The use of samarium as a chemical reagent in the synthesis of pharmaceuticals has been a topic of interest since its discovery in a Russian mine in 1879. The challenges in scaling up the production of samarium diiodide for industrial use have hindered its full potential. However, a recent breakthrough by Caltech chemists has shown promise in addressing this issue by allowing the reagent to recycle itself for repeated use in a single reaction.

The Scaling-Up Challenge

One of the main obstacles in using samarium diiodide on an industrial scale has been its air sensitivity, which requires fresh preparation before each reaction. Additionally, large amounts of the reagent are necessary even for small reactions, making it impractical for industrial use. This limitation has confined the use of samarium to academic labs where it is used for the synthesis of natural products.

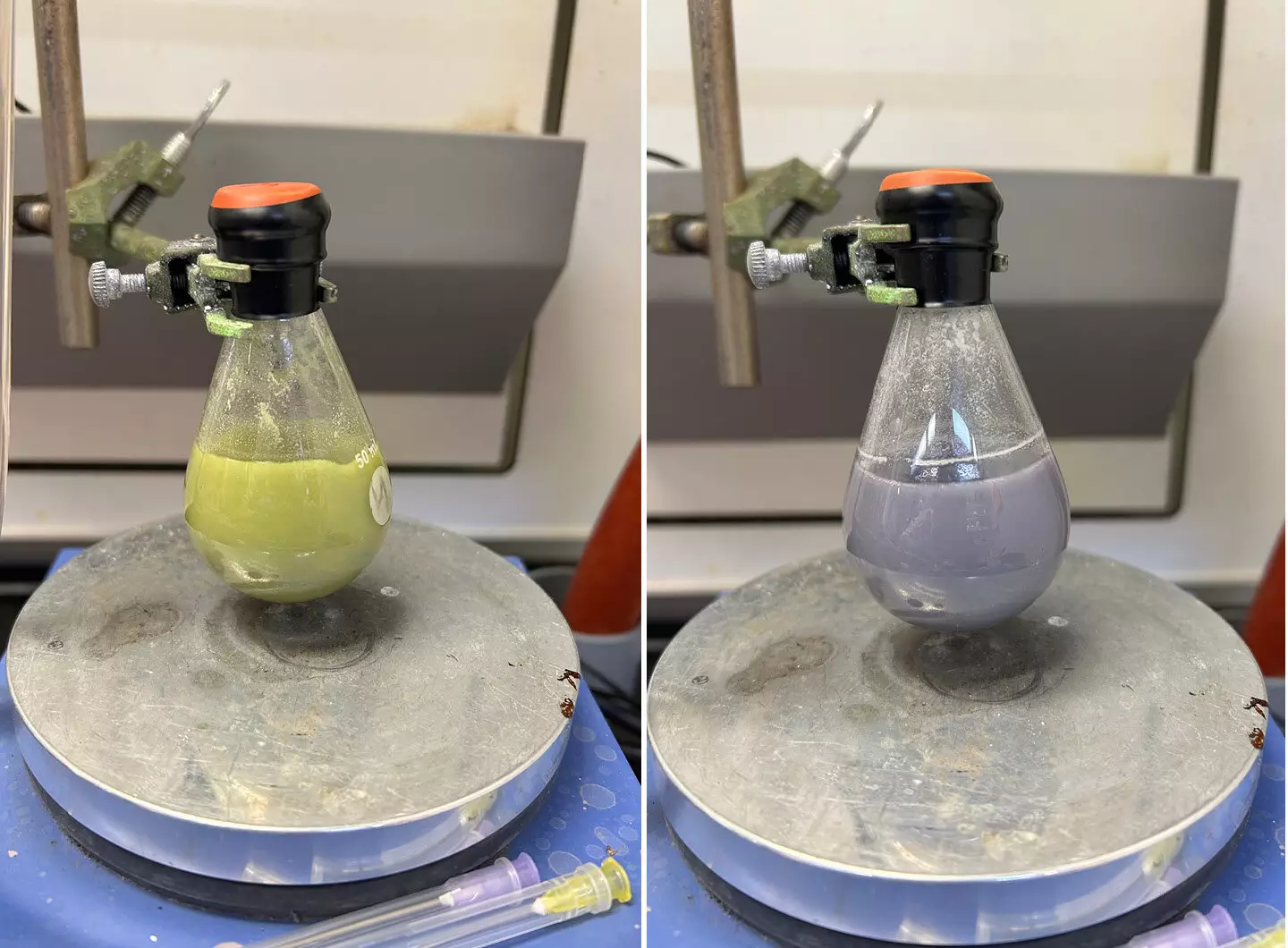

In the study titled “Reductive samarium (electro)catalysis enabled by SmIII-alkoxide protonolysis,” Caltech chemists have found a way to overcome the challenges associated with scaling up the use of samarium diiodide. By developing a method that allows the reagent to recycle itself during a reaction, the need for large amounts of solvents and fresh preparations has been eliminated. This breakthrough opens up the possibility of using samarium reagent for industrial-scale reactions.

Breaking the Samarium-Oxygen Bond

One of the key issues with the samarium reagent has been the formation of a stubborn samarium-oxygen bond during reactions, rendering the reagent inactive. Previous attempts to recycle samarium back to its active state have required harsh chemicals. However, the Caltech researchers were able to cleave this bond using a mild acid, making the process more practical for large-scale reactions. This breakthrough has paved the way for the reagent to be used in industrial settings.

The collaboration between Caltech graduate students Chungkeun Shin and Emily Boyd, along with researchers from the Reisman and Peters labs, has been instrumental in the success of this study. By combining their expertise in chemistry and sustainability, the team was able to develop a method to effectively recycle the samarium reagent for repeated use in reactions. This interdisciplinary approach has shown great promise in advancing the field of chemical synthesis.

The use of samarium diiodide in nitrogen fixation research by the Peters lab highlights the potential applications of this reagent beyond pharmaceutical synthesis. Nitrogen fixation, a crucial process for plant growth and food production, can now be studied more effectively using samarium reagent. The ability to scale up this process for industrial use could have far-reaching implications for sustainable agriculture and food security.

The breakthrough in scaling up the use of samarium diiodide for industrial reactions marks a significant advancement in the field of chemical synthesis. The method developed by Caltech chemists has the potential to revolutionize the way pharmaceuticals and other chemical compounds are synthesized on a large scale. By overcoming the challenges associated with the reactivity of samarium reagent, this study paves the way for new discoveries and innovations in chemistry.

Leave a Reply