The building envelope is a critical part of any building structure, as it provides protection against external environmental factors such as sun, rain, snow, wind, and pollution. This multilayer passive element plays a crucial role in maintaining the health, comfort, and energy efficiency of the building and its occupants. However, issues such as air leakage, heat transfer, and moisture diffusion can have a significant impact on the performance of the building envelope. Moisture penetration, for example, can lead to mold growth, insulation inefficiency, and the deterioration of envelope materials.

In the construction industry, various barrier membranes, including plastic sheeting and rigid foam insulation, are commonly used in building envelopes. However, the excessive use of traditional materials such as polyethylene extruded sheets can harm the environment. To address this concern, researchers have been exploring the use of biopolymers in building envelope materials.

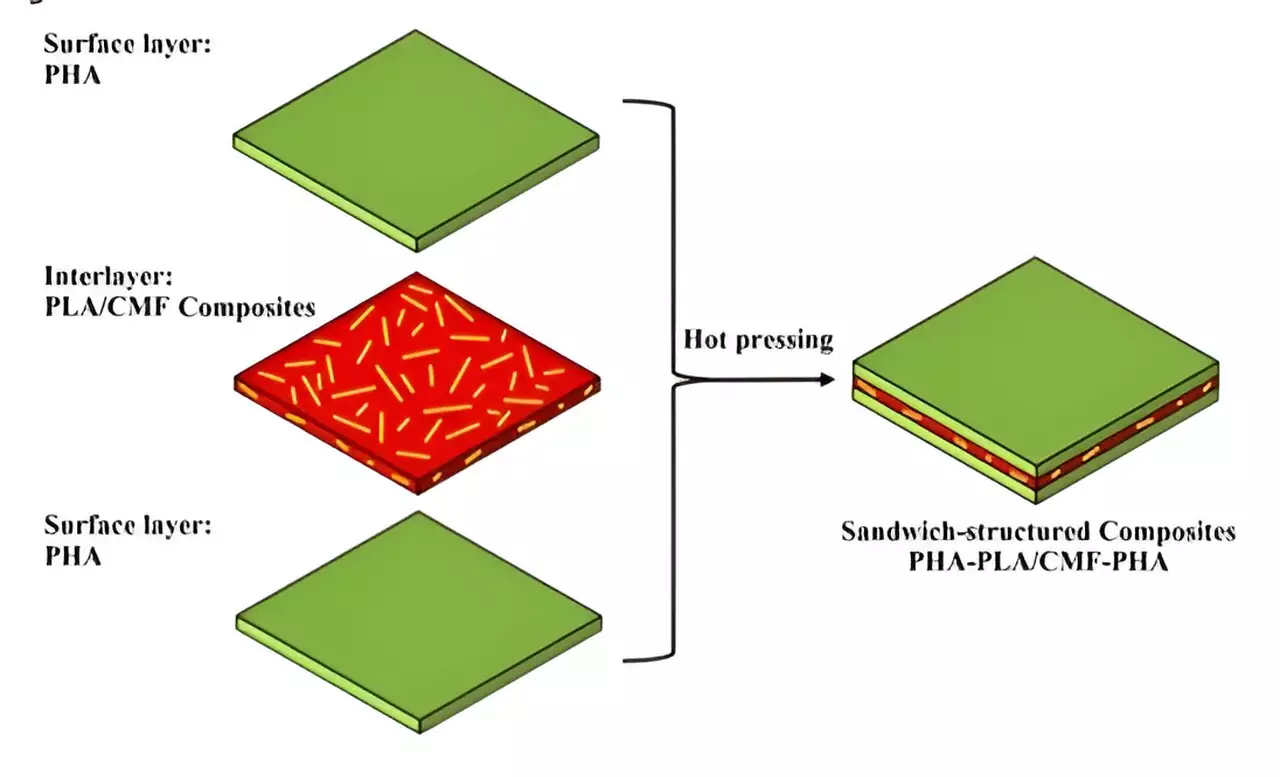

Researchers at Laval University in Canada, led by Masoud Dadras Chomachayi, have developed a new sandwich-structured composite for building envelopes using biobased materials. This composite consists of surface layers of polyhydroxyalkanoate (PHA), an excellent vapor barrier material, an interlayer of polylactic acid, and cellulose microfibers for environmental and economic benefits.

To improve the compatibility between natural reinforcement (cellulose microfibers) and the polymer matrix, the researchers chemically modified the cellulose microfibers using a sol-gel process. This modification resulted in highly hydrophobic cellulose microfibers that exhibited uniform dispersion in the polylactic acid matrix. The modified cellulose microfibers showed superior performance compared to untreated cellulose microfibers in terms of water vapor permeability, making them ideal for building envelope applications.

The researchers conducted thermogravimetric analyses to assess the thermal stability of the sandwich composites. The results showed improved thermal stability compared to traditional materials. Additionally, by incorporating the modified cellulose microfibers, the tensile modulus and strength of the composites were enhanced, further improving their mechanical properties.

The researchers thoroughly characterized the prepared sandwich composites by examining their surface morphology, thermal stability, mechanical properties, and vapor barrier performance. The cellulose microfibers were examined before and after the sol-gel modification process using scanning electron microscopy. Fourier transform infrared analysis was used to analyze the chemical structure of the cellulose microfibers.

To ensure the long-term durability of the building envelope materials, the researchers subjected them to a durability test, simulating accelerated aging. This test allowed them to assess the effect of aging on the mechanical and barrier properties of the composite materials.

The sandwich-structured composite developed by Chomachayi and his team offers several advantages for building envelope applications. The use of biopolymers, such as polyhydroxyalkanoate and polylactic acid, reduces reliance on petroleum-based materials and promotes environmental sustainability. The modified cellulose microfibers, with their enhanced hydrophobicity and thermal stability, contribute to the overall performance and longevity of the composite. The successful outcomes of this study demonstrate the potential of biopolymers as alternatives to traditional materials in construction applications.

Further research aims to enhance the flexibility of the sandwich-structured composite for wider and more diverse construction applications. The ongoing exploration of biopolymers and renewable materials in building envelope design holds promise for improving energy efficiency, reducing environmental impacts, and ensuring the long-term durability and performance of buildings.

The development of a new sandwich-structured composite using biobased materials offers an innovative solution for improving building envelopes. The combination of polyhydroxyalkanoate, polylactic acid, and modified cellulose microfibers provides enhanced vapor barrier properties, mechanical strength, and thermal stability. This research demonstrates the potential of biopolymers as sustainable alternatives in construction materials and paves the way for further advancements in building envelope technology.

Leave a Reply