In the search for sustainable alternatives to petroleum-based plastics, researchers from North Carolina State University have made significant strides in developing biopolymer composite films using materials derived from crustaceans and seaweed. This innovative approach combines chitosan, derived from crab shells, and agarose, extracted from seaweed, to create films with enhanced properties. Not only are these films biodegradable, but they also possess antibacterial properties, repel water, and maintain transparency. This breakthrough has the potential to revolutionize the packaging industry by providing eco-friendly alternatives for food and consumer goods.

The research, led by Orlin Velev, a distinguished professor of Chemical and Biomolecular Engineering at NC State, aims to find sustainable replacements for synthetic polymers. While synthetic polymers are known for their film-forming capabilities, the goal is to replicate these properties using natural biopolymers. The challenge lies in adjusting the joint structure of these natural polymers, such as chitosan and agarose, to achieve the desired characteristics of synthetic polymers within a sustainable and biodegradable film.

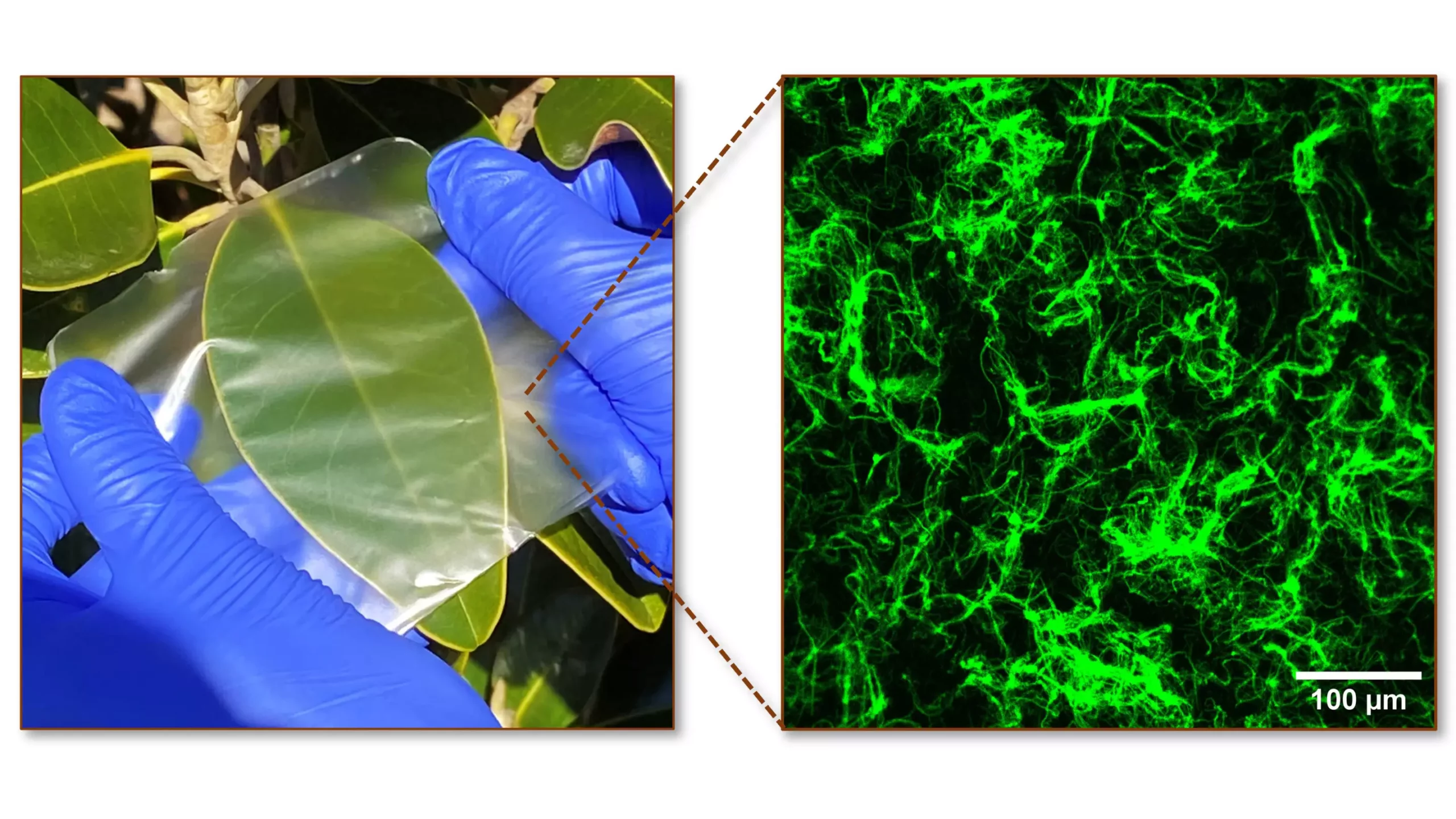

Instead of simply mixing chitosan and agarose together, Velev and his team took a different approach. They reinforced the agarose films with fibrillated colloidal scale material called “soft dendritic colloids,” made from chitosan. The hierarchical branching of the chitosan micro- and nanoscale fibrils provides strength and stability to the agarose film where they are embedded. This technique allows for the modification of natural polymers without chemical alteration, resulting in improved mechanical properties and resistance to water.

The research findings demonstrate that the biopolymer composites are approximately four times stronger than agarose films alone. Additionally, these films exhibit resistance to E.coli, a commonly studied bacterium. The compatibility of chitosan particles with agarose matrix, along with their opposite charge, results in neutralized charges when mixed. This charge neutralization enhances the materials’ resistance to water.

The biopolymer composite films show promising biodegradable properties. While initially displaying strong antibacterial characteristics, the films eventually degrade as they are made from natural materials. After a month underground, the composite films degrade readily, providing an advantage over common plastic films that remain intact for the same period. This biodegradability makes these films an ideal candidate for sustainable packaging solutions.

Looking ahead, Velev emphasizes the need to continue improving the structure of biopolymer composite films. The ultimate goal is to match the properties of synthetic polymer films, including impermeability to oxygen and water. The research team aims to develop films that are both biodegradable and resistant to water and oxygen permeation. Furthermore, enhancing the scalability of the production process is a crucial aspect. By exploring continuous processes similar to papermaking, the team hopes to increase the efficiency of manufacturing these sustainable films in larger quantities.

The advancements in creating biopolymer composite films from crustaceans and seaweed offer a promising sustainable alternative to petroleum-based plastic films. The combination of chitosan and agarose results in films with enhanced strength, antibacterial properties, water repellency, and biodegradability. These findings pave the way for the development of eco-friendly packaging films for various applications. While challenges remain in replicating the properties of synthetic polymer films and increasing scalability, the research signifies a significant step towards a greener future in the packaging industry.

Leave a Reply