When it comes to effectively combining hard and soft materials, nature has already perfected the art. Take, for example, the bone-tendon connections in the human body. Despite the stark difference in hardness between bones and tendons, these intersections never fail. Drawing inspiration from this remarkable natural design, a team of researchers from TU Delft’s faculty of Mechanical, Maritime and Material Engineering (3mE) has developed a unique 3D printing process to create hybrid multi-material interfaces that closely mimic nature’s genius. Recently published in Nature Communications, their groundbreaking research findings hold immense potential for a wide range of applications.

Overcoming Mismatched Interfaces

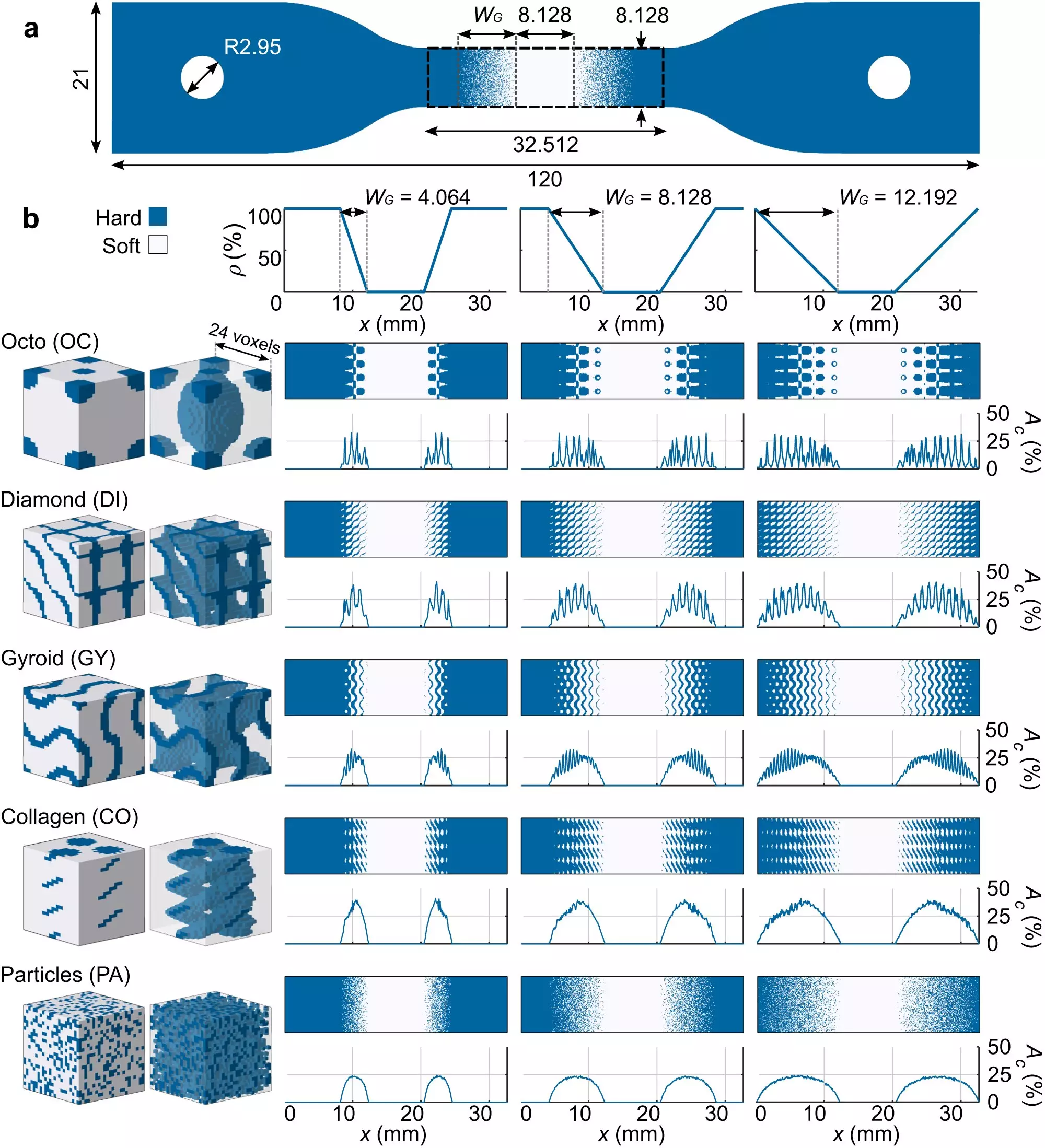

In any connection between two materials, a disparity in hardness often leads to stress concentration and subsequent failure of the softer material. To address this challenge, Professor Amir Zadpoor, an expert in Biomaterials and Tissue Biomechanics, explains the importance of a gradual change in material properties at the interface. Unlike abrupt transitions, a smooth and gradual change helps to distribute mechanical stress evenly, preventing localized concentration. Keeping this principle in mind, the researchers employed different geometries and a multi-material 3D printing technique to increase the contact area between hard and soft interfaces, effectively emulating the natural design observed in bone-tendon connections.

Optimizing Strength and Toughness

In designing these interfaces, another crucial consideration is ensuring that the strength of the interface matches that of the soft material. Dr. Mauricio Cruz Saldivar, the first author of the research manuscript, explains that exceeding the strength of the soft material is futile, as failure will invariably occur in the weaker component. By adhering to this principle and employing their novel approach, the researchers were able to enhance toughness values of interfaces by an impressive 50% compared to a control group. This research breakthrough not only pushes the boundaries of what is theoretically possible but also provides valuable design guidelines for improving the mechanical performance of bioinspired soft-hard interfaces, applicable across various fields.

Beyond its inherent scientific significance, the technique developed by the research team offers practical advantages. Unlike traditional methods that require multiple steps and rely on adhesives to combine different materials, this innovative approach enables the creation of a whole product at once. Assistant Professor Zjenja Doubrovski emphasizes the elimination of unnecessary complexity, allowing for the seamless integration of multiple exotic materials, each with unique properties. This versatility widens the scope of potential applications, ranging from medical devices and soft robotics to flexible devices.

While the current achievements of this research are already impressive, the team has even grander aspirations for the future. One particularly exciting prospect is the integration of living cells into these interfaces, opening new doors in the field of regenerative medicine. Assistant Professor Mohammad J. Mirzaali envisions the possibility of connecting implants to surrounding soft tissue, facilitating the regeneration of bone and muscle. By incorporating living cells, the complexity of the construct increases exponentially, taking us one step closer to unlocking the full potential of these innovative interfaces.

In their relentless pursuit of optimizing the mechanical performance of material interfaces, TU Delft researchers have made significant strides. By mimicking the gradual transition and strength matching observed in nature, their groundbreaking multi-material 3D printing process brings us closer than ever to bridging the gap between hard and soft materials. The research findings not only provide invaluable design principles but also pave the way for a myriad of future applications. From medical breakthroughs to advancements in robotics and beyond, the future of material interfaces holds boundless possibilities. As this field continues to evolve, we eagerly anticipate the discoveries and innovations that lie ahead.

Leave a Reply