In today’s world, waste management has become a significant concern, with millions of tons of waste being generated by humans each year. Unfortunately, a large portion of this waste consists of non-degradable plastic and petroleum-based materials that end up in landfills. As a result, scientists have been exploring alternative materials that are both effective and environmentally friendly. One such material that has gained attention is mycelial fibers derived from mushroom bodies. These fibers offer promising potential for a wide range of consumer and industrial applications, including packaging, soundproofing, and textiles.

While mycelial fibers show great promise, conventional extraction methods have often resulted in unwanted coloration and the destruction of their intricate mycelial structures. This limitation has restricted their use at the nanoscale level and hindered their application in various industries.

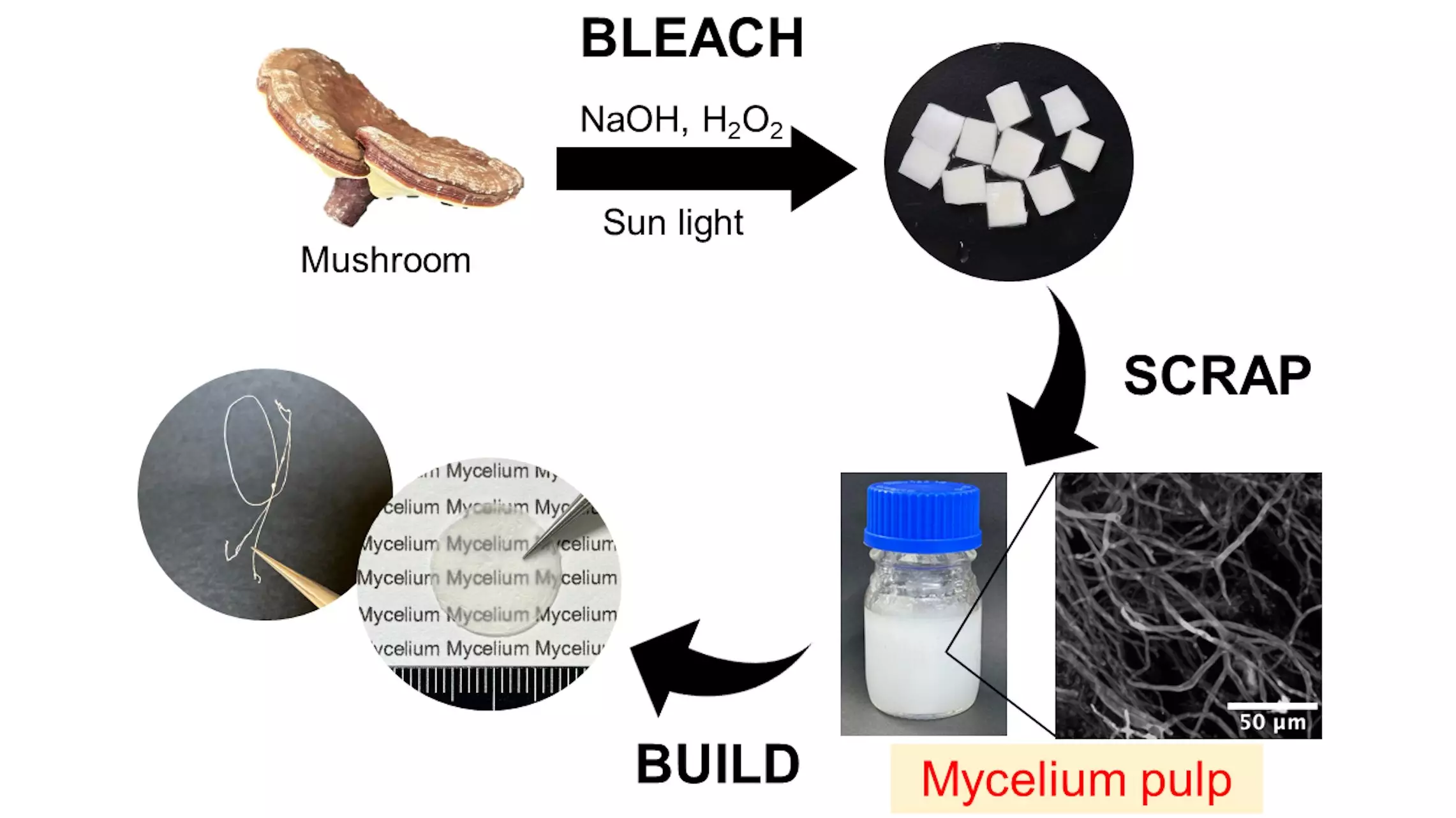

A recent study published in ACS Sustainable Chemistry & Engineering introduces a groundbreaking method of extracting mycelial pulp and fibers from mushrooms without damaging their structure. Led by Assistant Professor Satomi Tagawa from Shinshu University, the research team successfully treated enoki and reishi mushrooms with sodium hydroxide and hydrogen peroxide. They then bleached the obtained substances using sunlight, resulting in a white material. Ultrasonic treatment was applied to defibrillate the pulp at a mycelial level, producing a dispersion containing micrometer-sized mycelium fibers with intact structures.

The mycelial fibers obtained through this innovative process demonstrate excellent deformability, making them suitable for the design and manufacturing of products such as 3D porous sponges, 2D films, and 1D yarns. Moreover, this approach represents a valuable addition to the scrap-and-build approach for fabricating mushroom materials, supplementing existing bottom-up methods.

By developing a simple and efficient extraction method, this research opens up possibilities for upcycling by-products generated by the mushroom industry. This not only contributes to waste reduction but also promotes circularity and facilitates the reuse of mushroom materials. Furthermore, the study suggests that further research on sustainable materials and methods has the potential to create new industries, generate employment opportunities, and revitalize local communities.

The innovative approach to obtaining mycelial fibers from mushroom bodies represents a significant step towards sustainable material development. By preserving the intricate mycelial structures, this method expands the potential applications of mushroom-based materials in various industries. With further advancements and research in this field, we can expect to see an increase in the use of mycelial fibers as a viable and environmentally friendly alternative to traditional materials.

Leave a Reply