Chemists at the University of Amsterdam have developed an innovative method for introducing a trifluoromethyl group to molecules containing sulfur, nitrogen, or oxygen atoms. This breakthrough, detailed in a publication in Science, marks a significant advancement in the field of organic synthesis by eliminating the need for PFAS reagents. The environmentally friendly process offers a sustainable route for the synthesis of essential pharmaceutical and agrochemical compounds that benefit from the presence of the trifluoromethyl group.

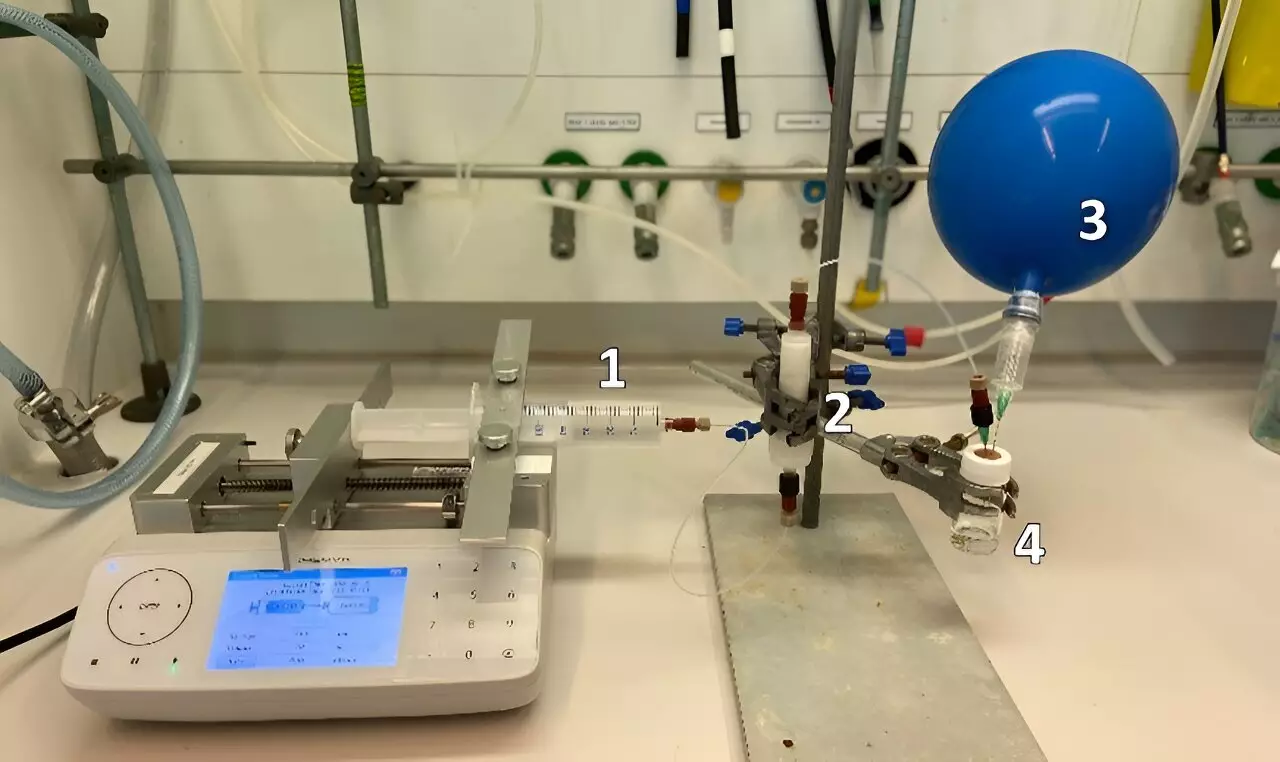

The methodology was conceptualized and refined within the Flow Chemistry group at the Van ‘t Hoff Institute for Molecular Sciences under the leadership of Prof. Timothy Noël. Collaborating with researchers from Italy, Spain, and the UK, the team successfully applied the principles of flow chemistry to enable safe and controlled reactions in closed systems of small tubes. This approach not only enhances the safety and precision of chemical processes but also provides a higher degree of flexibility and efficiency as compared to traditional methods using standard glassware.

Pharmaceutical and agrochemical compounds, such as anti-depressants and pesticides, often rely on the incorporation of a trifluoromethyl group to enhance their properties. This modification increases hydrophobicity, metabolic stability, and overall efficacy of the compounds, consequently reducing the required dose or concentration for therapeutic or agronomic purposes. While conventional synthesis methods necessitate the use of specialized fluorinated reagents, many of which belong to the problematic PFAS family, the new protocol eliminates this dependency by utilizing only cesium fluoride salt as the fluorine source. This PFAS-free approach not only aligns with environmental regulations but also offers a more sustainable option for the production of pharmaceuticals compounds.

The advanced synthesis protocol enables the attachment of the CF3 group via sulfur, nitrogen, or oxygen atoms, yielding unique fluorinated motifs that can significantly impact the properties of drug molecules and agrochemicals. By leveraging a microfluidic flow module, reactive N-, S-, and O-CF3 anions are generated in a packed bed flow reactor, facilitating efficient fluorination of suitable precursors. The high surface area of the cesium fluoride salt in the reactor, coupled with improved mixing of organic intermediates, ensures high conversion rates and purity of the final products. Importantly, the system’s design promotes safe handling of all intermediates within the closed microfluidic setup, enhancing operational safety and containment.

The integration of the anion generation module with a downstream reaction module paves the way for a streamlined platform for the derivation of molecules featuring N-, S-, and O-CF3 motifs. This innovative approach not only streamlines the process of generating fluorinated products but also enhances the properties of pharmaceutical and agrochemical active ingredients. The researchers highlight the successful combination of various anions with diverse substrates to produce a range of fluorinated products with relevance to pharmaceutical and agrochemical applications. With promising operational parameters and compelling results, this methodology shows great potential for implementation in both academic research and industrial processes, setting a new standard for green and efficient chemical synthesis.

Leave a Reply