The field of renewable energy has seen significant advancements over the years, with a focus on technologies such as photovoltaics, wind turbines, and hydro-power generators. However, one alternative solution for combating climate change involves converting excess or waste heat into electricity using thermoelectric power generation. This method relies on materials with valuable thermoelectric properties to generate electrical potential when exposed to high temperatures on one side and colder temperatures on the other. While promising thermoelectric materials have been identified, the design and fabrication of optimum module structures pose challenges that limit their real-world integration.

Researchers at various institutes, including Pohang University of Science and Technology and the George Washington University, recently introduced a new strategy for designing thermoelectric materials based on copper selenide (Cu2Se). This innovative approach, detailed in a paper published in Nature Energy, aims to create high-power generation materials that are easier to reproduce on a large scale. Traditionally, thermoelectric devices consist of p- and n-type semiconductor legs arranged in a thermocouple configuration. However, the design of these legs is crucial for optimizing thermal and electrical resistances to maximize power generation.

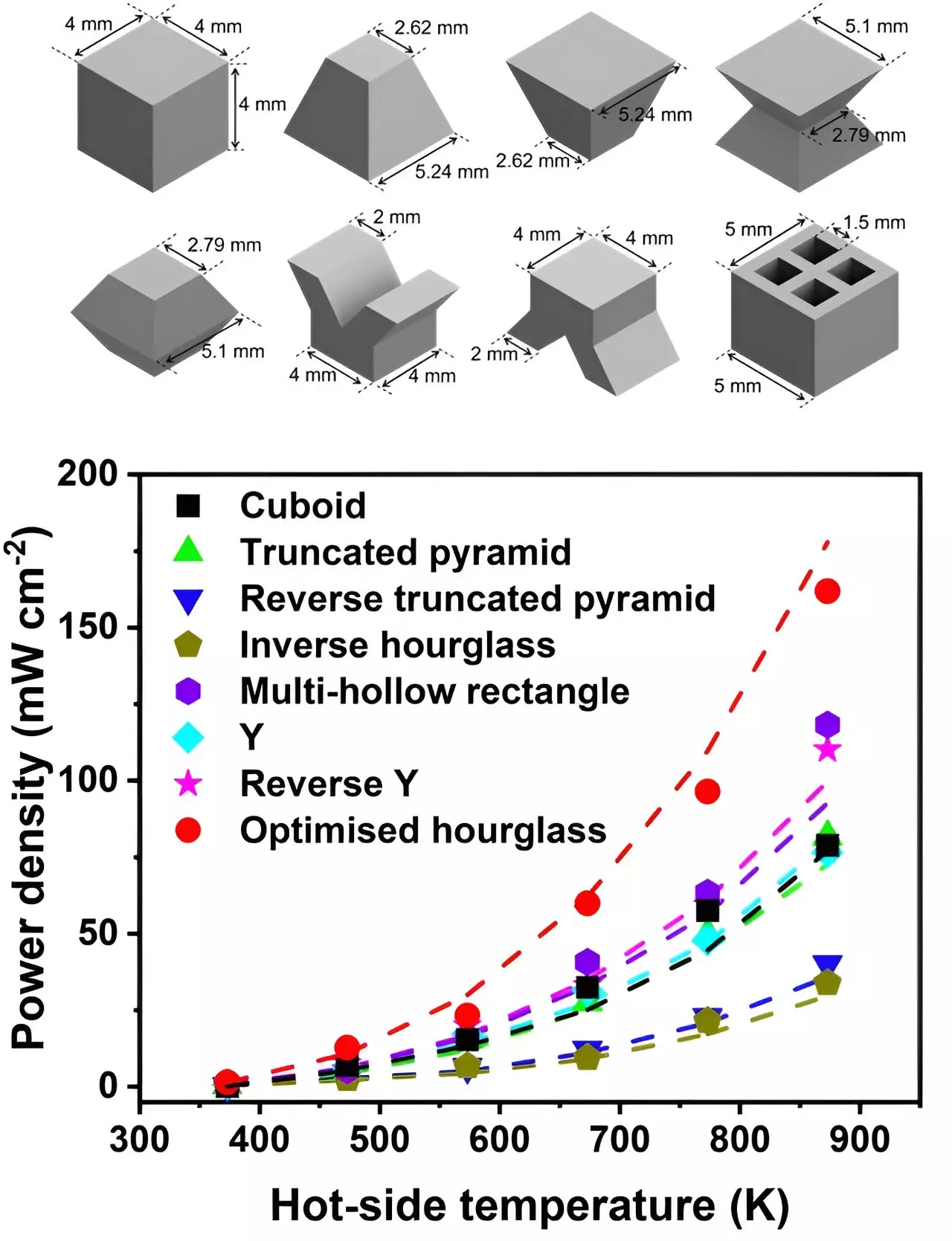

In 2020, a research team led by Prof. Saniya LeBlanc at the George Washington University explored the influence of semiconductor leg geometry on thermoelectric performance through simulations. To further investigate the impact of non-cuboid geometries, the team conducted experiments using 3D printing techniques. By designing and fabricating non-cuboid geometries for the semiconductor legs, they were able to assess the performance of these designs in generating power.

The experiments revealed that certain non-cubic legs, such as those with an hourglass-shaped geometry, demonstrated the highest power generation output and efficiency. Additionally, controlled liquid-phase sintering was found to reduce the thermal conductivity of Cu2Se, leading to enhanced ZT values of up to 2.0. These findings highlight the importance of 3D geometry in influencing the electrical current generated by thermoelectric materials.

Future Applications

While the study specifically focused on Cu2Se-based materials, the researchers believe that their strategy can be applied to other thermoelectric materials in the future. By incorporating non-cuboid geometries in segmented devices and Peltier cooling modules, they aim to further enhance the performance of thermoelectric power generators without altering their intrinsic properties. This innovative approach has the potential to revolutionize the field of thermoelectric power generation.

The impact of 3D geometry on thermoelectric materials cannot be understated. Through meticulous design and experimentation, researchers have uncovered the significant role that geometry plays in maximizing power generation efficiency. As advancements continue in this field, we can expect to see further improvements in thermoelectric power generation and its contribution to sustainable energy solutions.

Leave a Reply