In a recent study by scientists from Tokyo Metropolitan University, a new model for disordered materials was created to investigate how amorphous materials resist stress. By treating groups of atoms and molecules as squishy spheres with varying softness, the researchers aimed to gain insights into the mechanisms behind force chain formation in these materials. This innovative approach allowed them to uncover unexpected differences between harder regions and areas of concentrated forces, leading to the discovery of elongated force chains within the material.

When it comes to constructing durable materials, simply using hard ingredients is not enough. For instance, in the case of concrete failing during seismic events, the forces generated tend to concentrate in specific locations, resulting in the formation of cracks. The transmission of forces through amorphous solids like concrete is known to follow pathways called “force chains.” Understanding the emergence of these force chains is crucial in comprehending how such materials respond to stress and strain.

Modeling Amorphous Materials for Insightful Results

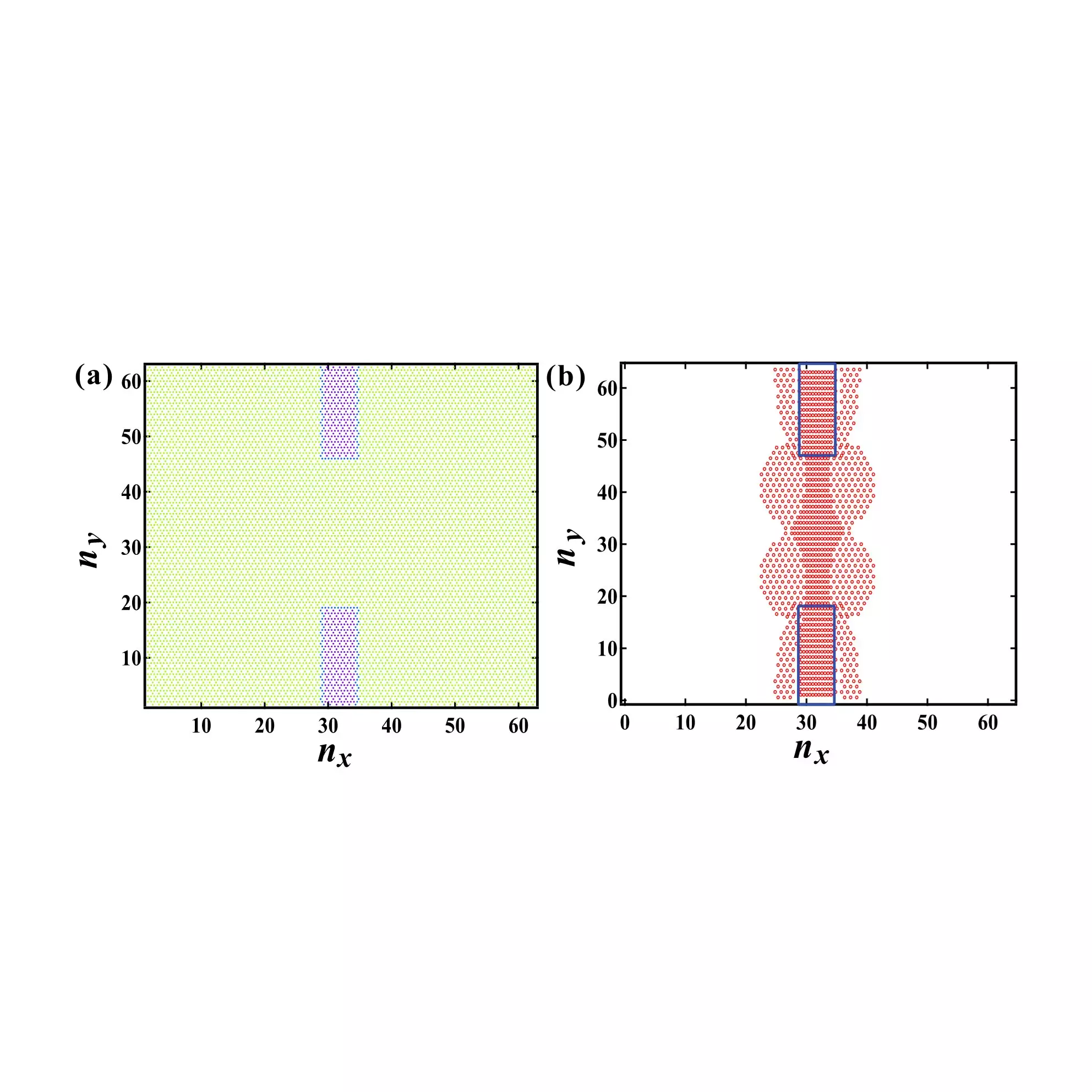

The team of researchers, led by Professor Rei Kurita, developed simple models of amorphous materials to shed light on the formation of force chains. Rather than simulating the movement of all individual atoms within a material, they represented groups of atoms with spheres of varying stiffness. This approach enabled them to observe how different regions of varying softness contribute to the overall behavior of the material under stress.

Initially, the researchers observed a correlation between harder regions within the material and the transmission of force chains. However, upon further analysis, it was discovered that force chains exhibit a more string-like shape and are not directly associated with isolated hard regions. By studying a simplified model of two stiff regions separated by a softer region, the team found that the densification of the softer region plays a crucial role in sustaining force chains.

Impact of Softness Variations on Material Properties

The study revealed that larger variations in softness and broader soft/hard regions result in softer materials overall. Additionally, greater variations in local density were found to influence the stiffness of the material. Ultimately, the research suggests that amorphous materials with a more uniform stiffness distribution tend to be harder due to the more even distribution of force chains throughout the material.

Implications for Material Design and Development

While the emergence of stiffness variations in real-world materials remains unexplored, the team’s new model and mechanism offer a promising path towards designing better materials. By understanding the fundamental mechanics of force chain formation in amorphous materials, researchers and engineers may be able to develop innovative strategies for enhancing the durability and performance of a wide range of materials.

Leave a Reply