The global increase in electronic waste (e-waste) presents an alarming challenge that demands immediate attention. As technology advances, older electronics become obsolete at an unprecedented rate, leading to staggering amounts of discarded devices rich in valuable metals. Traditional recycling methods often fall short in efficiency and ecological responsibility, emphasizing the need for innovative approaches that minimize environmental impact while maximizing metal recovery.

A groundbreaking research initiative spearheaded by James Tour at Rice University aims to change the landscape of metal extraction from e-waste. Tour, an esteemed professor in chemistry and materials science, has introduced a novel method designed to promote sustainable recycling practices. Recent findings published in *Nature Chemical Engineering* outline an evolution in recycling processes that could dramatically reduce the environmental footprint associated with metal extraction.

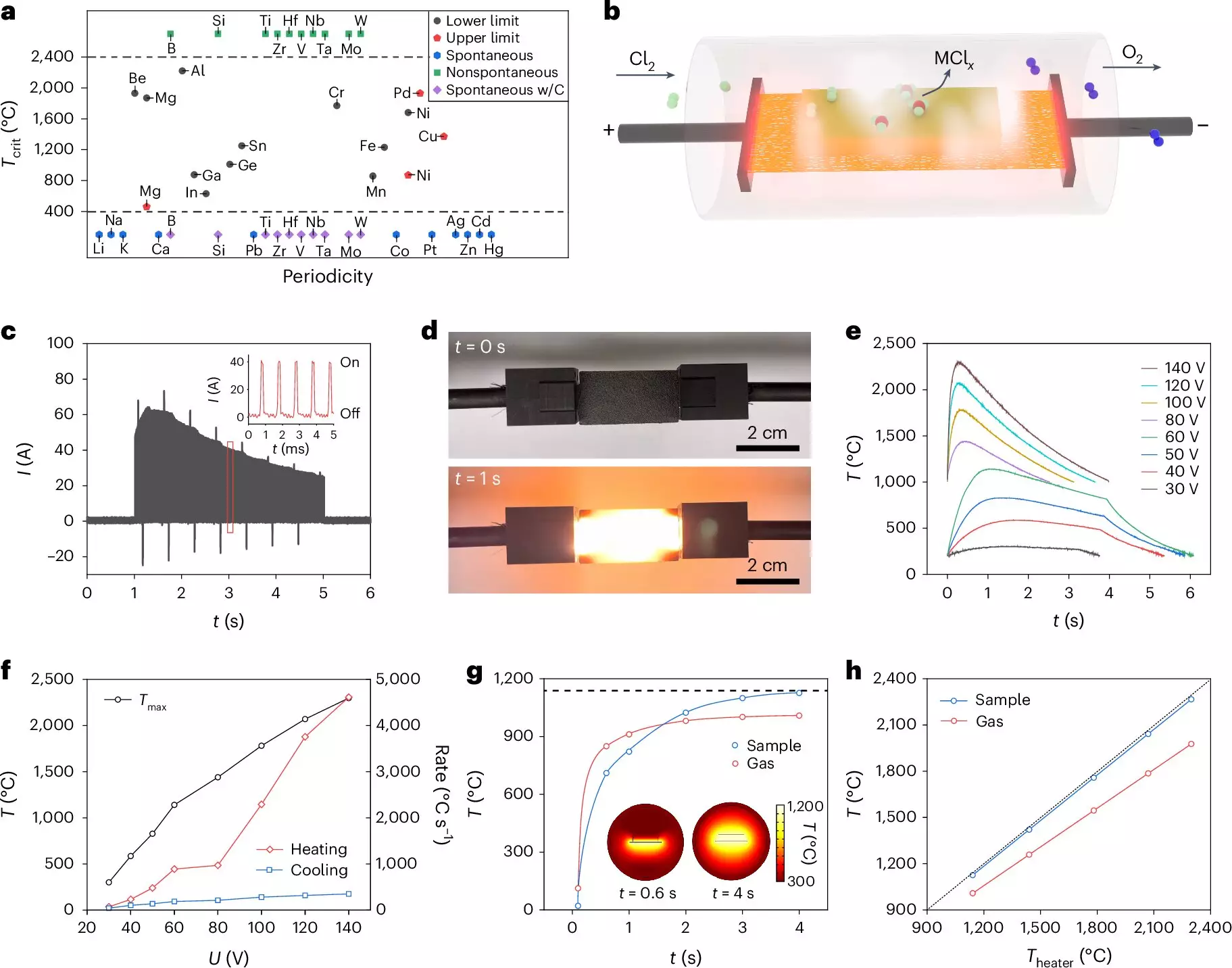

Tour’s team builds upon previous advancements in waste management through a technique called flash Joule heating (FJH). This method utilizes electric currents to rapidly elevate the temperature of materials, enabling effective transformations at the molecular level. By implementing both FJH chlorination and carbochlorination processes, the team successfully extracted significant amounts of critical metals—including gallium, indium, and tantalum—from e-waste with minimal environmental threats.

Comparison with Traditional Methods

Traditional recycling approaches, such as hydrometallurgy and pyrometallurgy, come with numerous drawbacks. These energy-intensive methods not only generate harmful byproducts but also rely heavily on acids and extensive water use, which poses a risk to ecosystems and human health. In contrast, Tour’s innovative technique leverages precise temperature controls and rapid metal separation, eliminating the dependency on hazardous materials. This pivotal advancement translates to lower operational costs and a significant reduction in greenhouse gas emissions.

Success in Metal Recovery

The research yielded impressive results, with the team achieving over 95% metal purity and an 85% recovery yield. The versatile method effectively separates desired metals from various electronic components—be it extracting tantalum from capacitors or gallium from used light-emitting diodes. Such elevated efficiency not only addresses the ongoing critical metal shortages but also champions a more sustainable approach to recycling practices, resonating with global aspirations for greener industrial methods.

The implications of this research stretch far beyond the immediate recovery of metals. The method’s adaptability holds the potential to enhance the extraction of lithium and rare Earth elements, broadening its applicability across various industries. Moreover, it instills a sense of economic motivation within the recycling sector, promising a future where efficient resource recovery is not just preferable but significantly more viable.

As the world grapples with the increasing threat of e-waste and resource depletion, the advancements made by Tour and his team illuminate a path toward a more sustainable and efficient future in electronic recycling. The collaborative efforts of researchers not only foster innovation within the scientific community but also encourage industries to rethink their methods and invest in more responsible recycling practices.

Leave a Reply