Traditionally, the realm of metallic materials has been plagued by a familiar tradeoff between “strength” and “elongation.” When one property is enhanced, the other typically suffers. This dilemma has long hindered advancements in the field of metals research, as increasing a material’s strength often leads to a reduction in its elongation. This conflict has posed a significant challenge for researchers striving to improve both properties simultaneously.

An innovative technology developed by a collaborative team from POSTECH and Northwestern University has introduced a novel approach to address the age-old tradeoff between strength and elongation in metallic materials. The team, led by Professor Hyoung Seop Kim and Professor Yoon-Uk Heo from POSTECH, along with Ph.D. candidate Hyojin Park and Dr. Farahnaz Haftlang from Northwestern University, employed a technique known as “spinodal decomposition.” This process involves the spontaneous separation of a solid solution into two distinct phases, resulting in nanoscale structures with regularly arranged atoms.

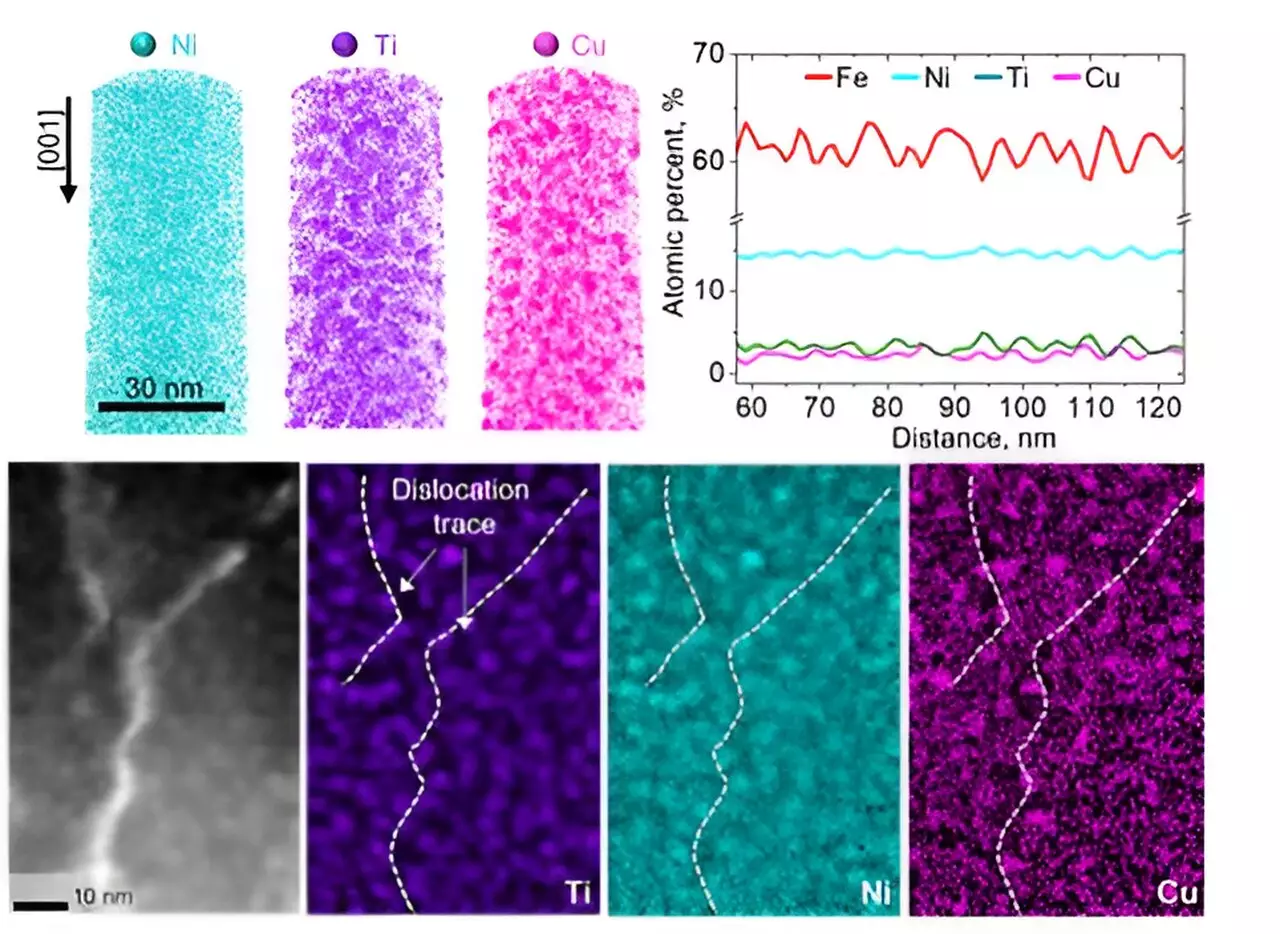

By incorporating copper (Cu) and aluminum (Al) into an iron-based medium-entropy alloy, the research team triggered periodic spinodal decomposition at the nanoscale. This innovative approach resulted in spinodal hardening, a phenomenon that enhances the material’s resistance to structural deformation. The resulting microstructure, characterized by its uniformly arranged features, effectively distributes strain throughout the material, minimizing localized deformation and increasing overall strength while preserving elongation.

Experiments conducted by the research team demonstrated the remarkable impact of their method on the mechanical properties of the alloy. Alloys produced using spinodal decomposition exhibited superior structural integrity compared to traditional alloys, achieving an impressive yield strength of 1.1 GPa (gigapascals). This represented a significant 187% improvement over the alloy without spinodal decomposition. Despite the increased yield strength, the alloy maintained nearly the same elongation of 28.5%, showcasing the effectiveness of the new approach in balancing strength and elongation.

The groundbreaking technology developed by the collaborative team from POSTECH and Northwestern University opens up new possibilities for enhancing the mechanical properties of metallic materials. By overcoming the traditional tradeoff between strength and elongation, researchers can now explore innovative ways to design alloys with improved structural integrity and durability. The implications of this research extend beyond the realm of metals research, offering a promising avenue for the development of advanced materials with enhanced properties.

The introduction of spinodal decomposition represents a significant advancement in the field of metallic materials, paving the way for the development of high-strength alloys with exceptional elongation capabilities. The collaborative efforts of the research team from POSTECH and Northwestern University have shed light on a new pathway towards enhancing the mechanical properties of metallic materials, marking a notable milestone in materials science research.

Leave a Reply