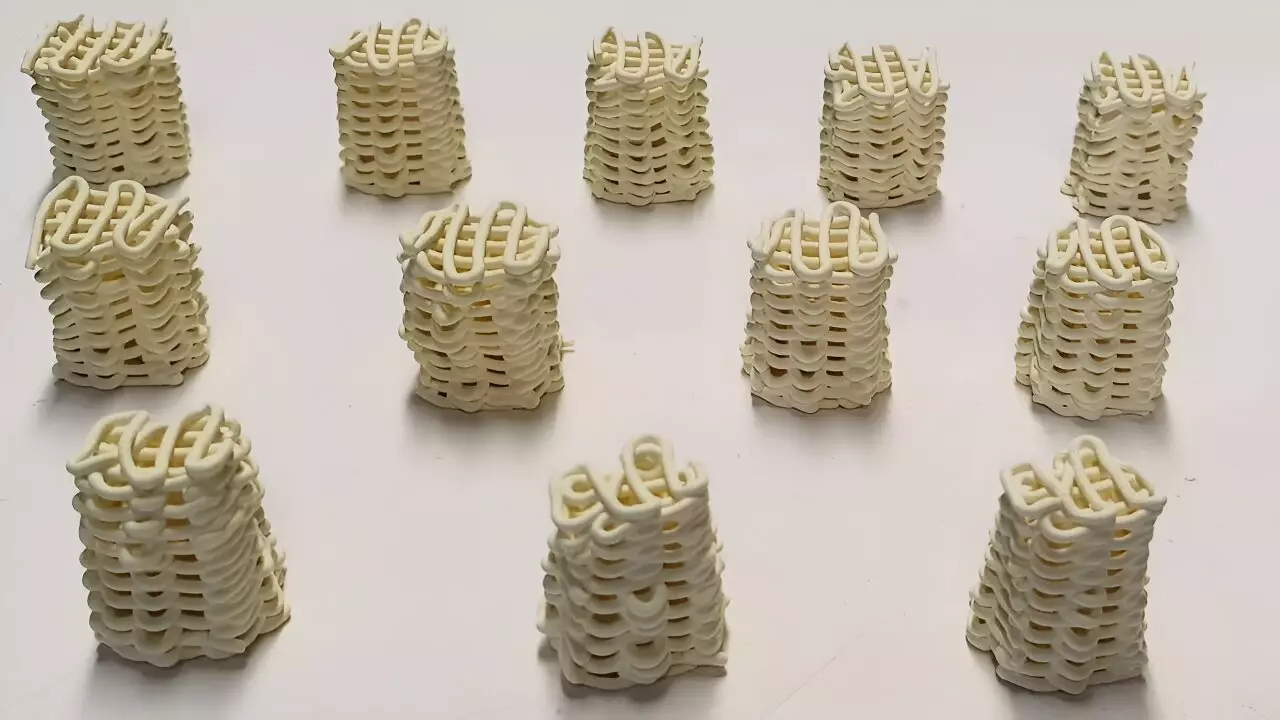

The University of Bath has recently made groundbreaking advancements in water purification techniques by utilizing 3D printing technology. Through the creation of ceramic-infused lattices, known as ‘monoliths,’ researchers have successfully demonstrated the removal of at least 75% of perfluorooctanoic acid (PFOA), a harmful chemical commonly found in water sources. This innovative approach has the potential to revolutionize the way we address the growing concern of ‘forever chemicals’ in our water supplies.

Perfluoroalkyl and polyfluoroalkyl substances (PFAS), often referred to as ‘forever chemicals,’ pose a significant risk to public health due to their persistent nature and long-term effects. These man-made compounds have been linked to various health issues, including reproductive disorders, cardiovascular complications, and an increased risk of diabetes. PFAS can be found in everyday products such as non-stick cookware, raincoats, paints, and firefighting foams, making their presence in water sources a pressing concern.

The key to the success of the University of Bath’s method lies in the creation of ceramic-infused lattices using 3D printing technology. By incorporating ceramic indium oxide into the structure of the monoliths, researchers have developed a highly efficient filtration system that effectively captures and removes PFAS from water. The 3D printing process allows for the production of intricate lattice shapes with a high surface area, essential for maximizing the removal of contaminants.

One of the significant advantages of this new water purification method is its scalability and energy efficiency. The 3D printing process enables the rapid production of monoliths that can be easily deployed in water treatment systems. Once the monoliths are placed in water, they effectively trap PFAS molecules, providing a simple and effective solution for water purification. The process is not only efficient but also cost-effective, making it a practical approach for widespread implementation.

While regulations surrounding PFAS levels in drinking water are still evolving, the University of Bath’s research highlights the urgent need for more stringent policies to address the threat of ‘forever chemicals.’ As awareness of the health risks associated with PFAS grows, water treatment facilities worldwide may need to adopt innovative solutions like 3D printing monoliths to ensure the safety of our water supply. The development of ceramic-infused lattices marks a significant step towards sustainable and effective water purification measures.

The utilization of 3D printing technology for the removal of PFAS from water represents a significant breakthrough in the field of environmental engineering. The innovative approach developed by researchers at the University of Bath showcases the potential of merging cutting-edge technology with environmental sustainability. As we continue to face environmental challenges, such as water contamination from harmful chemicals, it is essential to embrace innovative solutions that prioritize both efficiency and environmental impact. The future of water purification may very well be shaped by advancements in 3D printing technology, offering new possibilities for safeguarding our most precious resource – clean water.

Leave a Reply