The production of aluminum is not only a valuable industrial process but also a significant contributor to environmental waste. Every year, approximately 180 million tons of toxic red mud are generated from aluminum production. However, scientists at the Max-Planck-Institut für Eisenforschung have made a groundbreaking discovery. They have found a relatively simple way to produce green steel from this aluminum waste, which could revolutionize the steel industry and significantly reduce carbon emissions. This article explores the innovative process and its potential benefits for both the environment and the economy.

The conventional disposal of red mud is not only costly but also harmful to the environment. Countries like Australia, Brazil, and China resort to drying and disposing of this waste in gigantic landfill sites. Unfortunately, heavy rainfall can wash away the red mud, spreading toxic contaminants, and strong winds can carry it as dust particles. Moreover, the highly alkaline nature of red mud corrodes landfill walls, leading to leaks and environmental disasters. However, the researchers at the Max-Planck-Institut für Eisenforschung have demonstrated how this waste can be utilized as a valuable raw material in the production of steel.

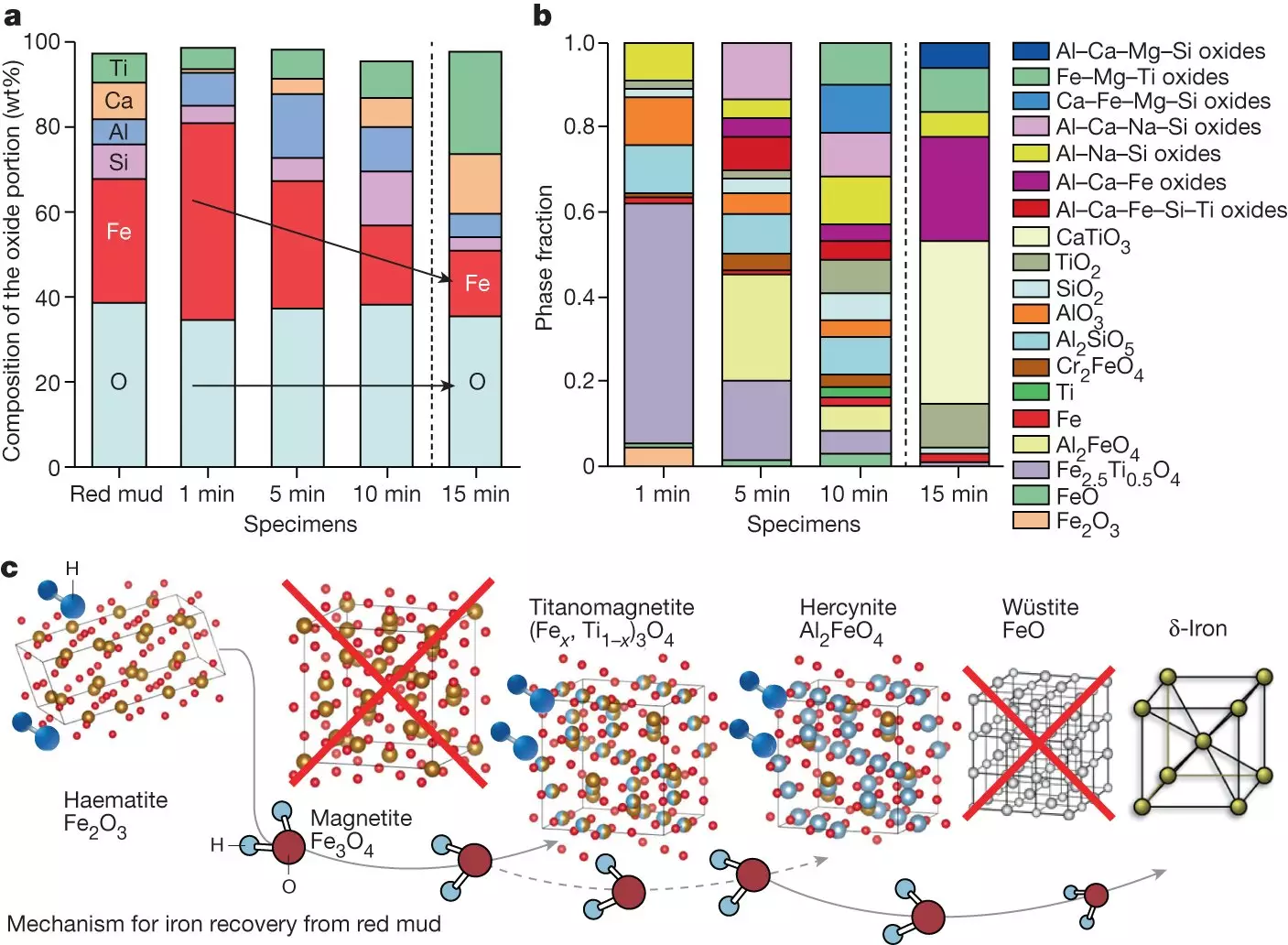

In their study published in the journal Nature, the Max-Planck team outlines their groundbreaking process for transforming red mud into steel. By melting the red mud in an electric arc furnace, they are able to convert the iron oxide within the waste into pure iron using hydrogen plasma. This plasma reduction process takes only ten minutes and results in the separation of liquid iron from the liquid oxides. The extracted iron is of such high purity that it can be utilized directly in steel production. The remaining metal oxides solidify into a glass-like material that can be used in various construction applications. This innovative approach not only eliminates CO2 emissions but also neutralizes the heavy metals present in the red mud.

The potential benefits of this green steel production process are significant. Given that 4 billion tons of red mud have accumulated worldwide, the Max Planck team estimates that nearly 700 million tons of CO2-free steel can be produced. This accounts for approximately one-third of the annual global steel production. Moreover, by using green hydrogen as a reducing agent, the process avoids the highly contaminated iron and substantial CO2 emissions that result from other approaches such as using coke. The reduction of CO2 emissions by 1.5 billion tons in the steel industry is a remarkable achievement that can significantly contribute to mitigating climate change.

Aside from its environmental advantages, the green steel production process also proves to be economically viable. The Max-Planck team conducted a cost analysis, which revealed that the process becomes profitable when the red mud contains at least 50% iron oxide. Even when considering the costs associated with red mud disposal, as low as 35% iron oxide content is sufficient to make the process economically viable. By using green hydrogen and electricity from partially renewable sources, the resulting iron can compete on the market with a proportion of 30 to 40% iron oxide. These estimates may even be conservative, as the costs for red mud disposal are likely calculated rather low.

One notable advantage of the green steel production process is its practicality. Electric arc furnaces, the key equipment used in this process, are already widely used in the metal industry, including aluminum smelters. Therefore, minimal investment is required for many industries to adopt this more sustainable approach. This makes the transition to green steel production more accessible and feasible for various stakeholders.

As the demand for steel and aluminum continues to grow, it is crucial to find more sustainable and environmentally friendly production methods. The discovery of green steel production from aluminum waste offers a promising solution. Not only does it reduce carbon emissions and mitigate the environmental impact of red mud disposal, but it also demonstrates economic viability. The Max-Planck-Institut für Eisenforschung’s research opens up new possibilities for the steel industry and provides hope for a greener and more sustainable future.

Leave a Reply