In a world increasingly driven by environmental sustainability, innovations in battery technology have taken a pivotal role. A collaborative research team from POSTECH and Hansol Chemical has made strides to create a groundbreaking fluorine-free binder and electrolyte system, which promises to enhance the eco-friendliness and performance of batteries. Their research findings, which appear in the esteemed Chemical Engineering Journal, highlight a commitment to advancing battery technology in line with growing environmental concerns. This development is timely, especially as regulatory frameworks around hazardous substances tighten globally, particularly in the context of per- and polyfluoroalkyl substances (PFAS).

At present, traditional lithium-ion batteries are primarily built using fluorinated compounds such as polyvinylidene fluoride (PVDF) for binders and lithium hexafluorophosphate (LiPF6) for electrolyte salts. While these materials have served the industry for years, they come with significant drawbacks. The decomposition of these fluorinated compounds leads to the formation of hydrogen fluoride (HF), a highly toxic substance that can compromise both the safety and longevity of the battery. Further complicating matters, PVDF is notoriously non-biodegradable, raising concerns about long-term environmental impact. Given that the European Union is poised to impose stricter regulations on PFAS, including a potential ban by 2026, the urgency for alternative solutions has never been higher.

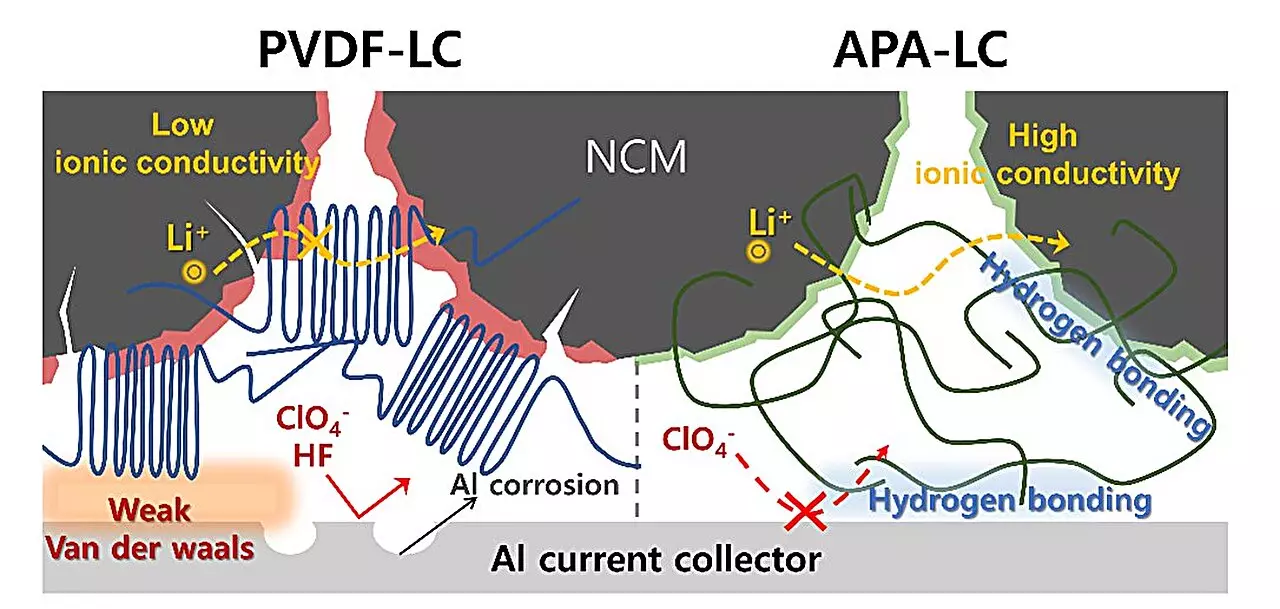

Responding to these challenges, the research team introduced the innovative non-fluorinated battery system, termed as the “APA-LC” system. This new system substitutes the harmful lithium hexafluorophosphate with lithium perchlorate (LiClO4), creating a safer electrolyte that meets emerging regulatory requirements. The adoption of a non-fluorinated aromatic polyamide (APA) binder not only complies with the expected environmental standards but also strengthens the performance of the battery. The APA binder effectively improves bonding between the cathode’s active materials and the aluminum current collector, which addresses issues related to corrosion in the electrolyte and results in a longer battery lifespan.

By incorporating lithium chloride (LiCl) and lithium oxide (Li2O) into the LC system, the researchers have significantly lowered the energy barrier at the ion migration interface. This technological leap enhances lithium ion diffusion, enabling exceptional output performance that surpasses traditional systems. The APA-LC system was not merely theoretical; it demonstrated impressive results during testing, showcasing a 20% improvement in capacity retention after 200 charge/discharge cycles, even under fast-charging regimes.

To validate their research, the team engineered a high-capacity pouch cell with a 1.5 Ah rate using their newly developed APA-LC system. The cell exhibited remarkable discharge capacity and maintained robust performance throughout rapid charging trials. This marks a significant milestone, being the world’s first fully scalable battery system developed entirely from non-fluorinated materials. It provides a promising glimpse into a future where safety and environmental responsibility are at the forefront of battery technology.

Professor Soojin Park, leading the research initiative, emphasized the importance of their findings, stating, “We haven’t just replaced fluorinated systems; we’ve proven high-capacity retention and outstanding stability.” This declaration underscores the potential for the industry to shift toward non-fluorinated components without compromising performance. Young-Ho Yoon, Managing Director of Hansol Chemical’s Secondary Battery Materials Business, highlighted the strategic implications of this advancement, indicating the potential to capture a share of the cathode binder market, projected to reach KRW 1.7 trillion by 2026.

The research conducted by POSTECH and Hansol Chemical is not only a testament to scientific ingenuity but also an essential stride towards sustainable technology in the battery industry. As global regulations tighten around hazardous materials, innovations such as the APA-LC system represent a beacon of hope—melding environmental responsibility with high-performance needs. The path forward will involve continued exploration and refinement, yet the groundwork has been firmly laid for a transformative shift in battery technology that prioritizes both ecological and consumer safety.

Leave a Reply