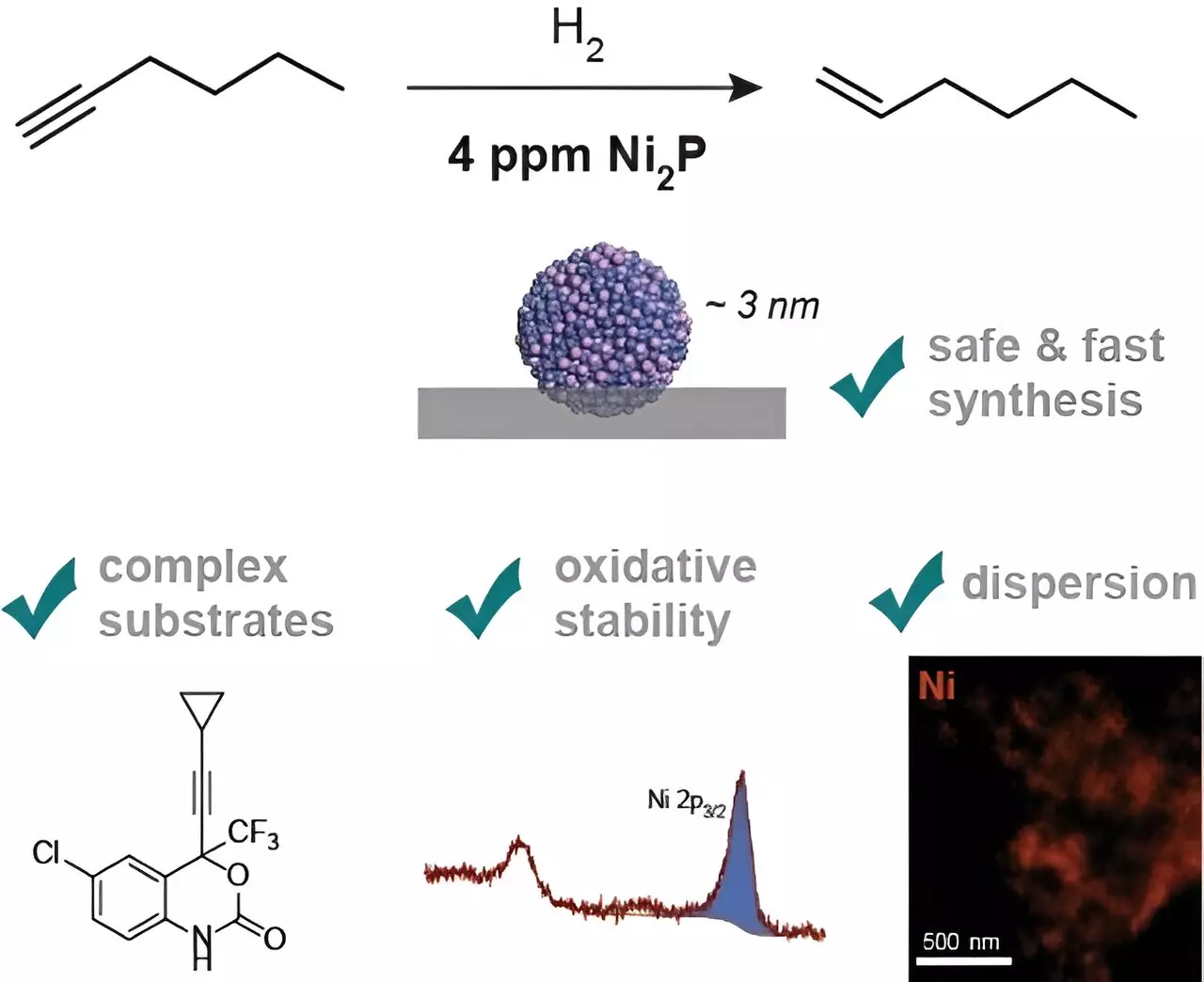

Transition metal phosphides have long been considered as a viable alternative to noble metal catalysts due to their cost-effectiveness and abundance. However, the synthesis of these catalysts has been plagued by challenges such as surface oxidation and the use of costly or toxic starting materials. Dr. Constanze Neumann and her team at the Max-Planck-Institut für Kohlenforschung in Mülheim have tackled these obstacles by implementing a novel single-step synthesis method that utilizes safe and inexpensive materials.

In their recent publication in Angewandte Chemie International Edition, Dr. Leila Karam, a Postdoc in Neumann’s group, highlights the achievement of achieving a high dispersion of the catalyst. By employing the right surface ligands, the scientists were able to uniformly distribute the catalyst on a carrier surface, ensuring its availability for the desired reaction without clumping or oxidizing prematurely. These ligands serve to protect the catalyst from unwanted oxidation while facilitating the desired reaction, allowing for the use of the catalyst in minimal quantities comparable to conventional palladium-containing alternatives.

One of the key advantages of the Mülheim catalyst is its air stability, even after storage for extended periods. Unlike other phosphides that require handling in a glovebox, this catalyst can be safely used in a standard fume hood, simplifying both storage and manipulation. Neumann expresses a desire to further improve the reusability of the catalyst and eliminate the need for solvents in its production, showcasing the team’s commitment to advancing the field of catalysis.

The development of an air-stable, nickel-containing catalyst with comparable performance to commercial palladium catalysts holds significant promise for chemical companies, particularly in selective hydrogenation processes for pharmaceutical synthesis. The ability to produce catalysts using readily available and cost-effective materials not only reduces production costs but also addresses environmental and safety concerns associated with traditional catalysts.

Looking ahead, Neumann’s group aims to further optimize the performance and sustainability of their catalyst, paving the way for widespread adoption in industrial applications. By pushing the boundaries of catalyst design and synthesis, they are poised to revolutionize the field of catalysis and unlock new possibilities for efficient and eco-friendly chemical processes.

Leave a Reply