Polyurethane foam is a versatile material that is used in a wide range of products, from mattresses to insulation in refrigerators and buildings. However, the disposal of polyurethane foam poses significant environmental and climate challenges due to its composition and the methods used to recycle it. Fortunately, researchers at Aarhus University have made a groundbreaking discovery that could revolutionize the recycling of polyurethane foam, making it more sustainable and cost-effective.

The current method of recycling polyurethane foam involves incinerating or dumping it in landfills, which not only contributes to environmental pollution but also wastes valuable resources. Most polyurethane foam products are made from components derived from fossil oil, making it crucial to find a more efficient and environmentally friendly way to recycle them. With the global market for polyurethane foam expected to reach nearly 31.3 million tons by 2030, there is an urgent need for innovative recycling solutions.

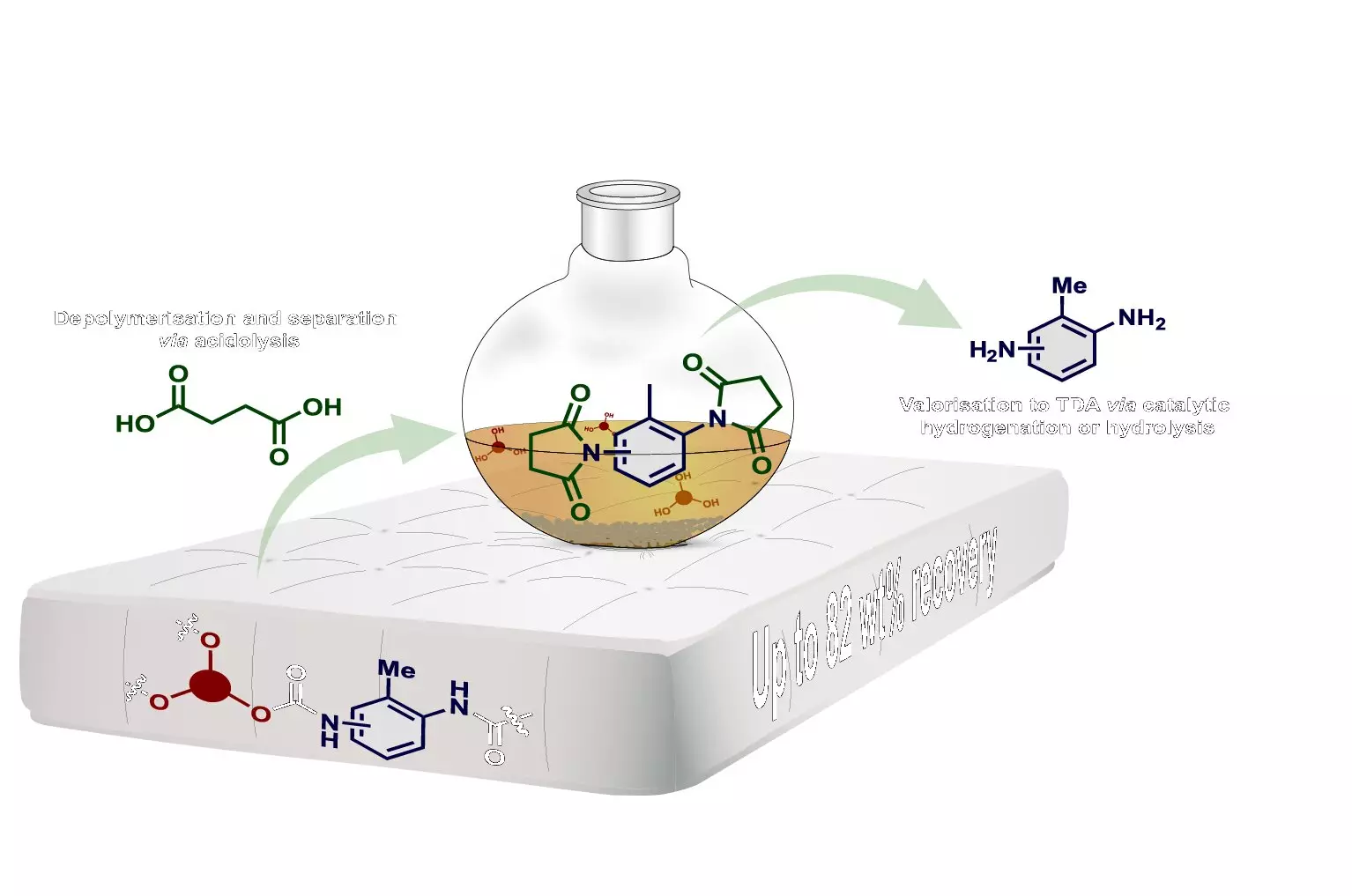

The research team at Aarhus University has developed a novel method for recycling polyurethane foam that involves breaking it down with acid (acidolysis) and separating the two main components, polyol and isocyanate. This new approach allows for the recovery of up to 82% of the original material from flexible polyurethane foam, such as that used in mattresses, in the form of two separate fractions of diamines and polyols. This breakthrough not only reduces waste but also enables the reuse of these components as raw materials in new polyurethane products.

One of the key advantages of this new recycling method is its scalability. The researchers have demonstrated that the process can be easily scaled up, making it suitable for implementation in factories that use polyurethane foam as raw material in their production. This opens up the possibility of recycling polyurethane foam waste at a large scale, reducing the environmental impact of the industry. Additionally, the quality of the recovered polyol is comparable to virgin polyol, making it a viable alternative for manufacturers seeking to incorporate sustainable practices into their production processes.

While the new recycling method shows great promise, there are still challenges that need to be addressed before a circular economy in polyurethane recycling can be achieved. Manufacturers in the polyurethane industry use unique formulae to achieve specific material properties, requiring solutions for waste sorting, logistics, and sorting polyurethane into different types. Depolymerization alone is not sufficient to ensure the success of polyurethane recycling on a large scale, highlighting the need for further research and development in this area.

The breakthrough method developed by the researchers at Aarhus University represents a significant advancement in the field of polyurethane foam recycling. By rethinking the way polyurethane foam is processed and recycled, the industry has the potential to become more sustainable and environmentally friendly. With ongoing research and development, we can look forward to a future where polyurethane waste is no longer a burden on the environment but a valuable resource in a circular economy.

Leave a Reply