Ethylene, often referred to as the backbone of the petrochemical industry, is the key ingredient used in the production of numerous everyday products. From antifreeze and vinyl to synthetic rubber and plastics, ethylene plays a vital role in our daily lives. However, its current production method, known as steam cracking, is both energy and resource-intensive, leading to significant carbon dioxide emissions. Fortunately, researchers have made a breakthrough in an alternative process called oxidative coupling of methane (OCM), offering the potential for a greener and more sustainable method of ethylene production.

For the first time, a team of researchers from North Carolina State University (NCSU), Lehigh University, the Guangzhou Institute of Energy Conversion, and the East China University of Science and Technology have developed a highly efficient OCM catalyst that surpasses the crucial 30% yield threshold for ethylene production. Published in the prestigious journal Nature Communications, this breakthrough holds great promise for the future of ethylene production.

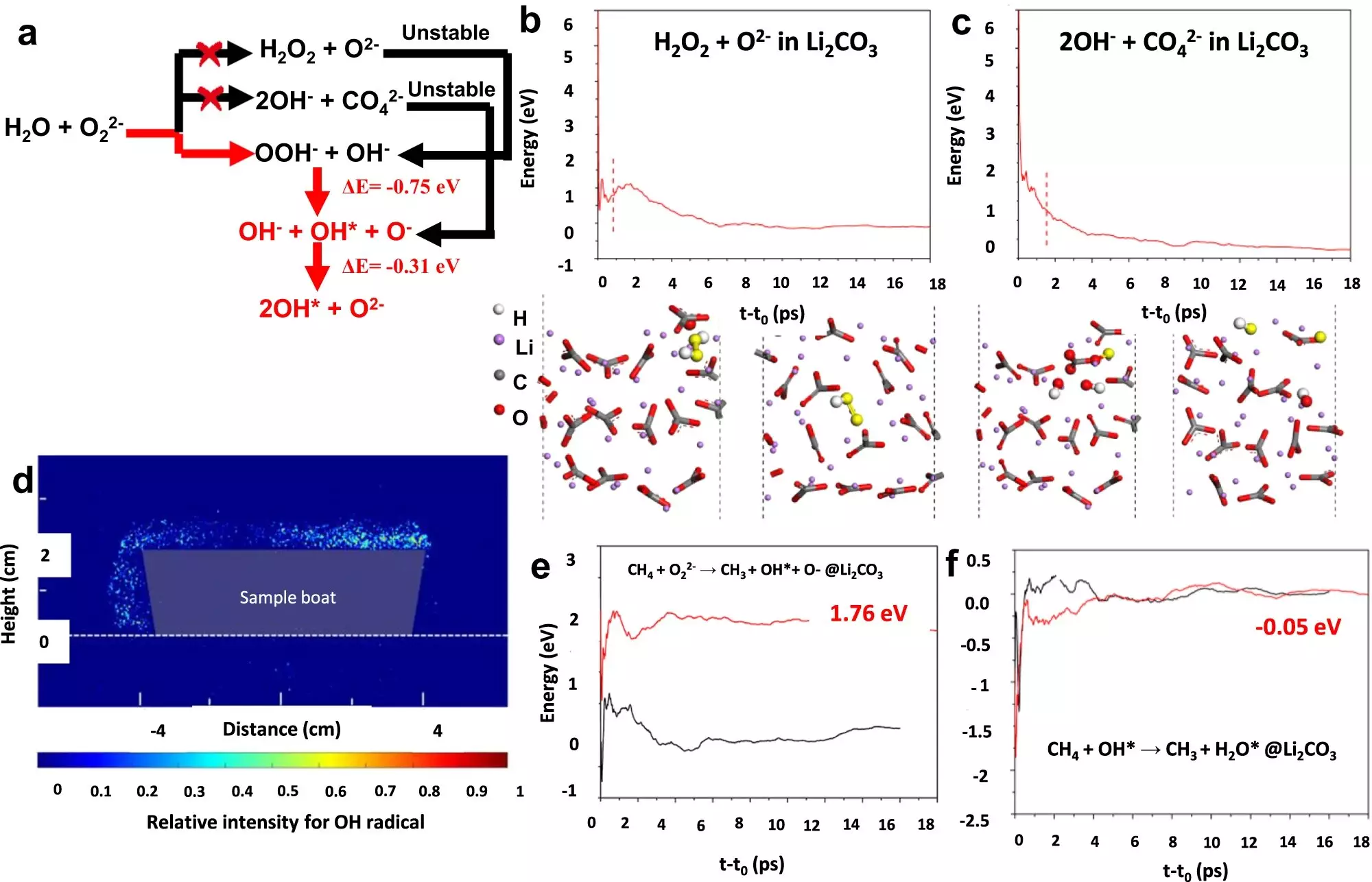

Led by Fanxing Li, Alcoa Professor of Engineering at NCSU, the research team developed a novel class of core-shell Li2CO3-coated mixed rare earth oxides as catalysts for OCM. Significantly, they employed a chemical looping scheme as the underlying mechanism for the reaction. Unlike traditional co-feeding of methane and oxygen into the catalyst chamber, the chemical looping approach allows for sequential reactions. By alternating between methane and oxygen, the catalyst undergoes a continual reoxidization process, enhancing its ability to provide oxygen for the reaction.

At Lehigh University, Bar Mosevitzky Lis and his team, working under the guidance of Israel Wachs, G. Whitney Snyder Professor of Chemical and Biomolecular Engineering, carried out the detailed characterization of the catalyst. Using in situ surface characterization techniques, they studied the catalyst’s surface transformations that occur during the reaction. The results revealed that the catalyst, consisting of a mixed oxide core coated with lithium carbonate, exhibited a high yield due to the interaction between the core and the shell during the chemical looping process.

This groundbreaking development in OCM brings methane-to-ethylene conversion within reach for industrial-scale production. By utilizing methane, primarily sourced from natural gas, and potentially from biogas and the electrochemical reduction of carbon dioxide in the future, OCM offers significant advantages in terms of cost, efficiency, energy consumption, and emissions reduction. Furthermore, once ethylene is obtained, it can be transformed into various essential products that benefit global industries.

While the catalyst’s suitability for industrial-scale production is yet to be determined, this milestone achievement represents a significant step forward. The research team is now focused on further optimizing the process to achieve higher yields and exploring the catalyst’s compatibility with large-scale applications. With the potential to revolutionize ethylene production, the OCM method promises a more sustainable and environmentally friendly future.

The discovery and refinement of an OCM catalyst that surpasses the 30% ethylene yield mark is a game-changer for the petrochemical industry. This greener alternative to steam cracking offers numerous environmental benefits, such as reduced carbon dioxide emissions and decreased reliance on crude oil. By leveraging the potential of methane and employing chemical looping, the OCM process holds the key to more cost-effective and efficient ethylene production. As researchers continue to push the boundaries and strive for higher yields, the future of ethylene production looks brighter, paving the way for a more sustainable and eco-friendly petrochemical industry.

Leave a Reply