Programmable photonic integrated circuits (PPICs) have the potential to revolutionize computation, sensing, and signaling. Researchers at the Daegu Gyeongbuk Institute of Science and Technology (DGIST) in South Korea, along with their collaborators at the Korea Advanced Institute of Science and Technology (KAIST), have made significant progress in incorporating microelectromechanical systems (MEMS) into PPICs. This breakthrough, which has been published in the journal Nature Photonics, holds great promise for faster and more efficient computing, as well as advancements in artificial intelligence, neural networks, quantum computing, and communications.

One of the key achievements of the DGIST team is the integration of silicon-based photonic MEMS technologies onto PPIC chips that operate with extremely low power requirements. This innovation has resulted in a dramatic reduction in power consumption to femtowatt levels, which is over a million times better than the previous state of the art. Additionally, the technology allows for the development of PPICs that are up to five times smaller than existing options. These advancements not only contribute to energy efficiency but also enable the miniaturization of PPICs, making them more versatile and applicable in various domains.

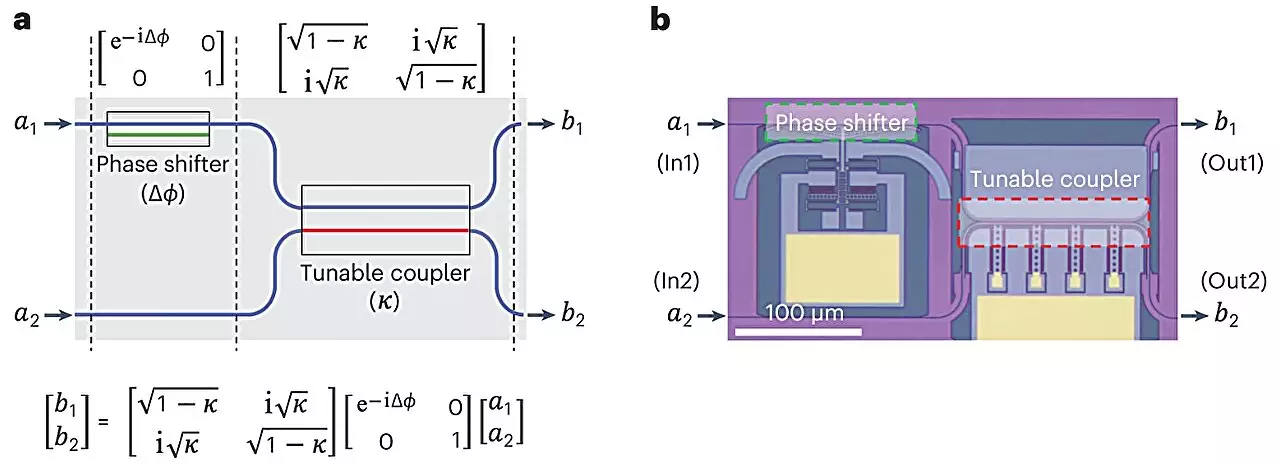

The usage of microelectromechanical systems within PPICs enables the interconversion of optical, electronic, and mechanical changes to perform necessary functions within an integrated circuit. By manipulating the “phase” of light waves and controlling the coupling between parallel waveguides, the DGIST team has fulfilled the fundamental requirements for building PPICs. These features, combined with micromechanical actuators, contribute to the creation of programmable integrated circuits. The use of electrostatic forces, such as the attractions and repulsions between fluctuating electric charges, powers the required tiny mechanical movements.

The success of the DGIST team lies in their innovative approach to fabricating the necessary silicon-based parts. By moving away from the temperature-dependent thermo-optic systems commonly employed, they have achieved significant reductions in power requirements. Moreover, the manufacturing process used in their research is compatible with conventional silicon wafer technology, allowing for large-scale production of photonic chips. This compatibility is crucial for the commercial applications of PPICs and paves the way for their widespread adoption in various technological domains.

The researchers envision this technology being refined and commercialized to create photonic computers that surpass conventional electronic computers in numerous applications. One such application is in the field of artificial intelligence, particularly in inference tasks. Additionally, the advancements in PPICs can contribute to advanced image processing and high-bandwidth data transmission. By continuously pushing the boundaries of computational technology, the DGIST team aims to further the field of photonics and its practical applications in modern technology.

The integration of microelectromechanical systems into programmable photonic integrated circuits represents a significant advancement in the field. The achievement of low power consumption, size reduction, and compatibility with conventional fabrication processes opens up new possibilities for faster and more efficient computing. Furthermore, the potential applications in artificial intelligence, image processing, and data transmission demonstrate the immense opportunities created by this research. As the DGIST team continues to refine their technology, the future of programmable photonic integrated circuits looks highly promising.

Leave a Reply