The recent publication of the paper, “Robust Macroscale Superlubricity on Carbon-Coated Metallic Surfaces,” by the president of SUNY Polytechnic Institute (SUNY Poly), Dr. Winston “Wole” Soboyejo, and postdoctoral researcher Dr. Tabiri Kwayie Asumadu, represents a groundbreaking advancement in the field of reducing friction on metallic surfaces. This innovative approach to achieving superlubricity at the macroscale level is a substantial leap forward that has the potential to revolutionize various industries.

The findings of this research, which have been published in the journal Applied Materials Today, have significant practical implications across different sectors. In the automotive industry alone, where more than 30% of fuel is utilized to overcome friction in passenger vehicles, the application of these novel carbon coatings could lead to substantial improvements in fuel efficiency. Similarly, in manufacturing and industrial machinery, the reduction of wear and tear through the implementation of these coatings could result in significant cost savings and a decrease in the percentage of countries’ GDP spent on friction-related equipment issues.

Dr. Asumadu aptly points out that the impact of this research extends beyond a single industry, stating that “From biomedical to energy sectors to nearly every kind of manufacturing, this approach could help to extend the life of machine parts, reduce maintenance and replacement costs, and create a more sustainable industrial future.” The interdisciplinary potential of this breakthrough in superlubricity cannot be understated, as it has the capacity to transform various sectors through its practical applications.

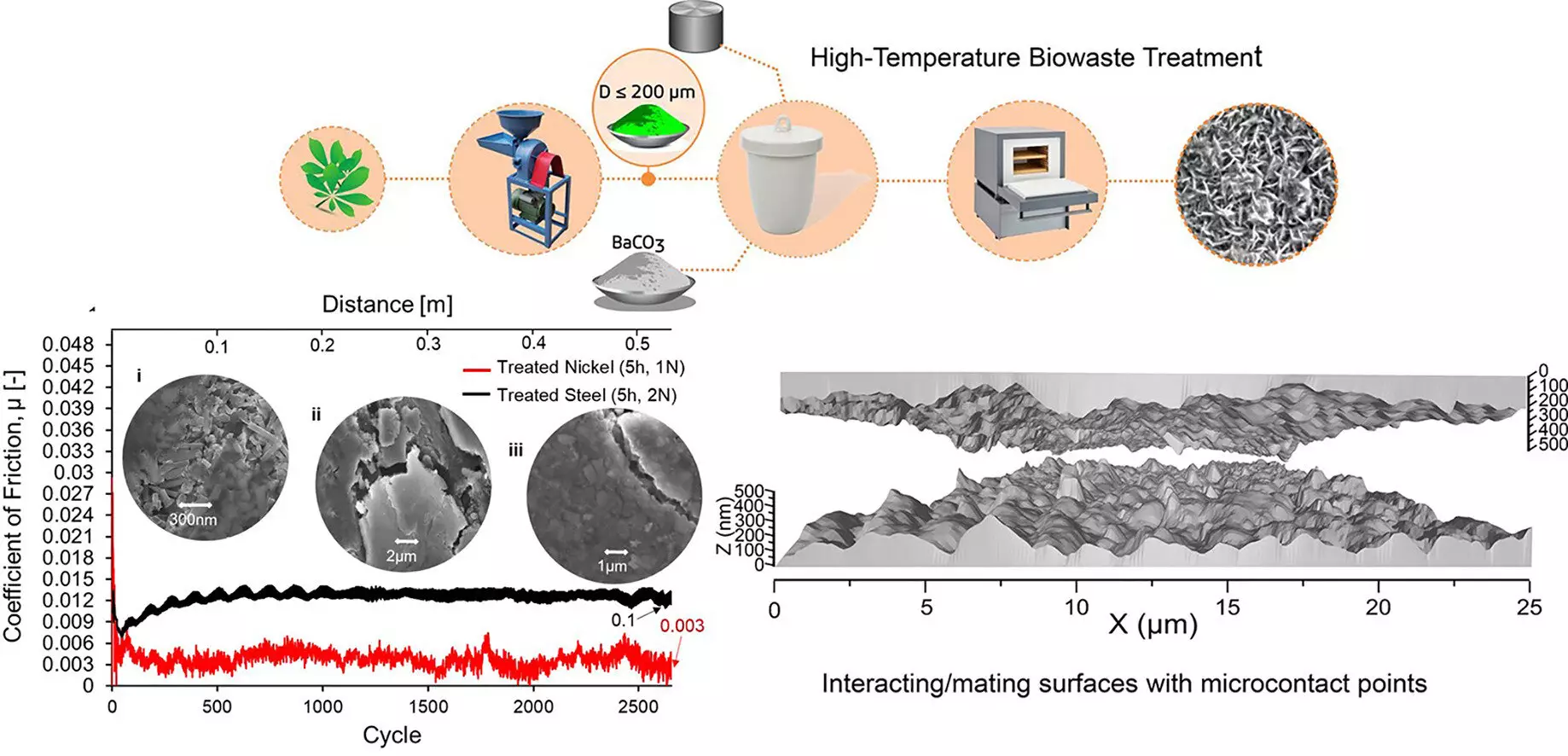

The experimental and computational results presented in the paper showcase the ultralow friction achieved through carbon-coated metallic depositions on substrates of structural steels, Ti, and Ni alloys. The use of sustainably produced carbon coatings made from biowaste represents a novel approach that has resulted in macroscale superlubricity being maintained over extended periods under regular atmospheric conditions. By utilizing carbon nanocrystals with variants of graphene footprints deposited on metallic surfaces through a high-temperature biowaste treatment process, the researchers have successfully demonstrated a coefficient of friction of ~0.003, indicating near-zero friction levels.

The use of biowaste as a carbon source for these coatings aligns with the principles of a circular economy, emphasizing material recycling and reducing the global carbon footprint. The implications of this research extend beyond technological advancements to encompass environmental and economic considerations, making it a significant contribution towards creating a more sustainable future. The collaborative effort of a group of materials scientists across Africa and the Northeastern United States highlights the global importance and impact of this research, emphasizing the potential for widespread adoption and implementation.

The research conducted by Dr. Winston “Wole” Soboyejo and Dr. Tabiri Kwayie Asumadu represents a major step forward in the field of superlubricity and has the potential to revolutionize multiple industries. The practical applications, interdisciplinary potential, and environmentally conscious approach make this research a significant contribution towards creating a more sustainable and efficient industrial future.

Leave a Reply