Recent advancements in structural engineering have further illuminated the complex behavior of ultra-high-performance concrete (UHPC) when it is subjected to confinement by fiber-reinforced polymers (FRP). Conducted by an impressive team of researchers led by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie, the study published in the journal Engineering presents a groundbreaking analysis-oriented stress-strain model. This meticulous research not only fosters a deeper comprehension of UHPC’s compressive attributes but also addresses enduring challenges that have persistently puzzled engineering professionals.

UHPC, celebrated for its unparalleled strength and durability, has garnered significant attention in modern construction practices. However, the intricacies involved in manipulating its behavior when confined with FRP materials have introduced complications that traditional models often fail to resolve. While existing frameworks may effectively capture normal-strength concrete (NSC) under similar conditions, their inadequacies become glaringly apparent when extrapolated to UHPC scenarios.

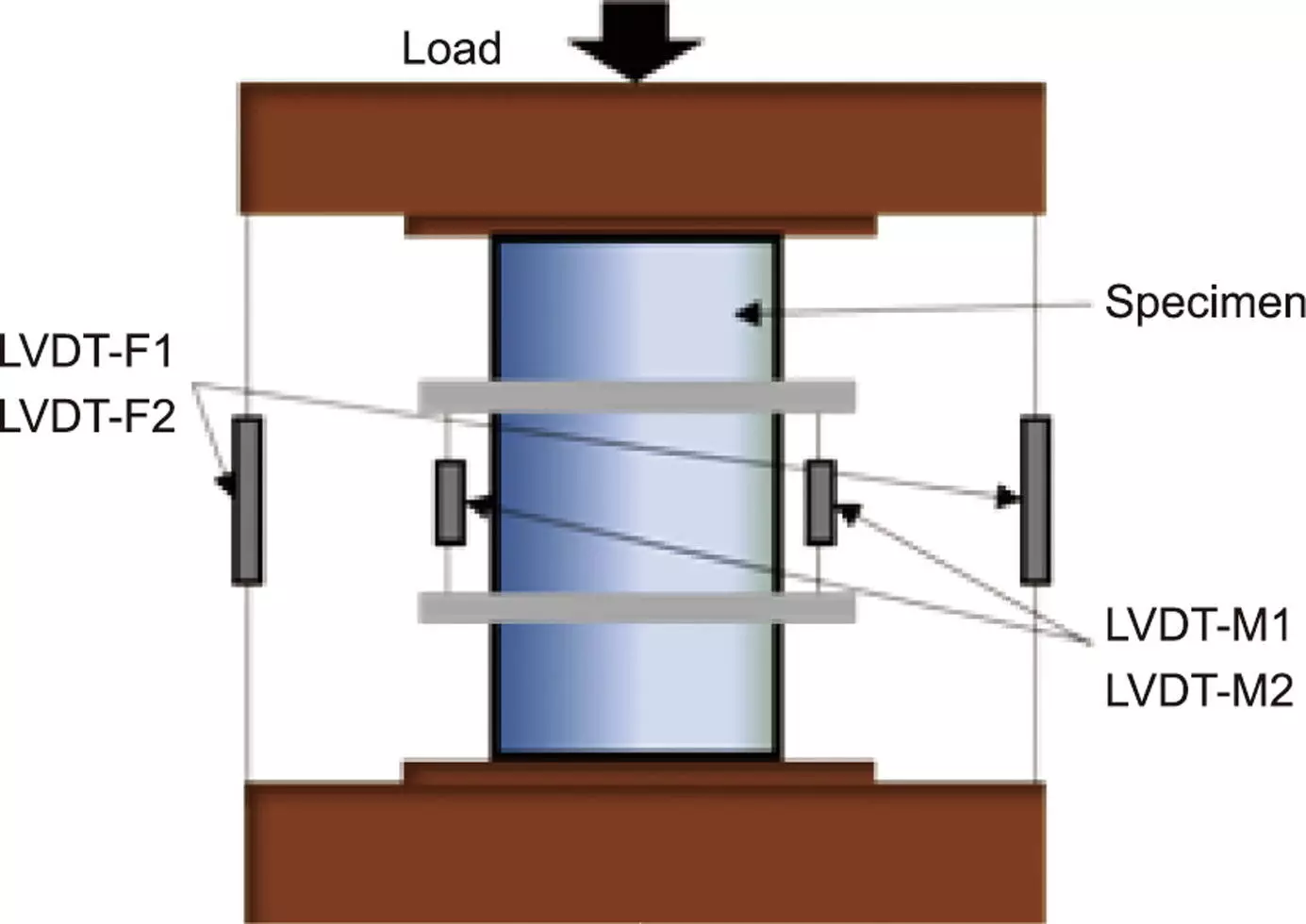

The collaborative efforts emanating from Huazhong University of Science and Technology and Southern University of Science and Technology have sought to fill the void left by conventional models. Central to their investigation was the examination of failure mechanisms in UHPC under concentric compression. By designing and conducting a comprehensive series of experiments, the researchers endeavored to reveal the fundamental behaviors of UHPC when confined by FRP.

One crucial finding identified that the stress-path-independency paradigm, which has widely been accepted in the context of FRP-confined NSC, does not apply effectively to UHPC. This observation necessitated a paradigm shift, compelling the researchers to rethink existing theories to accurately reflect the behaviors seen in higher-performing concrete types.

Among the revelations from this study was a key insight into the formation of major diagonal cracks in FRP-confined UHPC. This phenomenon presented a marked variation in lateral expansion, significantly affecting the effectiveness of the confining pressure exerted by FRPs. The drop in effective pressure presents critical implications for the traditional assumptions of stress-path-independency that has guided prior modeling efforts, thus challenging the status quo in concrete research.

To overcome these challenges, the research team introduced a fresh model that integrates stress-path dependency, modifying traditional approaches to accommodate the unique behaviors exhibited by UHPC. This new model not only adjusts the confining pressure but also introduces an additional equation designed to capture the dynamics of the confining pressure gap, thereby refining the analytical accuracy of their predictions.

The validation of this innovative model was achieved through a comprehensive examination of previously collected test results, ultimately demonstrating enhanced predictive capabilities of the UHPC’s stress-strain behavior. This enhancement is pivotal, as it affords engineers a more robust and credible tool for both the design and analysis of structures utilizing UHPC.

The ramifications of this novel approach extend deeply into the realm of structural engineering and concrete science. The introduction of an analysis-oriented model that accurately accounts for stress-path dependency significantly elevates the design and safety standards for structures incorporating UHPC technology. With its potential to reshape the methodologies employed within the construction industry, this research paves pathways for advanced engineering practices that prioritize both performance and sustainability.

As construction methodologies continue to evolve, the insights gleaned from this research herald a promising future for ultra-high-performance concrete applications. Not only does the new model offer practical solutions for enhancing the performance and longevity of UHPC structures, but it also invites further explorations into the realm of concrete technology and its applications.

For engineers and researchers engaged in the study and application of UHPC, the findings of this research yield not simply a theoretical advancement, but a transformative resource that could underpin future innovations. As the demand for safer, more efficient designs intensifies, this study serves as a vital contribution, steering the trajectory of concrete applications towards heightened performance and durability, thus shaping the future of the construction industry.

Leave a Reply