Biological systems exhibit remarkable capabilities in developing structures that embody strength and flexibility. A prime example is the sea sponge, which achieves a sophisticated balance by layering materials with varied properties, resulting in a sophisticated, resilient architecture. Researchers like Nancy Sottos from the Beckman Institute for Advanced Science and Technology have noted the profound lessons that nature can teach us about material properties. Her statement resonates well in the scientific community: “Patterned materials often contain both stiff and soft regions, allowing them to withstand high strains without breaking while maintaining impressive strength.” This observation underscores the need for innovative designs in synthetic materials that mimic the intricacies found in biological organisms.

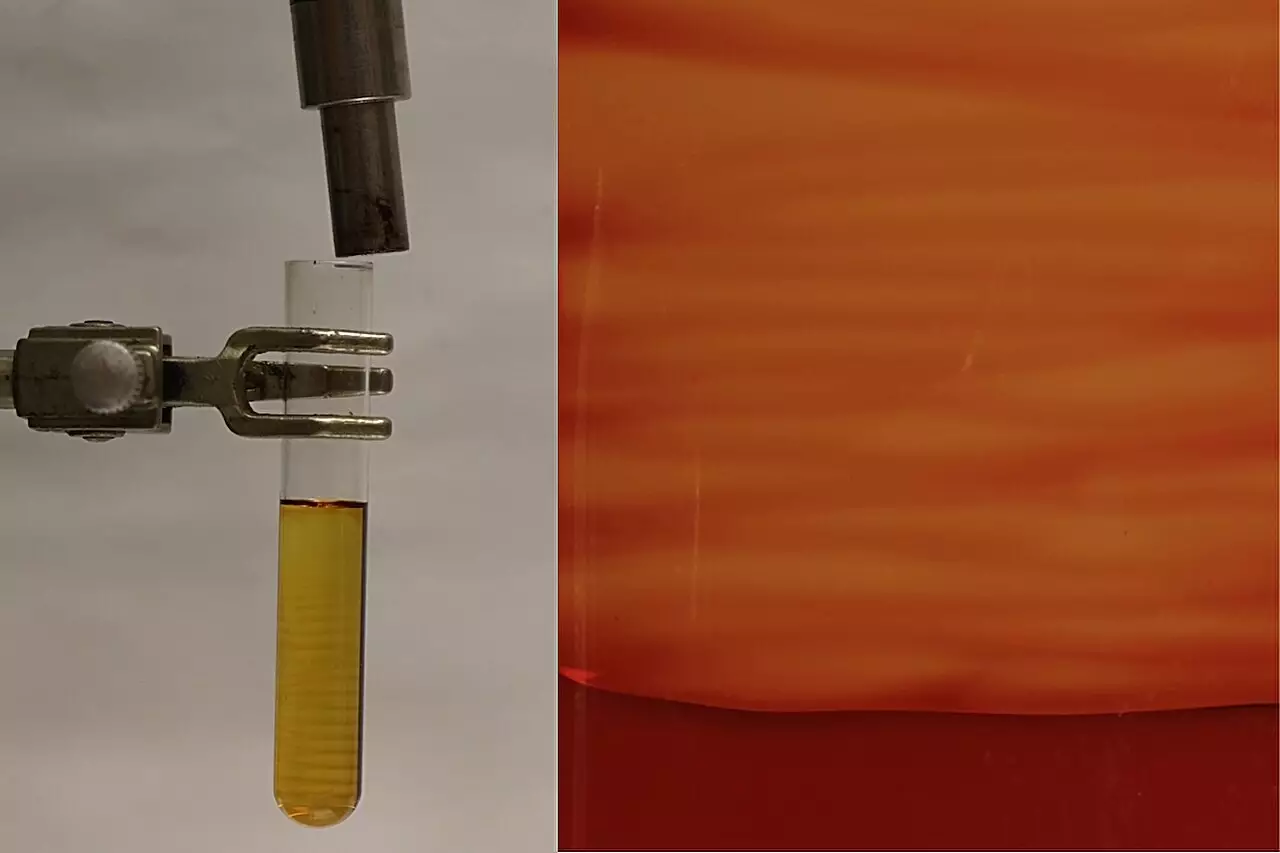

Recent advancements in material science are rooted in processes such as frontal polymerization, a technique whereby heat instigates a chemical reaction to produce polymers. This process gained recognition in 2021 when Sottos and her team emphasized its efficacy in manufacturing biologically inspired materials. Their current research, recently published in *Nature*, reveals a significant evolution in this technique: the ability to control the crystallization patterns within polymers. This controlled crystallization is pivotal in enhancing the toughness and durability of the materials produced, setting a promising new course for the industry.

Frontal polymerization diverges from traditional manufacturing methods, which often depend on molds and milling, creating opportunities for unique properties and structural advantages. Jeff Moore, a leading researcher in the team, noted that this approach opens doors to material innovation without the constraints of conventional production. The results demonstrate the potential of creating materials with unprecedented resilience through patterning methods, suggesting a turning point in the synthesis of advanced materials.

The success of this endeavor can largely be attributed to the diverse expertise wielded by the research team. The complexities of manipulating chemical reactions to define polymer morphology demanded collaboration across multiple disciplines, including materials science, chemistry, and engineering. Justine Paul, the principal investigator, reflected on the challenges involved in optimizing reaction conditions, which underscored the importance of interdisciplinary partnerships throughout the research process. This synergistic approach allowed for the development of a polymer exhibiting both amorphous and crystalline characteristics, providing a versatile solution for various applications.

Moreover, Cecilia Leal’s contribution highlights the critical role of advanced analytical techniques, such as X-ray scattering, in understanding the orientation of polymer chains. This method illuminated the structural properties of the resultant materials, facilitating a deeper comprehension of the intricate relationship between composition and performance. Recognizing these molecular relationships drives the field forward, providing a scientific foundation for novel material design.

Alongside experimental efforts, modeling techniques emerge as essential tools in predicting and analyzing the impacts of thermo-chemical instabilities during the manufacturing process. Philippe Geubelle’s work in this area emphasizes the necessity of understanding the operational dynamics behind the creation of heterogeneous materials. His focus on the modeling aspects has been critical in unraveling the complexities that underlie the innovative methods being employed, thus reinforcing the need for a comprehensive understanding of material behavior during synthesis.

The collaboration between experimentalists and theorists at the Beckman Institute exemplifies how integrated efforts can lead to groundbreaking discoveries. The interaction between different fields enables researchers to explore a range of ideas while ensuring that developments are grounded in empirical evidence.

The strides made in developing patterned synthetic materials reflect a significant intersection of science, engineering, and nature. As researchers like Sottos, Moore, Leal, and Geubelle work collaboratively, their findings illuminate a promising future for advanced material design that closely parallels natural systems. Emphasizing resilience through innovative manufacturing techniques not only broadens the horizon for material applications but also encourages ongoing interdisciplinary dialogue to foster even greater discoveries. This framework not only enhances the durability and performance of synthetic materials but also highlights the invaluable lessons that nature offers in the quest for innovation.

Leave a Reply