3D-printed concrete technology is rapidly gaining popularity in the construction industry due to its efficiency, cost-effectiveness, and design flexibility. However, the limitations of printable materials have raised concerns regarding sustainability and durability. In a groundbreaking study led by engineers at the University of Virginia School of Engineering and Applied Science, the potential of cellulose nanofibrils as an additive to enhance 3D-printed concrete technology has been explored.

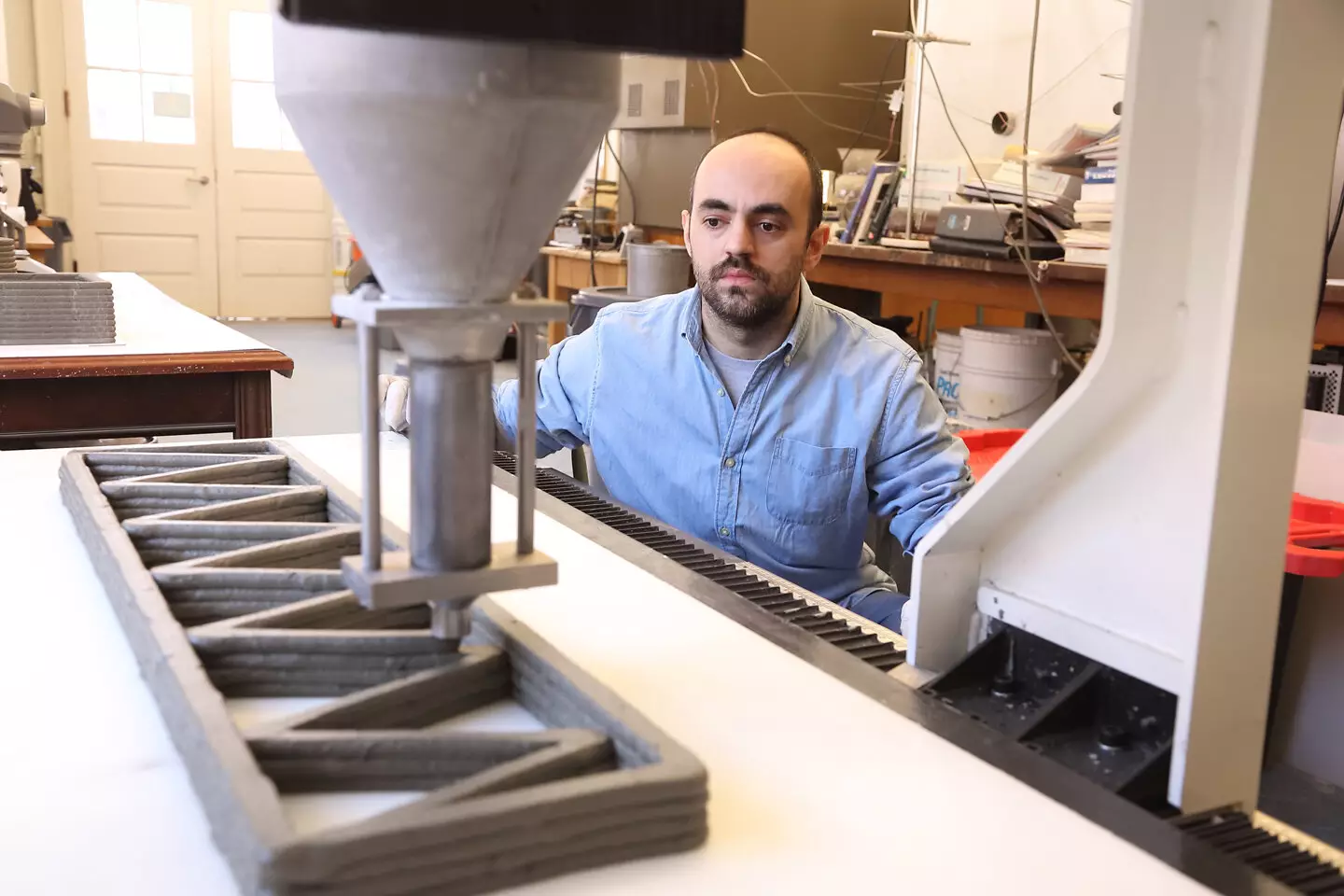

Cellulose nanofibrils, derived from wood pulp, offer a renewable and low-impact alternative to traditional additives. Known as CNF in the industry, this plant-based material has shown promising results in improving the flow properties and mechanical strength of composites. Despite its potential, the influence of CNF on conventional 3D-printed composites was not clear until the UVA-led team’s rigorous study in the Resilient and Advanced Infrastructure Lab.

Through meticulous experimentation with varying amounts of CNF additive, the research team discovered that incorporating at least 0.3% CNF significantly enhanced the flow performance of the printable material. Microscopic analysis of the hardened samples demonstrated improved material bonding and structural integrity. Furthermore, CNF-enhanced 3D-printed components exhibited superior resistance to pulling, bending, and compression tests in Ozbulut’s lab.

The findings of this study have substantial implications for the future of 3D-printed concrete technology in the construction industry. By leveraging the benefits of cellulose nanofibrils, construction practices can become more resilient and eco-friendly. The ability to enhance mechanical strength, interlayer bonding, and flow properties of 3D-printed structures through CNF additives opens up new possibilities for sustainable construction practices.

The research conducted by the University of Virginia School of Engineering and Applied Science highlights the vast potential of cellulose nanofibrils in revolutionizing 3D-printed concrete technology. By addressing the current limitations of printable materials and introducing sustainable additives like CNF, the construction industry can move towards more efficient, cost-effective, and environmentally conscious practices. As the demand for innovative construction solutions grows, the incorporation of cellulose nanofibrils could play a vital role in shaping the future of the industry.

Leave a Reply