by the diamond anvil cell. This groundbreaking approach has allowed them to identify plastic strain-induced phase transformations that differ markedly from previous observations.

A particularly striking outcome of their experiments showed that silicon can transition from its “Si-I” phase to the “Si-II” phase at dramatically lower pressures—only 0.3 gigapascals as opposed to the expected 16.2 gigapascals. This 54-fold reduction in pressure required for transformation represents a substantial leap forward in material science research. Levitas enthusiastically acknowledges the value of this breakthrough, citing its potential to revolutionize how industries utilize silicon under varying pressure conditions.

Furthermore, he underscores the importance of microstructure changes over mere alterations in size and shape. By manipulating the microstructural properties of silicon through physical strain, the team can induce transformations with new functional attributes that can be harnessed for real-world applications.

The relevance of Levitas’s findings extends beyond the academic sphere. As industries strive to develop more advanced electronic and optical materials, the ability to achieve desired properties at low pressures means that costs could be significantly reduced while enabling access to traditionally high-pressure materials. Levitas’s assertion—“Working with very high pressures for these phase transformations isn’t practical for industry”—highlights the essential nature of this research in addressing industrial challenges.

Moreover, the potential for creating nanocomposites with optimized physical and mechanical properties is an appealing prospect for manufacturers. The variability and refinement of these silicon phases could lead to enhanced functionality in products ranging from semiconductor devices to advanced optical systems.

Levitas’s anticipation of silicon’s responses to pressures was a product of two decades of theoretical groundwork and innovation. His team’s willingness to delve into the uncharted territories of material science has yielded insights that could fundamentally alter the landscape of how materials are understood and used. In an era marked by technological advancement, the integration of mechanical deformation techniques stands to not only broaden the horizons of material science but also to support industry in developing next-generation products. As this research continues to evolve, the journey of discovery led by Valery Levitas and his team promises to drive sustainable innovations in materials engineering for years to come.

Leave a Reply