The Department of Energy’s Pacific Northwest National Laboratory has spearheaded groundbreaking research that could revolutionize the world of electric vehicles (EVs) as we know it. By making a seemingly simple shift in lithium-ion battery manufacturing, the potential for EVs to store more energy per charge and endure more charging cycles is within reach. This pioneering approach focuses on synthesizing single-crystal, high-energy, nickel-rich cathodes, offering a cost-effective alternative to conventional methods. With the publication of their findings in Energy Storage Materials, the team at Pacific Northwest National Laboratory hopes to address the current bottleneck in EV battery performance: the positive electrode, or cathode.

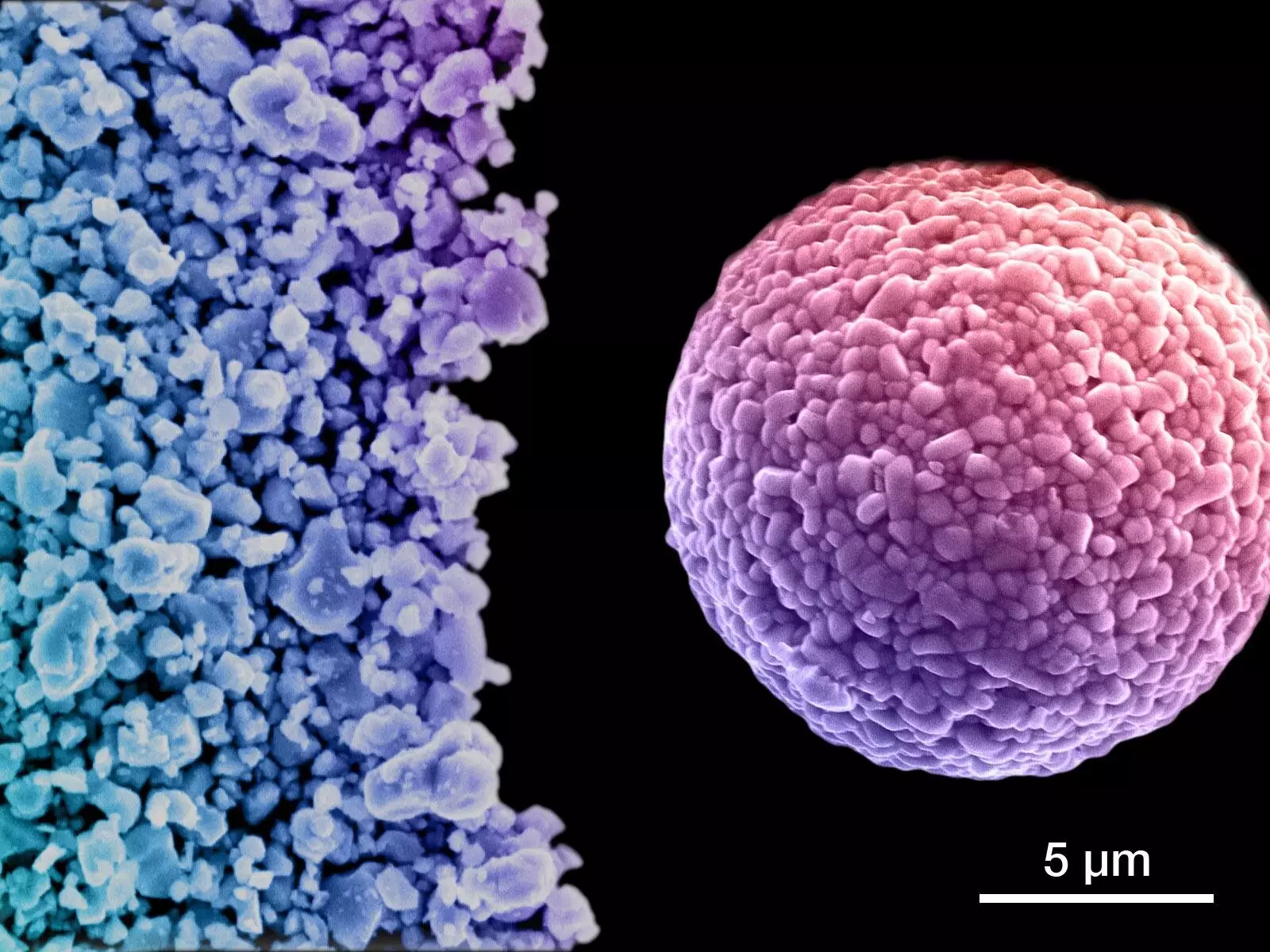

The current standard for cathodes in lithium-ion EV batteries utilizes a combination of metal oxides known as lithium nickel manganese cobalt oxides, abbreviated as NMC. By increasing the nickel content in these cathodes, their energy storage capacity and, consequently, the range of EVs can be greatly enhanced. The emergence of nickel-rich NMC cathodes, such as NMC811 (containing 80% nickel), has generated significant interest within the industry. However, the manufacturing process for high-nickel NMC cathodes leads to the formation of rough, lumpy polycrystal structures. While this texture has proven advantageous for regular NMC, it becomes problematic for NMC811 and beyond. These bulbous polycrystal structures are prone to splitting, resulting in material failure, cracking, and accelerated decay. Finding a solution is crucial.

To overcome the limitations of conventional manufacturing methods, the researchers at Pacific Northwest National Laboratory sought to convert the lumpy, polycrystal NMC into a smooth, single-crystal form. The challenge lay in achieving this conversion using lower-cost, solid-state methods, which are more practical for real-world cathode manufacturing. Previous attempts to grow single crystals involved using environments such as molten salts or hydrothermal reactions, but these were not feasible for large-scale production. Instead, the team introduced a pre-heating step during synthesis which altered the structure and chemical properties of the transition metal hydroxide, paving the way for the production of uniform single-crystal NMC structures.

The next step was to test the scaled single crystals in realistic 2Ah lithium-ion pouch cells – a key benchmark for evaluating the battery’s performance. The results were nothing short of remarkable. Even after 1,000 charge and discharge cycles, the first prototype battery equipped with the scaled single crystals remained stable, without any defects or loss of performance. This breakthrough has enormous implications for the commercial viability of lithium batteries with high energy density as it allows for their use without degradation over time. Accomplishing this feat is crucial for the widespread adoption of EVs, especially in creating a sustainable future powered by clean renewable energy sources.

The synthesis method for single-crystal, nickel-rich cathodes not only leverages innovation but also offers a cost-efficient and scalable approach. The drop-in nature of this method allows cathode manufacturers to integrate the production of single-crystal NMC811 seamlessly. Additionally, it opens the door for the development of cathodes with even higher nickel content. Jie Xiao, the principal investigator of the project, emphasizes that this represents a fundamental shift in large-scale production of single crystal cathode materials. The team is now focused on scaling up the production process, starting from raw materials and utilizing conventional manufacturing equipment. Collaborating with industry and university partners, Pacific Northwest National Laboratory aims to bring this technology to commercial fruition by addressing the scientific challenges and engineering opportunities that lie ahead.

It is important to note that Pacific Northwest National Laboratory is not in competition with the industry. Instead, they are working hand-in-hand with industry partners to drive innovation and develop a sustainable pathway toward commercial-scale manufacturing. With the support of stakeholders, they aim to accelerate the adoption of single-crystal cathodes, paving the way for more efficient and long-lasting lithium-ion batteries. This breakthrough technology will not only make EVs more practical and resilient but also contribute to the global goal of reducing greenhouse gas emissions and transitioning to a cleaner energy future.

The research conducted by Pacific Northwest National Laboratory has unlocked the potential of single-crystal cathodes, offering a groundbreaking solution to the limitations of traditional lithium-ion battery manufacturing. By enhancing the energy storage capacity and durability of EV batteries, this innovative approach brings us one step closer to a sustainable transportation future. The collaboration between academia, national laboratories, and industry partners is crucial in turning this research into a scalable reality. With this paradigm shift, the commercialization of lithium batteries with high energy density becomes more attainable, taking us closer to a world powered by renewable energy sources. As we embrace the era of electric mobility, the future is brighter than ever before.

Leave a Reply