The construction industry is notorious for its excessive resource consumption and the generation of significant amounts of waste. Two prevalent waste products in construction are construction-generated sludge (CGS) and construction-generated surplus soil (CGSS). While these materials can be repurposed for various applications, their highly alkaline nature poses a risk to soil and water contamination, posing a threat to plant and animal life. Additionally, the improper disposal of CGS and CGSS exacerbates the already daunting challenges of waste management. In response to this pressing issue, a team of researchers from the Shibaura Institute of Technology in Japan, led by Professor Shinya Inazumi, recently published a study proposing a novel and cost-effective strategy for utilizing CGS – “aeration curing.”

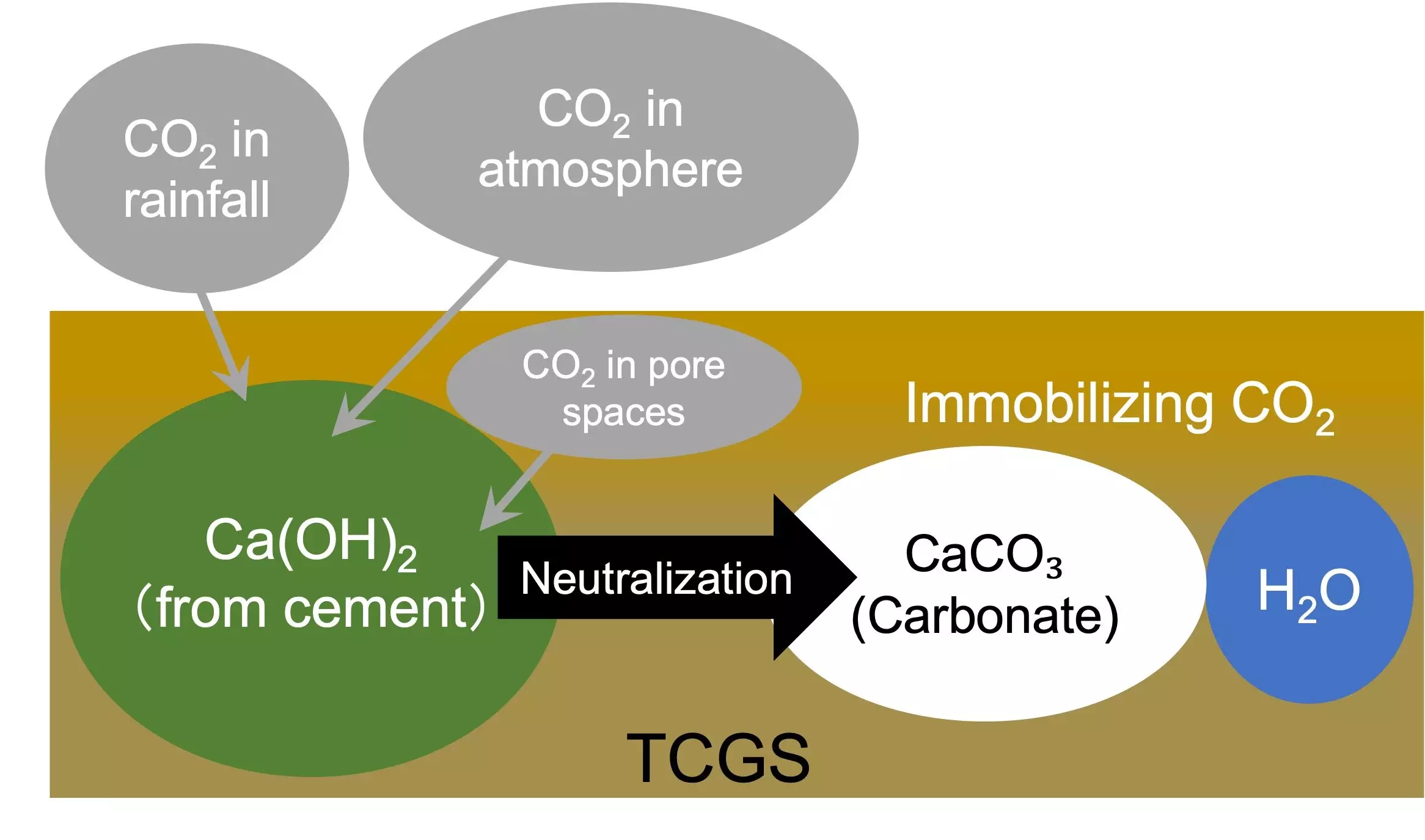

Aeration curing involves the reaction of carbon dioxide with alkaline calcium hydroxide in CGS to produce calcium carbonate, resulting in a reduction in alkalinity. What sets this method apart from conventional treatments is the reduced need for additional neutralizers, such as sulfuric acid. This significant advantage not only improves the efficiency of the process but also reduces costs. To explore the effectiveness of aeration curing, the researchers conducted experiments in various conditions, manipulating factors such as agitation speed, curing within a drying oven, the surface area of the aerated region, and the introduction of a neutralizer.

The research yielded promising results, revealing that higher agitation speeds, curing in a drying oven, and a larger aerated surface area led to a more pronounced reduction in pH. Furthermore, the aeration curing process required less neutralizer compared to traditional methods. These findings highlight the potential of aeration curing as a sustainable practice for managing CGS and achieving carbon sequestration, addressing the environmental concerns associated with the construction industry.

The implications of this study extend beyond waste management in construction. The ability of the proposed method to neutralize soil has potential applications in land reclamation and remediation projects. By preparing acidic or contaminated land for construction or agricultural use, aeration curing can play a vital role in increasing soil yields and improving overall soil health. Additionally, incorporating this approach into academic curricula and research projects can promote sustainable waste management practices and contribute to the advancement of environmental science and engineering.

Professor Inazumi emphasizes the alignment of aeration curing with the sustainable development goals (SDGs) and its potential to influence policymakers in promoting sustainable waste management and carbon sequestration practices. By demonstrating the feasibility and efficacy of aeration curing, regulations and guidelines related to construction and environmental protection can be influenced positively. However, further refinement of theoretical models is necessary to accurately reflect real-world neutralization reactions.

Aeration curing presents a promising technique for neutralizing soil and achieving carbon sequestration in the construction industry. This innovative approach addresses the challenges of waste management and contributes to the sustainable development goals. By reducing the reliance on additional neutralizers and providing cost-effective solutions, aeration curing holds significant potential for revolutionizing construction practices while minimizing environmental impact. Through continued research and implementation, the construction industry can adopt more responsible and environmentally friendly practices, promoting a greener future.

Leave a Reply