Crystalline materials play a crucial role in various industries such as semiconductors, pharmaceuticals, photovoltaics, and catalysts. To fully harness the potential of these materials, it is essential to accurately identify their structures. Currently, powder X-ray diffraction is the widely used method for identifying crystalline materials. However, when dealing with complex multiphase samples containing different types of crystals, the identification process becomes a challenge. To overcome this hurdle, researchers have developed a new machine learning model that can identify the presence of icosahedral quasicrystal (i-QC) phases from multiphase powder X-ray diffraction patterns.

The accurate identification of crystalline materials is crucial in achieving desired properties and functionalities. This is particularly important in emerging fields such as energy storage, carbon capture, and advanced electronics. However, the identification process becomes time-consuming and complex when dealing with multiphase samples containing different phases with distinct structures, orientations, or compositions. Currently, scientists rely on their expertise to accurately identify the various phases present in the sample. This manual process can be prone to errors and delays. Therefore, there is a need for innovative methods that can expedite the identification process.

Machine learning has emerged as a powerful tool in various scientific fields, including materials science. By leveraging the power of data-driven methods, machine learning algorithms can learn patterns and make predictions based on the existing data. In the context of identifying crystalline materials, machine learning has shown promise in distinguishing individual phases within multiphase samples. However, the identification of unknown phases in multiphase samples remains a challenge.

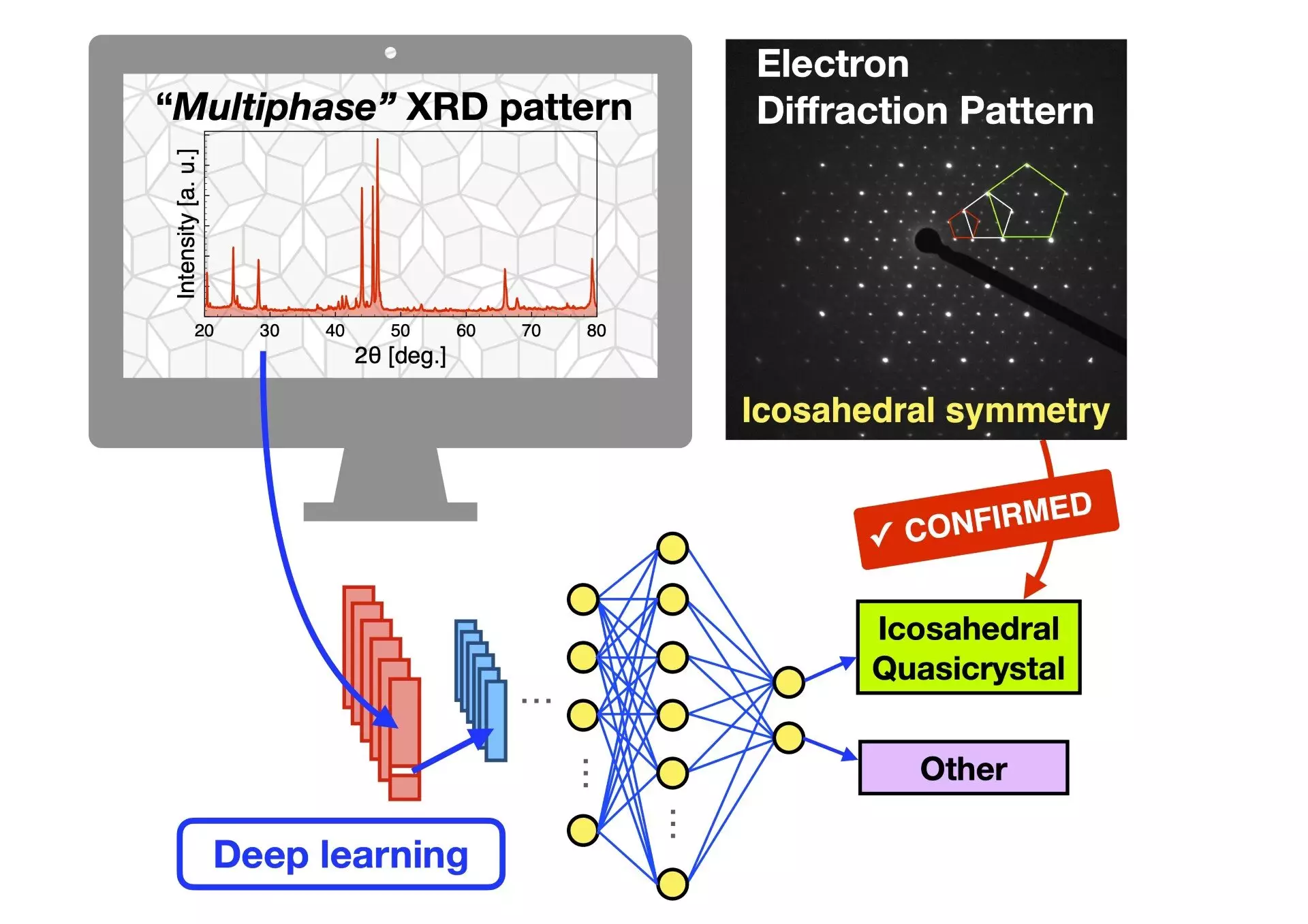

To address the challenge of identifying unknown phases, researchers from Tokyo University of Science (TUS) developed a new machine learning “binary classifier” model. The model was created using 80 types of convolutional neural networks and trained using synthetic multiphase X-ray diffraction patterns. These synthetic patterns represented the expected patterns associated with i-QC phases. The performance of the model was then assessed using both synthetic patterns and a database of actual patterns.

The results of the study were impressive. The model achieved a prediction accuracy of over 92%. It successfully identified an unknown i-QC phase within multiphase alloys, even when it was not the most prominent component in the mixture. This ability to detect unknown phases with high accuracy is a significant breakthrough in the field of materials science.

The proposed deep learning model not only identifies i-QC phases but also has the potential to identify new decagonal and dodecagonal quasicrystals. This opens up possibilities for the identification of unknown phases in various types of crystalline materials. The researchers are confident that this model will lead to accelerated phase identification of multiphase samples.

The development of a machine learning “binary classifier” model for identifying unknown phases in crystalline materials is a significant breakthrough. This model has the potential to revolutionize the field of materials science by expediting the identification process and enabling the discovery of new phases. With further advancements in machine learning and data-driven methods, the possibilities for identifying and understanding novel crystalline materials are immense. This study represents a crucial step forward towards unlocking the full potential of crystalline materials in various industrial applications.

Leave a Reply