Hydrogen fuel cells have emerged as a promising solution to address environmental challenges. However, the inconsistent operation of fuel cells due to the expansion and contraction of the polymer electrolyte membrane has been a significant hurdle. Over time, these deformations lead to cracks in the membrane, accelerating the undesired transport of hydrogen and causing operational failure. While various methods have been employed to tackle this issue, none have been able to fully prevent the formation and propagation of cracks.

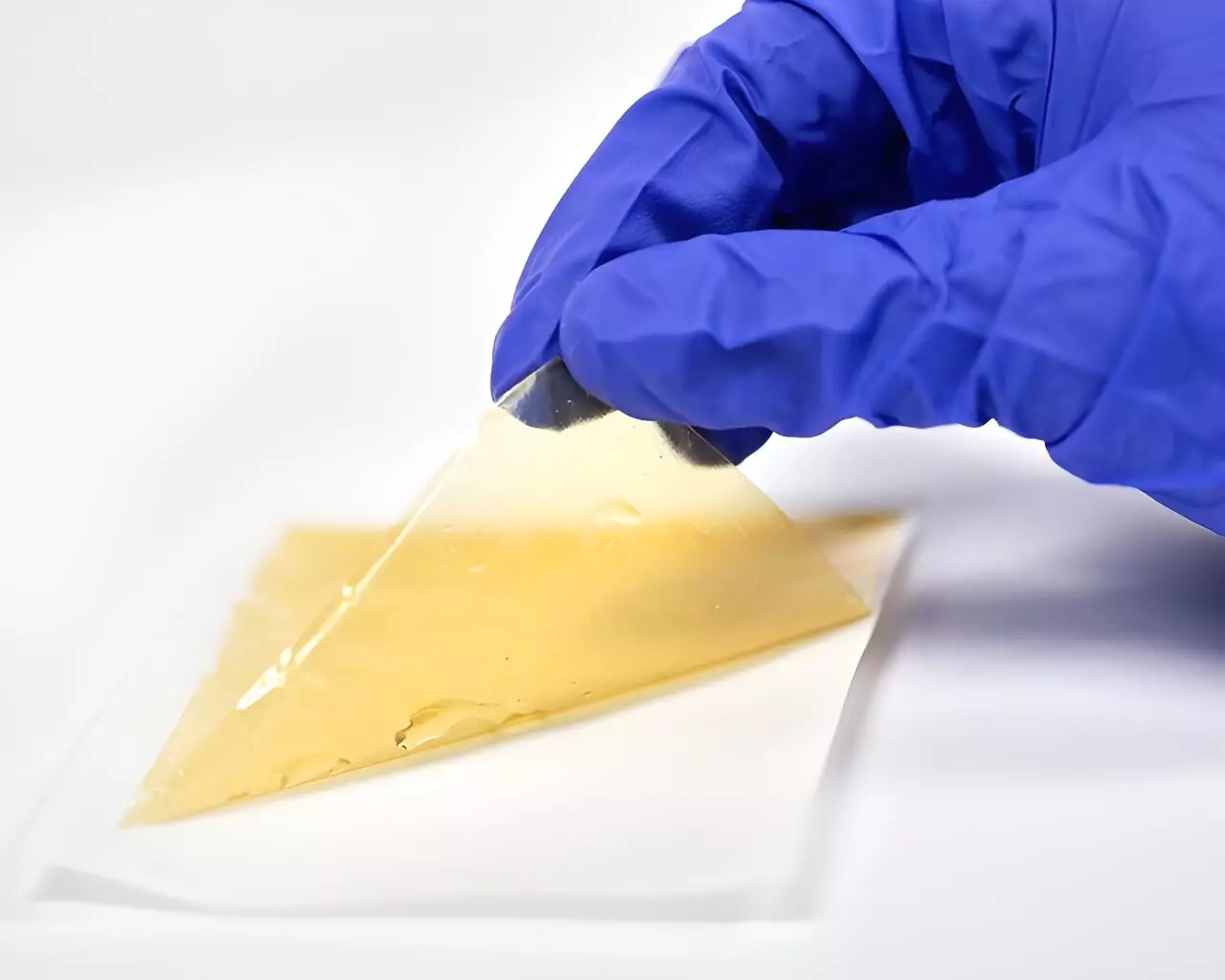

In a recent study published in the journal Advanced Materials, a team of researchers led by Associate Professor Sang Moon Kim from Incheon National University and Professor Zhigang Suo from Harvard University have developed a novel polymer electrolyte membrane that exhibits resistance to fatigue. The researchers utilized an interpenetrating network of Nafion and perfluoropolyether (PFPE) to create a category of fatigue-resistant electrolyte membranes.

The Functionality of the Membrane

Nafion, a commonly used plastic electrolyte, possesses proton-conducting properties, while PFPE contributes to the creation of a durable, rubbery polymer network. Through the incorporation of PFPE, the researchers slightly compromised electrochemical performance. However, this trade-off was outweighed by the remarkable enhancement in fatigue threshold and overall lifespan of the fuel cell. Among the various compositions of PFPE, the membrane with 50% saturation displayed promising electrochemical performance.

The Benefits: Enhanced Fatigue Resistance and Extended Lifespan

Compared to the original Nafion membrane, the Nafion-PFPE composite membrane exhibited significant improvements. The fatigue threshold was elevated by an impressive 175% and the lifespan of the fuel cell was extended by 1.7 times. The unmodified Nafion membrane had a lifespan of 242 hours, while the composite membrane lasted for 410 hours. These results demonstrate that while the addition of the rubbery network modestly reduces electrochemical performance, it dramatically improves fatigue resistance and overall longevity.

This groundbreaking study has far-reaching implications across various industries. The introduction of a fuel cell system with enhanced stability, durability, and performance opens doors to innovation in diverse fields. Beyond the realm of fuel cell vehicles, this advancement can impact the development of advanced technologies in drones, personal air vehicles, backup power sources, forklifts, bicycles, and scooters. Additionally, the strategy for enhancing fatigue resistance can be extended beyond fuel cells and applied to ion filters, battery separators, and actuation systems. This paves the way for high-durability, long-life desalination filters, flow battery separators, lithium metal battery separators, and artificial muscles.

The development of fatigue-resistant electrolyte membranes marks a revolutionary breakthrough in the field of hydrogen fuel cells. With this innovation, the long-term stable operation of fuel cells can become a reality. The work of Professor Sang Moon Kim, Professor Zhigang Suo, and their team brings us one step closer to realizing a sustainable and eco-friendly future. As further research and advancements are made in this area, the potential for fuel cells to transform multiple industries and drive environmental progress becomes increasingly promising.

The development and commercialization of fatigue-resistant electrolyte membranes present an exciting opportunity to overcome the challenges associated with fuel cell operation. The incorporation of an interpenetrating network of Nafion and PFPE opens doors to various applications, including fuel cell vehicles and other advanced technologies. This breakthrough has the potential to revolutionize industries and contribute to a greener future.

Leave a Reply