The world’s transition to electric vehicles has been hindered by the reliance on cobalt, a metal with significant financial, environmental, and social costs. However, MIT researchers have recently made a groundbreaking discovery that could revolutionize the electric car industry. They have designed a battery material that offers a more sustainable way to power electric cars, using organic materials instead of cobalt or nickel. This new lithium-ion battery material not only reduces costs but also exhibits similar conductivity and storage capacity to traditional cobalt-containing batteries. Furthermore, it has the added advantage of faster charging capabilities. The implications of this breakthrough are profound, as it addresses the cost, environmental, and ethical concerns associated with cobalt mining for battery production.

Most electric cars rely on lithium-ion batteries, which have a cathode containing cobalt. However, cobalt extraction carries significant downsides. Firstly, cobalt is a scarce metal, causing its price to fluctuate dramatically. Additionally, most cobalt deposits are located in politically unstable countries, posing a risk to the stability of the supply chain. The extraction process itself is wrought with hazardous working conditions and generates toxic waste, contaminating the surrounding land, air, and water. These factors make cobalt mining unsustainable and highlight the urgent need for alternative battery materials.

In response to the drawbacks of cobalt, extensive research has been conducted to develop alternative battery materials. One such material is lithium-iron-phosphate (LFP), which has gained some traction in the electric vehicle industry. However, it falls short in terms of energy density compared to cobalt and nickel batteries. Organic materials have also been explored as a potential solution, but their low conductivity has been a significant limitation. Most organic materials require the addition of binders, such as polymers, to maintain conductivity. Unfortunately, these binders reduce the battery’s storage capacity, offsetting the advantages of organic materials.

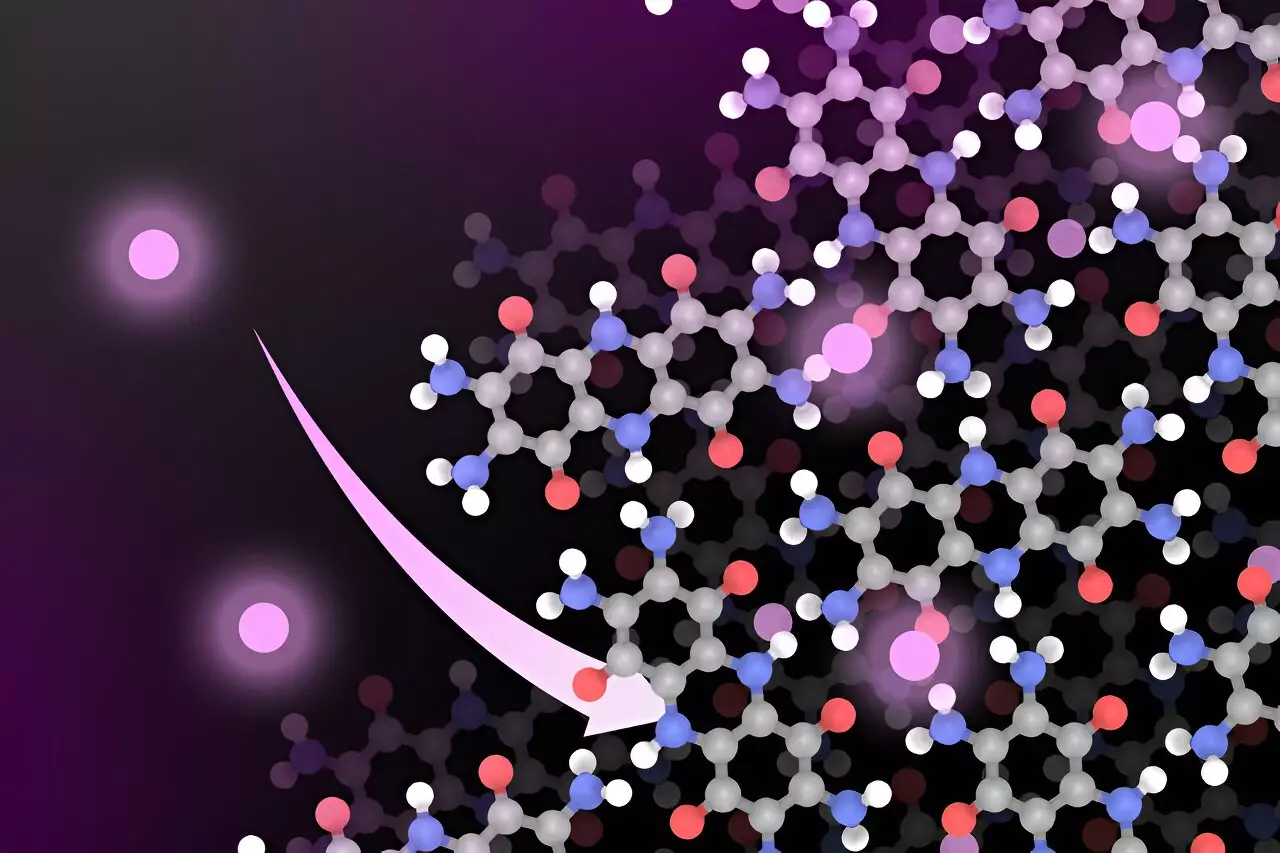

Researchers at MIT, funded by Lamborghini, embarked on a project to develop an organic battery capable of powering electric cars. During this endeavor, they stumbled upon a fully organic material that demonstrated promising conductivity. This material, known as TAQ (bis-tetraaminobenzoquinone), consists of layers of organic compounds with a structure similar to graphite. Within these layers are quinones, serving as electron reservoirs, and amines, fostering strong hydrogen bonds. The material’s insolubility prevents it from dissolving into the battery electrolyte, enhancing its longevity. Extensive testing revealed comparable conductivity and storage capacity to cobalt-containing batteries.

Batteries utilizing TAQ cathodes exhibit remarkable characteristics. They can be charged and discharged faster than existing batteries, significantly reducing charging times for electric vehicles. To improve stability and adherence to the battery’s current collector, filler materials such as cellulose and rubber are added in minimal quantities. These fillers prevent the cathode from cracking during charging, enhancing the battery’s lifespan. Crucially, the primary materials needed for manufacturing TAQ cathodes are commercially available and produced in large quantities, ensuring scalability and affordability.

The advent of sustainable battery materials brings hope for the future of electric vehicles. By replacing cobalt-containing batteries with organic alternatives, the cost, environmental, and ethical implications can be significantly reduced. The MIT researchers estimate that the material cost for producing organic batteries could be as low as one-third to one-half the cost of cobalt batteries, making them a feasible and affordable option. Furthermore, Lamborghini has recognized the potential of this breakthrough and has already licensed the patent on the technology.

MIT’s breakthrough in organic battery materials is just the tip of the iceberg. The researchers plan to continue exploring alternative battery materials and are investigating the possibility of using sodium or magnesium as replacements for lithium. Both sodium and magnesium are cheaper and more abundantly available, further reducing the reliance on scarce and costly resources. The future of electric cars looks brighter with every sustainable innovation that emerges, paving the way for a greener and more accessible transportation sector.

The MIT researchers’ new lithium-ion battery material represents a crucial step towards sustainable electric vehicles. By eliminating cobalt and nickel from battery production, they have addressed major challenges related to cost, environmental impact, and ethical concerns. The potential for organic battery materials to revolutionize the industry and accelerate the adoption of electric vehicles cannot be underestimated. With ongoing research and development, the future holds promise for even more advanced and sustainable battery technologies.

Leave a Reply