Ceramics have long been prized for their mechanical strength, chemical inertness, and resistance to wear and corrosion. However, their lack of plastic deformability at room temperature has limited their industrial applications. Researchers at Purdue University’s College of Engineering have recently developed a groundbreaking method to enhance the plasticity of ceramics, opening up new possibilities for their use in a variety of industries. This innovative approach, pioneered by Haiyan Wang and Xinghang Zhang, has the potential to revolutionize the field of ceramic materials.

The Problem of Plasticity in Ceramics

Traditionally, ceramics have been known for their brittleness at room temperature, which stems from their limited ability to deform plastically under compression, tension, or shear forces. Unlike metals, which exhibit ductile behavior and can bend without breaking, ceramics have few dislocations that allow for plastic deformability. Dislocations are defects in materials that alter the arrangement of atoms in a structure and enable plasticity. Wang and Zhang recognized this fundamental challenge and sought to address it through a novel method.

Enhancing Plastic Deformability

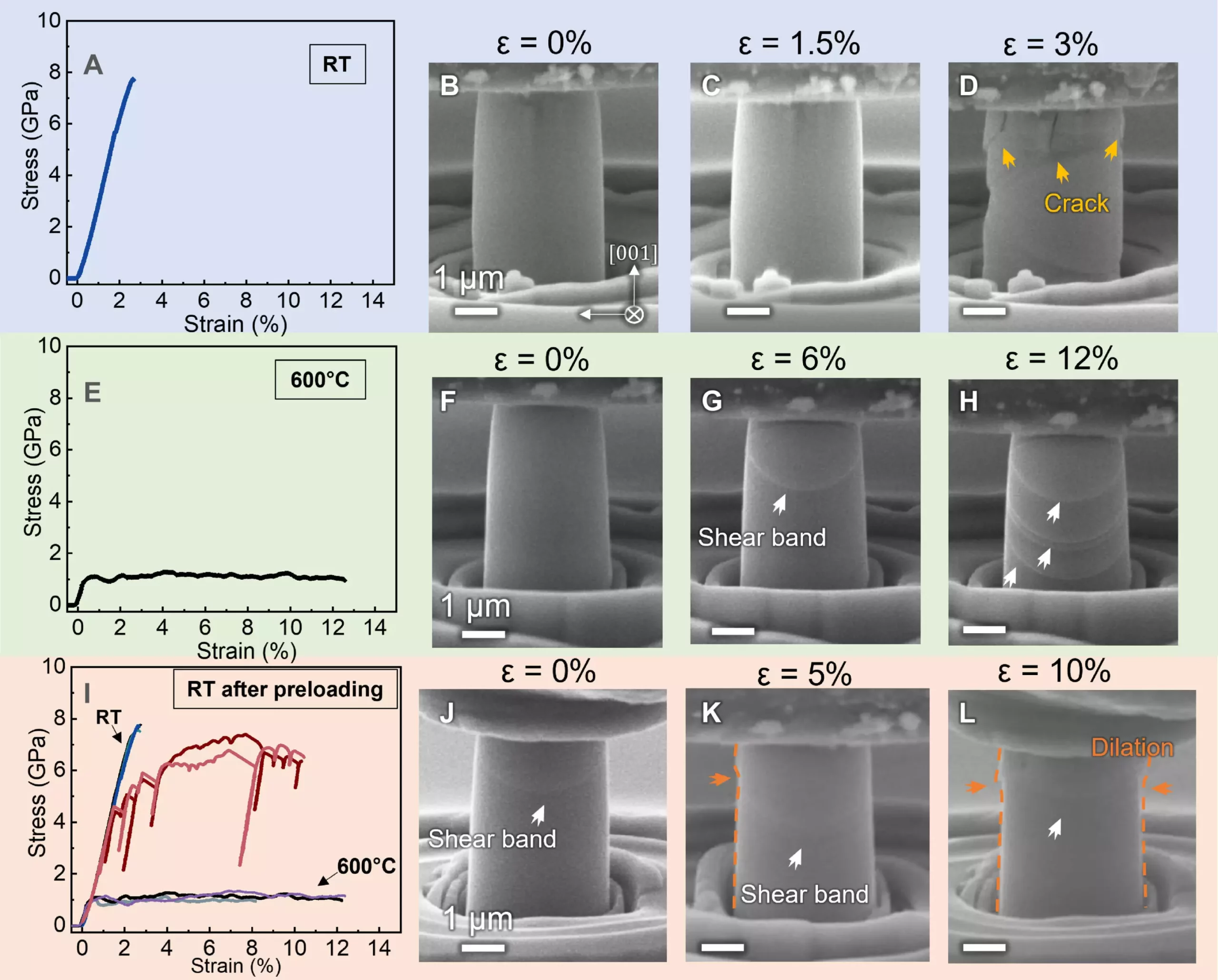

The Purdue team’s method involves introducing high-density defects into brittle ceramics at elevated temperatures, thereby improving their room-temperature plastic deformability. By preloading ceramic materials with dislocations during deformation, the researchers were able to significantly increase their ability to be deformed without fracturing. This breakthrough has the potential to inject ductility into ceramics, making them more versatile and adaptable for a wide range of applications.

Ceramic materials are widely used in industries such as aerospace, transportation, power generation, and manufacturing due to their unique properties. They serve as structural components, insulating materials, coatings, and more, in critical applications where high strength and durability are required. With the newfound ability to enhance ceramic plasticity, these materials can now be used in even more demanding environments and applications that were previously inaccessible.

The Purdue research team has conducted extensive testing and validation of their method on various ceramic systems and structures. They have demonstrated significant improvements in deformability, with materials like single-crystal titanium dioxide achieving 10% strain at room temperature. This level of plasticity was previously unthinkable for ceramics, showcasing the transformative potential of this new approach. The researchers have also tested the method on aluminum oxide, which exhibited 6% to 7.5% strain, further confirming its effectiveness.

Moving forward, the research team plans to collaborate with industry partners to demonstrate the scalability and practicality of their method on a larger scale. By working with key stakeholders in the ceramics industry, they hope to bring this innovative approach to market and unlock its full potential. The Purdue Innovates Office of Technology Commercialization has already applied for a patent to protect the intellectual property associated with this groundbreaking method, setting the stage for future commercialization efforts.

The development of a method to enhance the plastic deformability of ceramics represents a major leap forward in materials science and engineering. By overcoming the traditional limitations of ceramic materials, researchers at Purdue University have opened up new opportunities for innovation and application in a wide range of industries. The future of ceramics looks brighter than ever, thanks to the pioneering work of Wang, Zhang, and their team.

Leave a Reply