Recent advancements in the field of soft robotics have introduced the potential for fabric-based soft pneumatic actuators (FSPAs) to revolutionize industries ranging from medical technology to adaptive structures. Foundational to these innovations is a new study published in Scientific Reports, which reveals a method for designing FSPAs that incorporates Turing patterns. These models act as flexible, adaptable devices that respond to pneumatic pressure, allowing for a remarkable array of movements and deformations that traditional rigid parts cannot achieve. The discussion surrounding FSPAs is pivotal in understanding not only the mechanics of soft robotics but also the implications for human safety and efficient interactions with delicate environments.

The mechanics of FSPAs operate through inflation and deflation, enabling the fabric to twist, stretch, and bend in response to pressure stimuli. Such movements foster a more human-friendly robotic interface. The significance of the study lies in its utilization of Turing patterns, derived from Alan Turing’s morphogenesis theory established in 1952, which explains how complex patterns emerge in natural systems from simple interactions between substances. This theoretical framework illustrates how reaction-diffusion systems can produce stable, repetitive patterns, essential for designing fabric structures that deform predictably when actuated by pressure.

One of the revolutionary aspects of the study is the exploration of anisotropic materials, where properties are directionally dependent, diverging from the isotropic materials typically employed in traditional actuator designs. The incorporation of Turing patterns into the surface texture of FSPAs aims to streamline the trial-and-error process that has historically plagued actuator development, addressing a significant barrier in soft robotics.

Led by a collaborative team of researchers from distinct Toyota branches, the study emphasizes the need for an automation-driven approach to FSPA design. Dr. Masato Tanaka and Dr. Tsuyoshi Nomura, along with Dr. Yuyang Song, advocate for the optimization of material orientations via advanced design methodologies. Specifically, they deploy gradient-based orientation optimization to ascertain how the fibers in the fabric should be distributed across the actuator surface.

Utilizing the nonlinear finite element method, the researchers fine-tuned the orientation of the material, converting theoretical models of anisotropic reaction-diffusion systems into tangible fabric patterns. The critical outcome of this design process is that it allows for a precise deformation of the actuator surface, transforming the way these devices would react under pressure.

This methodological advancement not only enhances the actuator’s performance but also reflects progress towards scalable fabrication techniques that can address industry needs more efficiently.

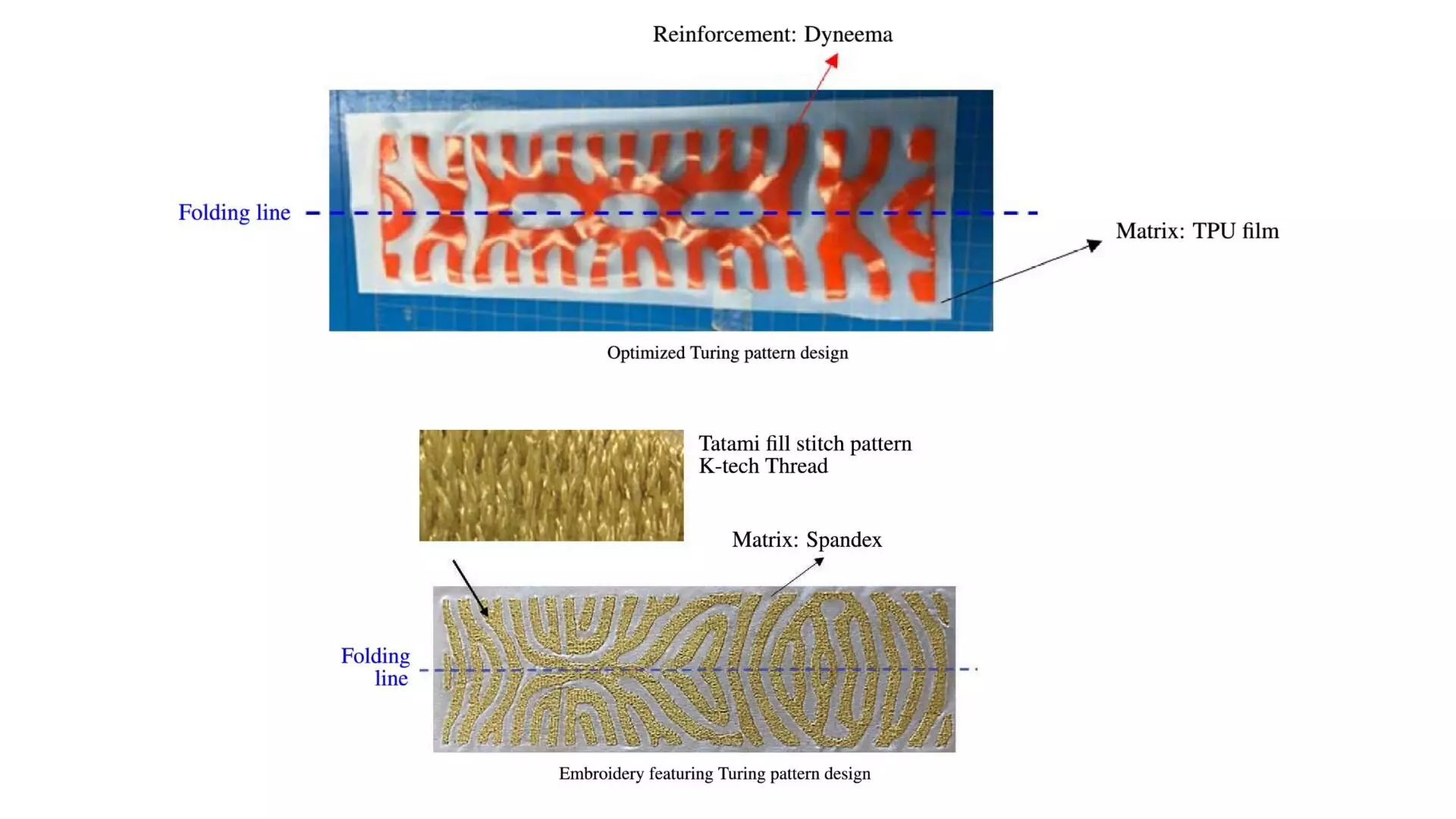

Upon finalizing the design, the research team employed two primary fabrication techniques: heat bonding and embroidery. In heat bonding, materials such as Dyneema are laser-cut into specific Turing patterns and adhered to softer films like TPU using heat, forming a hybrid structure that exhibits controlled movement. Conversely, the embroidery method integrates the patterns directly into soft fabrics using stiffer threads, creating variable stiffness regions that aid in producing complex movements.

The advantages of both techniques lay in their scalability and cost-effectiveness, promising a pathway for mass production of FSPAs with varied applications. The researchers found that Turing pattern designs significantly outperformed classical designs in certain scenarios, demonstrating a 10% efficiency increase in C-shaped movements and showcasing equal competency for twisting motions.

Looking forward, the research team anticipates further exploration into enhancing actuator performance by integrating Turing pattern designs with novel materials like shape memory alloys and electroactive polymers. Such innovations could lead to the development of FSPAs that possess superior dynamic responses to a variety of stimuli. Additionally, scaling fabrication techniques to facilitate mass production and larger actuator dimensions remains an intriguing area for future research.

The potential applications for these advanced structures are extensive, spanning medical devices, robotic grippers, and assistive technologies, all of which can greatly benefit from the unique properties FSPAs can offer. By fostering collaborations that merge theoretical research with practical applications, we stand on the brink of achieving remarkable improvements in how soft robotics will function and interact in real-world environments.

The study successfully aligns Turing pattern methodology with the design and production of FSPAs, setting the stage for future innovations that could redefine the landscape of soft robotics.

Leave a Reply