Gas detection has long been a crucial aspect of industrial and domestic safety measures. However, most existing systems have limitations in terms of their sensitivity, durability, and cost-effectiveness. Researchers at MIT have recently developed a groundbreaking detector that overcomes these challenges, offering continuous monitoring for toxic gases at a low cost. This new system combines the advantages of two distinct technologies – metal-organic frameworks (MOFs) and conductive polymers – to create a reliable and reusable detector.

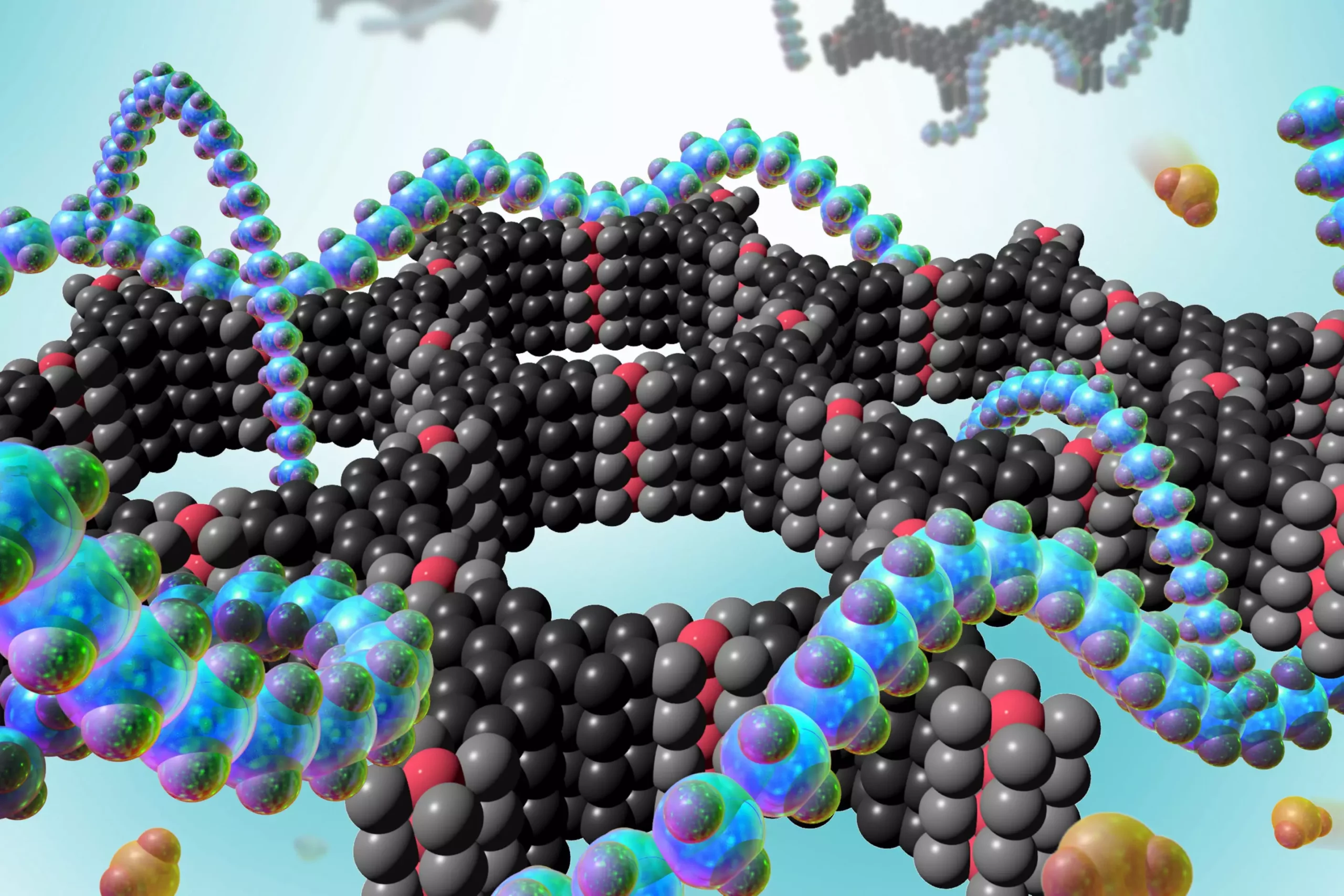

MOFs are known for their high sensitivity to trace gases, making them ideal for gas detection. However, their performance degrades rapidly with use, limiting their practical application. On the other hand, conductive polymers are more durable and easier to process but lack the sensitivity of MOFs. By combining these materials in a one-to-one ratio, researchers have achieved a sensor that offers both high sensitivity and reversibility. The liquid solution containing the polymers and MOFs is deposited on a substrate to form a thin, uniform coating that can detect changes in electrical resistance when gas molecules are trapped temporarily.

The composite material developed by the MIT researchers has been shown to detect nitrogen dioxide, a common toxic gas, at concentrations as low as 2 parts per million. The material’s ability to maintain its baseline performance after 100 cycles of detection demonstrates its long-term durability and potential for continuous monitoring. This is a significant improvement over existing detectors for nitrogen dioxide, with implications for areas such as combustion emissions and asthma prevention. The material’s thin film form allows for easy application in various settings, from handheld devices to industrial coatings.

The versatile nature of the composite material opens up possibilities for detecting various volatile molecules beyond nitrogen dioxide. As the chemistry can be tailored to target specific gases, the material may find applications in detecting a wide range of toxic gases in different environments. The ease of production and low material costs associated with the thin film form make it a promising candidate for scaling up in real-life settings. From monitoring exhaust pipes to chimneys, the material has the potential to revolutionize gas detection and improve safety standards across industries.

The development of a composite material combining MOFs and conductive polymers represents a significant advancement in gas detection technology. The ability to provide continuous monitoring for toxic gases at a low cost opens up new possibilities for improving safety and environmental standards. With further research and development, the potential applications of this innovative material are vast, offering a promising future for continuous gas monitoring systems.

Leave a Reply