A groundbreaking discovery from the University of Toronto Engineering researchers has unveiled a newly designed catalyst capable of efficiently converting captured carbon into valuable products. This innovative catalyst showcases its effectiveness even in the presence of contaminants that typically degrade the performance of current catalyst versions. The findings of this research hold significant promise in advancing more economically favorable techniques for carbon capture and storage that can seamlessly integrate with existing industrial processes.

The importance of this new catalyst lies in addressing the challenges faced in decarbonizing industries like steel and cement manufacturing. Professor David Sinton, the senior author of the research paper published in Nature Energy, emphasizes the necessity of inventing cost-effective methods to capture and upgrade carbon in waste streams from such industries. The catalyst developed by Sinton and his team utilizes electrolyzers to convert CO2 and electricity into valuable products such as ethylene and ethanol, which can be utilized as fuels or as chemical feedstocks for various applications.

One of the key findings of the research is the impact of contaminants, such as sulfur oxides, on catalyst performance. Traditional catalysts are designed to operate with a pure CO2 feed, making them vulnerable to degradation when exposed to impurities. Sulfur oxides, in particular, bind to the catalyst surface, reducing the efficiency of the reaction and generating unwanted by-products. This challenge poses a significant hurdle in the efficient conversion of carbon from industrial waste streams.

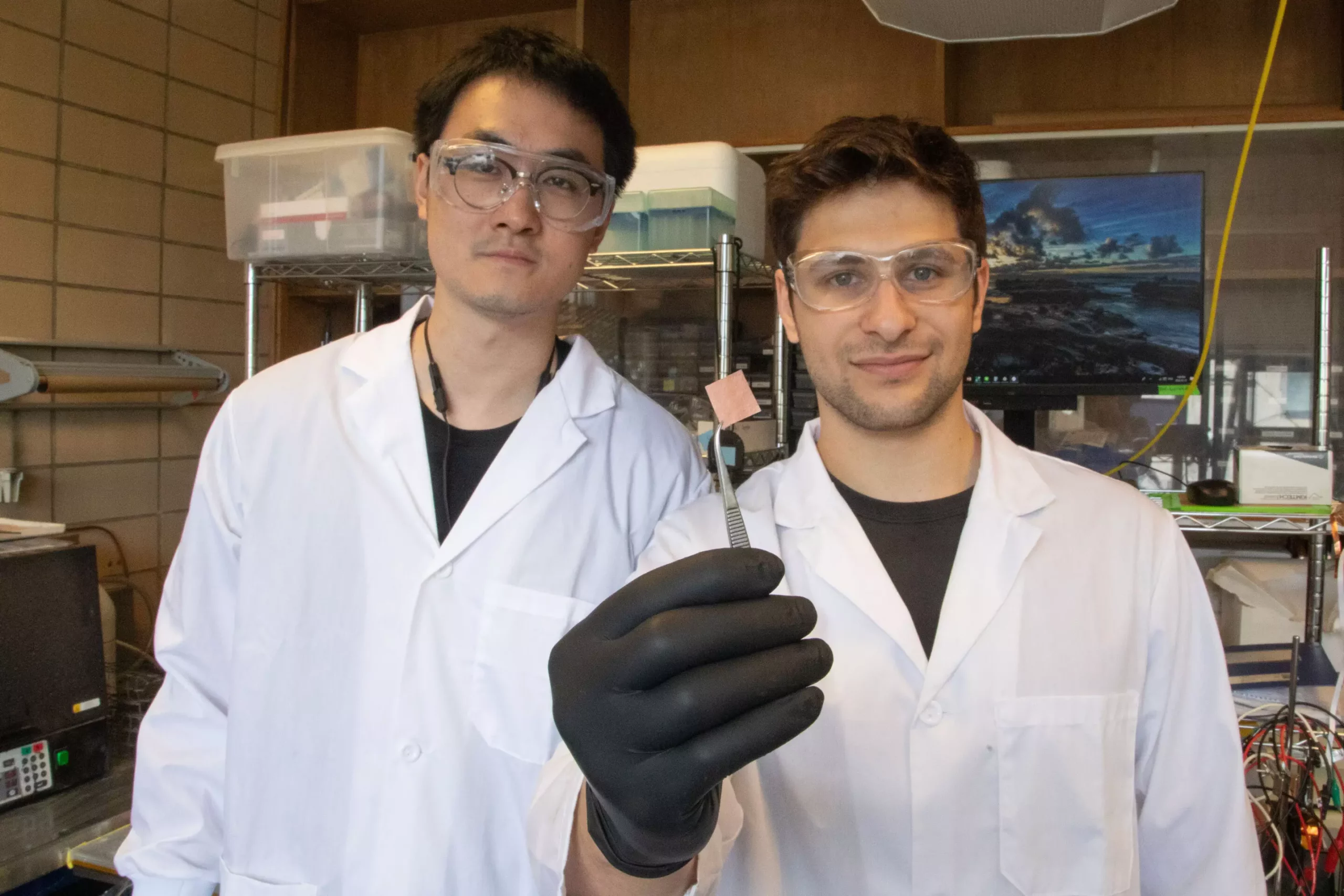

To overcome the issue of contaminant poisoning, the research team made significant modifications to a conventional copper-based catalyst. By incorporating a thin layer of polyteterafluoroethylene (Teflon) on one side and adding a layer of Nafion, an electrically-conductive polymer, on the other side, the catalyst exhibited resilience to sulfur oxide exposure. The Teflon layer altered the surface chemistry, hindering the reactions that lead to sulfur oxide poisoning, while the Nafion layer created a barrier that prevented sulfur oxides from reaching the catalyst surface.

The resilience of the new catalyst was put to the test by feeding it with a mix of CO2 and sulfur dioxide (SO2) at industrial waste stream concentrations. Despite the harsh conditions, the catalyst maintained a Faraday efficiency of 50% over 150 hours, showcasing its robust performance in the presence of contaminants. This level of efficiency, sustained over an extended period, demonstrates the viability of the new catalyst for practical applications in carbon conversion processes.

The successful development of a catalyst resistant to sulfur oxide poisoning opens up possibilities for addressing other chemical impurities in waste streams. While sulfur oxides present a significant challenge, the research team is now looking into tackling a broader range of contaminants, including nitrogen oxides and oxygen. The versatility of the approach employed in designing the new catalyst suggests that similar modifications could be applied to existing high-performing catalysts to enhance their resistance to impurities.

The research conducted by the University of Toronto Engineering team represents a significant breakthrough in the field of carbon conversion and catalyst design. By developing a resilient catalyst that can efficiently convert captured carbon into valuable products even in the presence of contaminants, the team has laid the foundation for more sustainable and economically feasible carbon capture and storage techniques. The implications of this research extend beyond sulfur oxide poisoning to other chemical impurities, paving the way for enhanced efficiency and viability in carbon upgrading processes.

Leave a Reply